Unleash your creativity: Print your own Pikmin with professional metal 3D printing

Suitable for Nintendo’s beloved fans Piquemin These fascinating plant-like creatures represent not only digital companions, but also symbolize adventure, strategy, and nostalgia. Now imagine a tangible, detailed metal version of your favorite Captain Pikmin or Squad and make custom designs and crafts for you. With advanced metal 3D printing, this dream can be realized. At Greatlight, we focus on transforming digital concepts into durable, high-precision reality with our cutting-edge rapid prototyping services. Let’s explore how to create your own custom Pikmin numbers and why the metal additive manufacturing industry revolutionizes the collection.

The Science Behind Magic: How Metal Parkin Comes Life

1. Design Piquemin:

It all starts with carefully crafted digital models. Whether tuning the fan-made STL file or working with our design team, we prioritize anatomical precision, i.e. the iconic spherical head, expressive stems, and delicate limbs of the delicate Pikmin type (red, blue, blue, yellow, and even custom hybrid). Using parameter modeling software, we perfect structural integrity to ensure that easily fragile features such as thin legs or tentacles are subject to printing stress.

2. Material selection:

The possibility of unlocking of metal 3D printing cannot be matched. Greglight offer Stainless steel 316L For flexibility and lightning, Titanium (Ti6al4v) For the lightweight power, Aluminum alloy Affordability. Each material is rigorously tested for biocompatibility and environmental stability – your Pikmin does not gradually disappear or degrade over time.

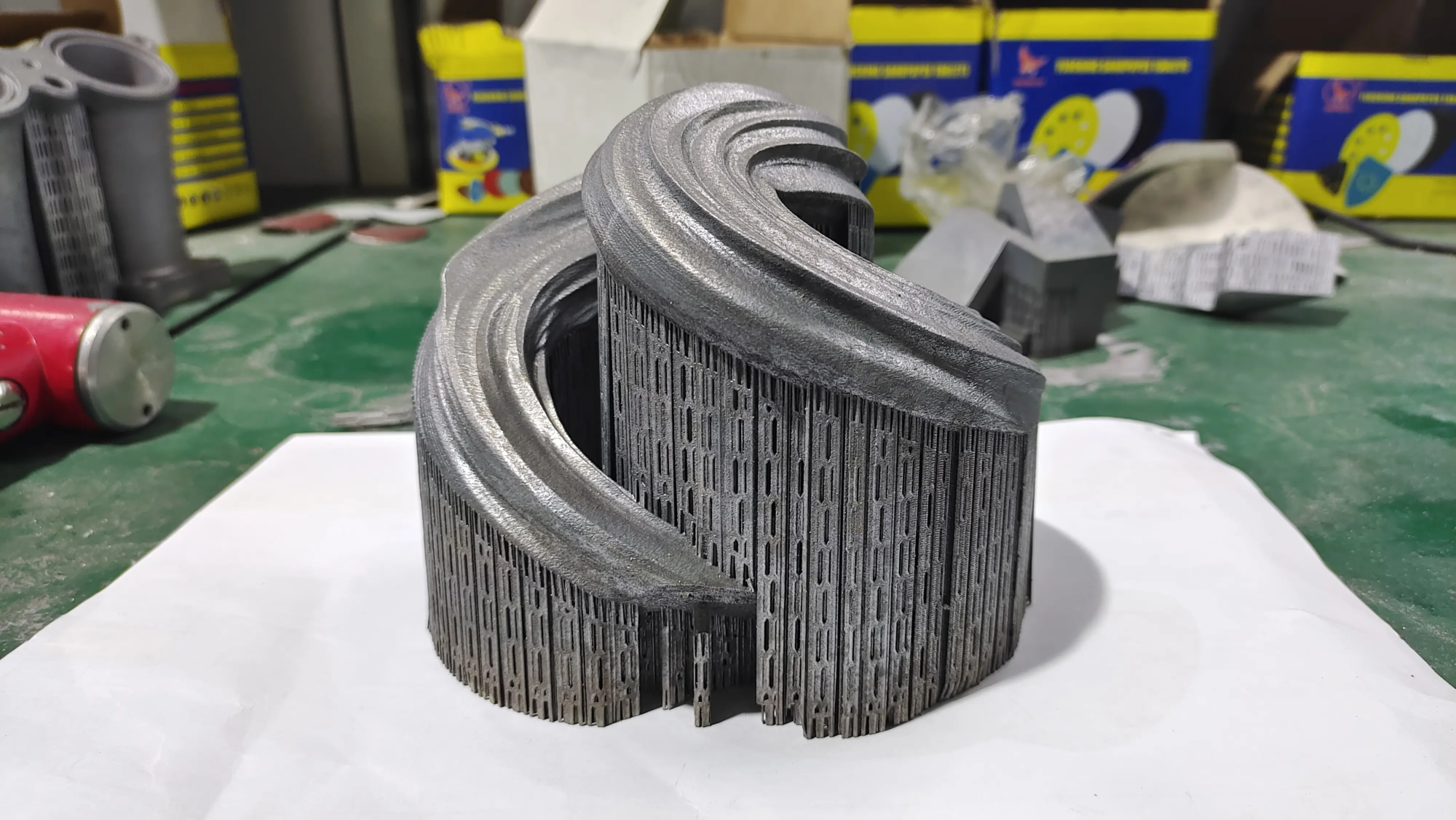

3. SLM Revolution:

In Greatlight, Selective laser melting (SLM) Technology powers our processes. Based on your model, high-precision laser micro-welded metal powder layer (to 20 microns) achieves details greater than 50 µm. This industrial-grade approach ensures density exceeds 99.7%, eliminating the common structural weaknesses in budget FDM/plastic printers. We keep the printing chamber atmosphere below 0.1% oxygen to prevent oxidation and ensure metallurgical perfection.

4. Excellent post-processing:

Raw metal prints have exquisite finishes:

- Pressure preference: Heat treatment prevents deformation.

- Support removal: The CNC auxiliary detachment retains surface quality.

- Surface reinforcement: Bead explosion, mirror polishing or custom texture (e.g. matte "Leafy" stem).

- Color options: Anodized (titanium/aluminum) or ceramic coating for vibrant, long-lasting tones.

Why Greatlight excels in making Pikmin

As China’s leading rapid prototyping manufacturer, Greatlight combines Advanced SLM 3D printer and ISO certified production plan. Our edge is:

- speed: Rush Services provides prototypes within 48 hours.

- Proportional flexibility: From a 5 cm Pikmin statue to a squad of 100 units.

- Accuracy tolerance: ±0.05 mm accuracy, which is crucial for complex facial features.

- End-to-end solution: Design support, printing, finishing and assembly – all under one roof.

Whether you are an amateur looking for unique table decorations or game studio prototype merchandise merchandise, we can tailor solutions that violate conventional manufacturing restrictions.

Real-world application: Beyond the fanaticism

Custom Metal Parkmins surpass fanatics – They showcase the potential of SLM:

- Educational tools: Biology teachers use models to demonstrate plant-based hybrids.

- Project Demo: The miniaturized Pikmin illustrates the load distribution in lightweight structures.

- Jewelry: Titanium Pickmin Pendant, combining whimsical with hypoallergenic durability.

in conclusion

Printing your own metal Pikmin is more than just having a game history, which is a testament to how far additive manufacturing has evolved. Greglight Bridges’ imagination and industry-level execution, delivering a collection that’s as solid as they’re charming. By leveraging our SLM expertise, an extensive material library, and a commitment to precision, your custom Pikmin is a timeless artifact. Ready to bring your vision to life? Explore endless possibilities with fast prototyping to redefine quality.

FAQ

1. Can I use my own 3D Pikmin model?

Absolutely! We support STL, OBJ or step files. Our engineers will optimize your metal printing design (e.g., reinforce thin sections) and ensure manufacturability.

2. The durability of metal-printed Parkmin?

Extremely durable. Titanium or stainless steel resists corrosion, impact and ultraviolet degradation and other materials. They are ideal for outdoor displays or high flow areas.

3. What is the typical turnaround time?

For standard orders: 5-7 days (including design review, printing and completion). Extended service is available within 48-72 hours.

4. Is there a tinted finish?

Yes. We provide anodization for aluminum/titanium (created in blue, gold, purple) and stainless steel paints. The color is baked to the surface instead of being coated.

5. Is there a minimum order quantity (MOQ)?

No Orders – We produce single prototypes for batch processing. Pricing scales transparently with volume.

6. How do I start a project?

Submit your design via the Greatlight online portal for free quotes. Our team will propose optimizations and material choices within 24 hours.

Unlock accuracy, creativity and endurance – Good pikmin with good lights that can stand the test of time. Ask your offer today and redefine the rapid prototyping.