Making your own Star Wars X-Wing: 3D Printing Master Class

For Star Wars fans, engineering enthusiasts and collectors, the X-wing fighter symbolizes the pinnacle of science fiction design, an icon of rebellion and innovation. Creating your own detailed, high-fidelity X-wing replicas with modern 3D printing technology is not only possible. It was an exciting technical adventure. This guide will take you through the entire journey and explore how to be professional Metal additive manufacturing Turn fan dreams into tangible masterpieces.

Why 3D printing X-wings?

- Personalization: Modify the proportions, details, and even add LED lights for overspeed driving effect.

- Durability: Metal printed models handle better than plastic.

- History nods: Reconstructing Luke Skywalker’s Red Five or Poe Damelon’s Black.

- Engineering Challenges: Great for honing CAD skills or learning post-processing techniques.

X-wing’s step-by-step journey

1. Design and document preparation

Start with an off-the-shelf X-wing model in repositories like Thingiverse or Cults3D. For originality, use CAD tools such as Fusion 360 to engrave custom details. Key Check:

- Thick wall: Ensure the stability of metal printing ≥1.2mm.

- support: Develop overhangs (e.g., laser cannons) to minimize post-print cleaning.

- scale:Balance details with printing costs – 6–12 inches is ideal for desktop display.

2. Material selection

Metal 3D printing unlock studio quality results:

- Stainless steel (316L): Budget-friendly, corrosion-resistant, perfect for painting.

- Aluminum (ALSI10MG): Lightweight, with excellent thermal characteristics for engine details.

- Titanium (Ti6al4v): High-quality strength to weight ratio for complex moving parts.

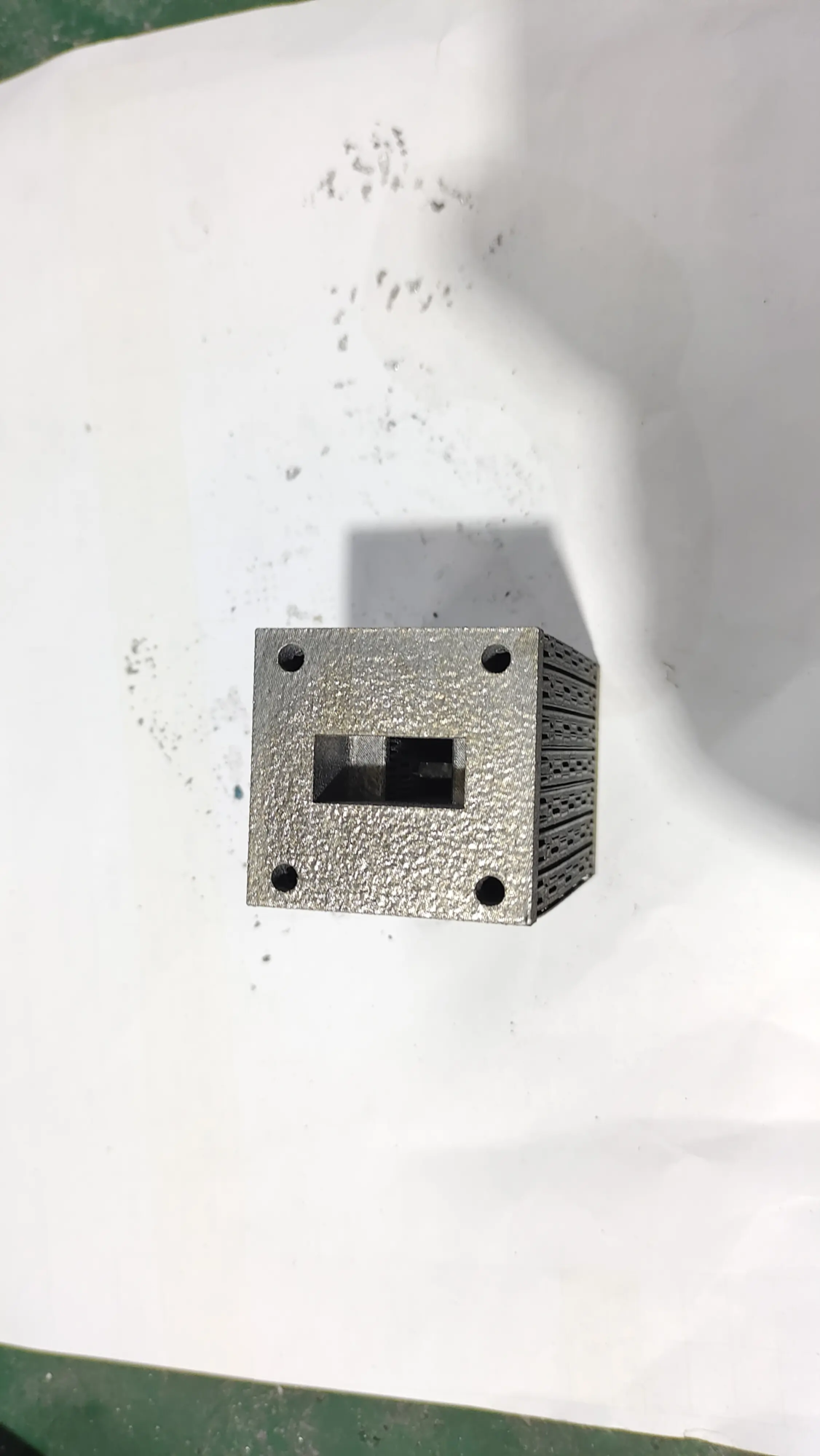

Why metal? Unlike brittle plastics, metals endure stress and allow functional components such as rotating wings. In the context, Greatlight’s SLM (Selective Laser Melting) printer fuses at a fusion layer of up to 20 μm, matching the Lucasfilm Studio model.

3. Printing: Accuracy is important

Amateur FDM printer fights with thin wings and rounded surfaces of X-wings. Industrial SLM technology is good at:

- A layer of laser sintering prevents distortion.

- Complex internal equipment (e.g., cockpit details) are printed without assembly gaps.

- Greglight Pro-Tip: Orient the model 45° to reduce support scars on visible surfaces.

4. Post-processing: Art encounters engineering

This stage separates works worthy of display from amateur prints. Professional Services One-stop completion from Greglight include:

- Support deletion: The part with weak cuts of CNC.

- Smooth surface: For steam polishing similar to glass, or for bead blasting in matte realism.

- Enhanced:

- Painting and copper green: Use ceramic paint to achieve accurate weathering of the screen.

- assembly: Brass components that integrate landing gear or cannon.

- Electrification: Embedded micro-leader for wiring channels with CNC drilling.

Why collaborate with professional rapid prototyping services?

Print iconic model requirements Industrial Accuracy– Hobby machines are rarely delivered. Greglight Bridge Gap:

- Advanced SLM printers:8-ray system is used for 5 times construction without sacrificing 30μm accuracy.

- Material versatility: Print in everything from copper alloy to tool steel.

- End-to-end expertise: From topological optimization to heat treatment – all under one roof.

- Speed and scale: Rush 72 hours of prototype or batch run.

"Our engineers once made a 2-foot-long titanium X-wing with a functional S-core that moved through a printed hinge. Customers even commissioned electric displays to entrust conductive copper versions!"

– Great technical team

in conclusion

3D Print Your Star Wars X-wings blend fantasy with cutting-edge technology. Although the DIY kit can be nostalgic, Metal additive manufacturing provides heirloom quality collections– Enough to withstand the asteroid field (or curious hand). For insurgents seeking perfection, work with experts to ensure that your red five is not only printed; it has met legacy standards.

Ready to start your project? Greatlight combines aerospace-class SLM printers with artistic finishes to turn the Blueprint into a squadron-ready Starfighter. [Contact us] Quote today!

FAQ

1. Is it legal to 3D printing of Star Wars X-Wing?

Yes, yes Personal use. Selling replicas that infringe on Disney/Lucasfilm copyright. Always verify licenses for commercial projects.

2. How much does it cost to print a metal X-wing?

Prices range from $150 (4-inch steel model) to $5,000+ (titanium with electronics). Complexity, size and completion determine the final cost.

3. Can I print moving parts?

Absolutely! SLM printing creates interlocking joints. Gremplys usually integrate hinges that open the wing or rotate the cannon.

4. Which file format do you accept?

STL or OBJ files are ideal. Our team should be requested to optimize the design of the design.

5. Durability of metal printing models?

Stainless steel survives better titer than PLA plastic. The titanium variant endured decades of display without deteriorating.

6. Do you deal with painting/assembly?

Yes – Our one-stop service includes primer, spray gun, plating and complete assembly. Share the screen’s precise weathered reference image.

7. What is the lead time?

The prototype will be shipped within 3-5 days. Complex projects with completed take 2-3 weeks.

8. Can you expand your model to jewelry size?

We have printed 2cm X-wing pendant with gold-plated brass! Miniaturization is a professional.

Greglight is an ISO 9001 certified rapid prototyping leader from China, with over 50 industrial SLM printers. We address aerospace, automotive and collectibles challenges to improve accuracy at destructive speeds. Customize your project now! 🚀