As a fan of the Star Wars series, one of the most iconic props in the series is Han Solo’s Blaster. Formal as we all know, the DL-44 Blaster has become a symbol of the personality and style of the charismatic smuggler. But have you ever wondered how to create such props in real life? With the help of advanced 3D printing technology, it is now possible to recreate Han’s Blaster with incredible accuracy and detail.

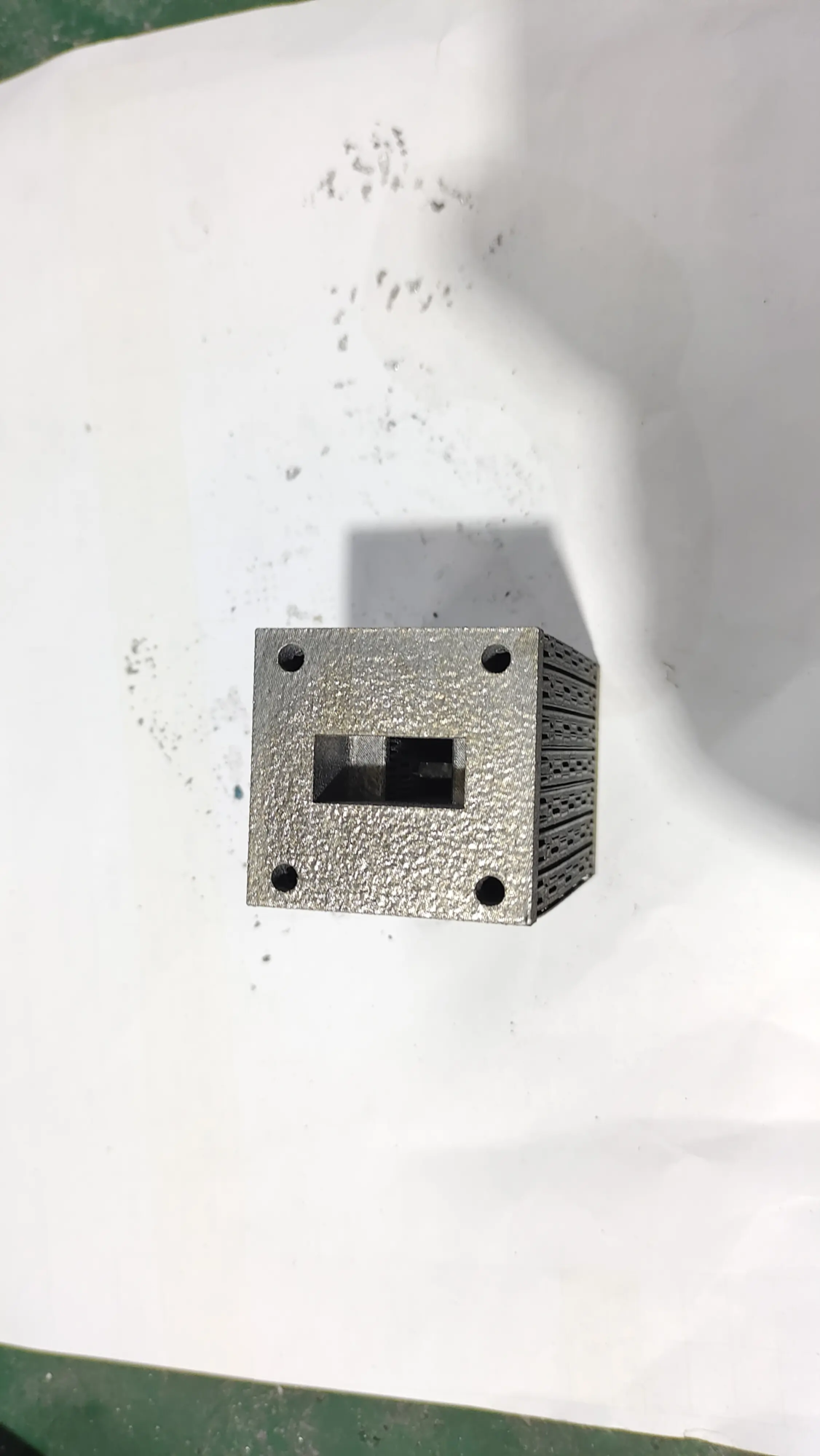

At Greatlight, a professional rapid prototyping manufacturer of Greatlight, they have advanced SLM 3D printer equipment and production technology to professionally solve rapid prototyping problems of metal parts. This means they can create complex metal parts, such as DL-44 blasters, with high accuracy and accuracy. Their one-stop post-processing and completion services also ensure the highest quality of the final product.

The process of creating a 3D printed DL-44 blaster begins with designing the model. This involves lying through the original props and creating detailed digital models to capture aspects of their design. Once the model is finished, it is sent to a 3D printer that builds the blaster from the metal powder using a layer by layer process.

SLM 3D printing technology used by Greatlight allows the creation of complex geometric shapes and internal structures that cannot be produced through traditional manufacturing methods. This means that the 3D printed DL-44 blaster can be made with incredible details and accuracy, including the complex mechanisms and components that make up the props.

One of the key benefits of using 3D printing to create a DL-44 Blaster is the ability to customize your design. Using traditional manufacturing methods, creating such custom props will be time-consuming and expensive. However, with 3D printing, the design can be changed and a unique version of the blaster reflects the personality and style of a person.

Greatlight’s expertise in custom precision machining also means they can create custom parts and components for the DL-44 Blaster. This includes triggers, ranges, and other mechanisms that make up props. Their advanced technology and production capabilities ensure high accuracy and accuracy in each section, resulting in the final product that is both functional and amazing.

In short, creating a 3D printed DL-44 Blaster is a complex process that requires advanced technology and expertise. This iconic prop can be recreated with incredible accuracy and detail with Greatlight’s professional rapid prototyping service. Whether you’re a fan of the Star Wars series or just looking for unique and impressive props, the 3D-printed DL-44 Blaster is sure to impress.

FAQ:

Q: What is 3D printing and how does it work?

A: 3D printing is the process of creating physical objects by layering materials (such as metal powder) to build the digital material of an object.

Q: What is SLM 3D printing technology?

A: SLM (Selective Laser Melting) 3D printing technology is a 3D printing that uses laser melting and fusing metal powders to create a strong and precise final product.

Q: Can I customize the design of the DL-44 Blaster?

A: Yes, with 3D printing, you can customize the design of the DL-44 Blaster to reflect your personality and style.

Q: What is the process of creating a 3D printed DL-44 blaster?

A: The process involves designing models, 3D printing of blasters, and post-processing and completing the final product.

Q: Can Greglight create custom parts and components for DL-44 Blaster?

A: Yes, Greatlight’s expertise in custom precision machining means they can create custom parts and components for the DL-44 Blaster, including triggers, ranges, and other mechanisms.

ISO 9001 Factory