Create unique magical decorations: an expert guide to 3D printing amazing snowflake patterns

Winter brings a glittering snow scene, and nothing is better than the complex snowflakes. While tailoring is traditional, 3D printing provides an incredible way to create unique, durable and sophisticated snowflake designs that are perfect for decorations, decorations, jewelry or gifts. Whether you are an amateur or a designer, this guide delves into craftsmanship and printed 3D snowflakes.

Why 3D printing snowflakes?

Unlike their temporary frozen peers or fragile paper versions, 3D printed snowflakes are enduring artworks.

- Unlimited design freedom: Create surreal crystal replicas or abstract geometric fantasies through other methods.

- Durability: Printed plastics (PLA, PETG, resin) or metals withstand treatment and seasonal display.

- Size and Complexity: From intricate earrings to large window hanging scale designs. 3D printing easily handles complex interlocking details.

- Perfect gifts and decorations: Personalized for unique Christmas ornaments, bark, garland or independent artwork.

- Repeatability: Once designed and sliced, printing the same perfect copy is simple.

How to design 3D Snowflake Patterns: From Concept to Model

- Understand snowflake symmetry: Real snowflakes show hexagonal symmetry. Most 3D models take advantage of this by designing a single segment (usually 60-degree or 120-degree slice) and copying it using the rotational symmetry tool in the CAD software. Radial symmetry produces a balanced naturalistic form.

- Select your weapon (software):

- Beginner friendly: Tinkercad (web-based, intuitive) is great for starting with basic shapes and combining them.

- Advanced Accuracy: Fusion 360, Solidworks, Blender or Freecad allows the creation of complex curves, detailed patterns and precise controls to provide for complex branches, dendrites and surface textures. Parameter design is ideal.

- Generate design: Tools such as OpenSCAD (code-based) enable algorithmic patterns, creating mathematically perfect uniqueness.

- Design principles:

- branch: Start with the central hub. Add the main arm and then assist the branch. Different branch angles, lengths and thicknesses.

- Details are key: Add filaments, ridges, dents, holes (for strings/lights) and surface textures (imitate the ice crystal surface). Use Boolean operations to shape the shape.

- Thickness is important: Make sure the arm wall is thick enough to fit the selected printing material (pla ~ 1.5 mm, resin can be finer). Avoid overly thin features, which become fragile.

- Connection point: If you plan to hang snowflakes or attach multiple sheets, design rings, labels, or built-in holes. Make sure these points are strengthened.

- Looking for inspiration: Check out the macro snowflake photography by Wilson Bentley or Kenneth Libbrecht. Plant shapes (ferns, marine life) also stimulate organic branching patterns. Many open source platforms (Thingiverse, Printables, Cults3D) offer downloadable designs for modification.

Preparing for printing: Settings and Techniques

- Material selection:

- PLA: Most common, easy to print, with a width range. Smooth filaments can mimic ice. Biodegradable.

- PETG: Stronger, more flexible than PLA, and better suits larger flakes. Available transparent/silk options.

- Resin (SLA/DLP): capture Exquisite Details, smooth finish. Ideal for small, sophisticated ornaments/jewelry. Choose transparent or pearl white resin.

- Metal (SLM): Used for high quality, long-lasting and cold to touch snowflakes (decorations, high-end decorations, jewelry pendants). Materials such as stainless steel, titanium or aluminum alloy have strength and unique aesthetics.

- Slicing strategy:

- direction: The flat side downward minimizes support. For multi-part sheets, high-detailed oriental surfaces are required.

- support: Steep overhangs are required. Tree support is generally more effective and easier to remove than standard lattice support. Minimize contact points.

- Cold adhesion: Use edges or rafts (especially for small feet/flat prints). Make sure to have a clean bed.

- Layer height: For FDM (PLA/PETG): 0.1mm -0.2mm, details are visible. For resin: 0.025mm -0.05mm captures incredible fineness.

- Speed and Cooling: Print slowly (30-50mm/s maximum exterior wall) and maximize cooling to prevent distortion and blurring details on the FDM. The resin requires careful layer exposure settings.

- filling: 15%-25% capacity or cubic filler provides good strength without adding too much weight/time.

- print: Carefully monitor the first floor. Ensure an optimized bridge setting for spans between the snowflake arms.

Post-processing your flakes: bring them to life

- FDM (PLA/PETG):

- Support removal: Carefully shear and sand residue. A heat gun (low setting!) or a quick hot air bath (convection oven with very low temperatures) can help with smooth little strings.

- Grinding and polishing: Gradually fine sandpaper (wet sandpaper helps). Polishing compounds or spray varnish (gloss) enhance clarity/gloss.

- Painting: Spray paint, acrylic, and even metal markings for details.

- Resin:

- Cleaning: thoroughly clean the IPA or official detergent (post-printing).

- After curing: cure under ultraviolet light for final hardening and stability.

- Support: carefully cut; use fine sanding. The resin sand/polishing went very smoothly.

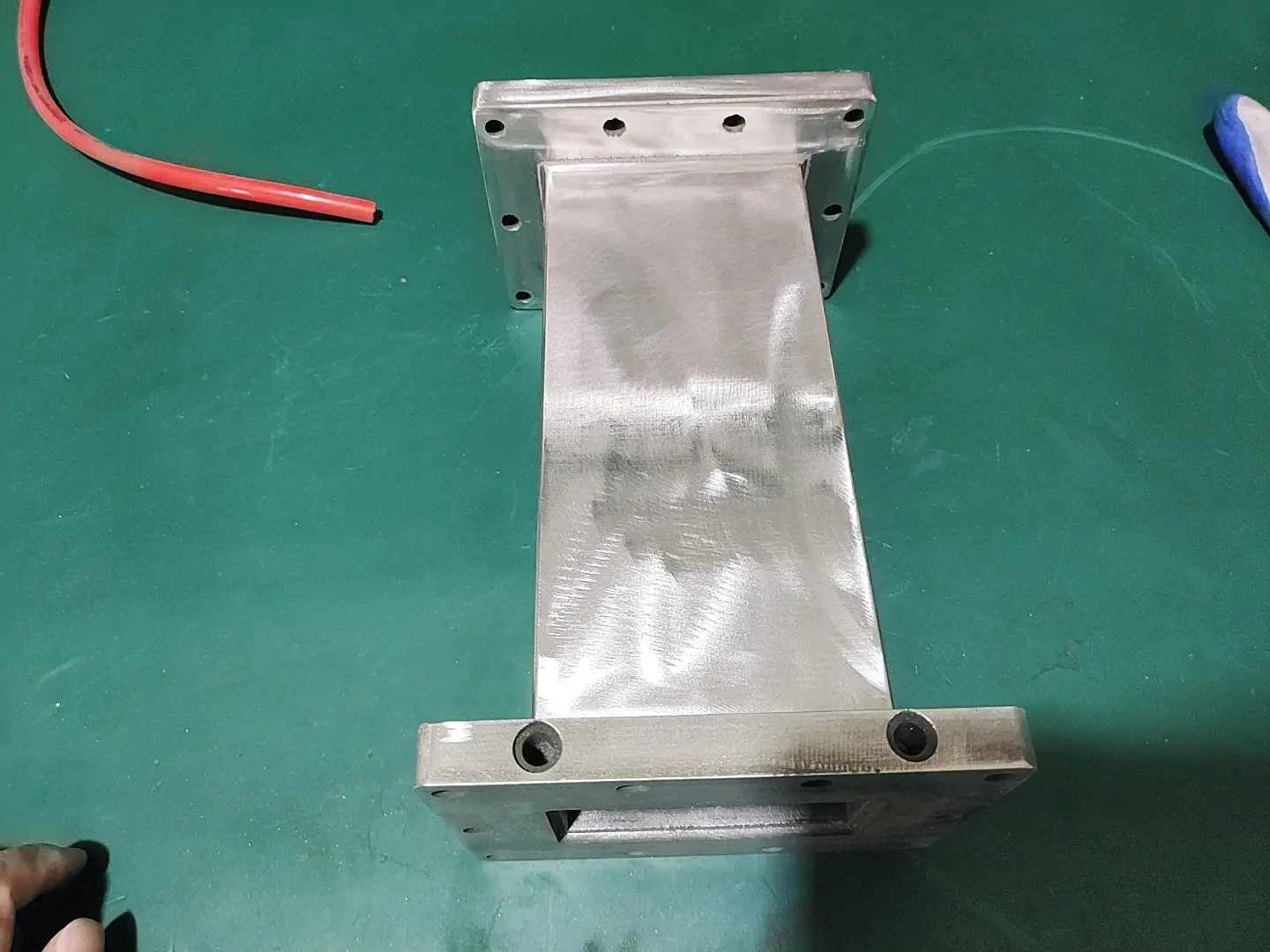

- Metal (SLM):

- Professional post-processing is crucial: Disassembly from the build board requires special wire EDM cutting. Stainless steel printing usually requires shooting, tumbling or polishing to get a smooth, finished look. Electroplating (gold, silver, rose gold) or tap (sugar-containing, etc.) provides an amazing decorative finish. Processing (for thread insertion) is possible.

- Partner expertise: For metal snowflakes, working with experienced manufacturing partners (Greatlight) ensures perfect results. Their range of functionality exceeds the standard post-printing steps, including precise machining and refined finishes tailored to the rigorous needs of complex metal designs.

Beyond Plastics: The Charm of Metal Snowflakes

While the plastic and resin snowflakes are beautiful, metal alternatives offer exceptional levels:

- Unrivaled durability: Resist rupture, temperature changes and discoloration.

- Permanent and heirloom quality: Become a lasting ornament or jewelry.

- Unique aesthetics: The cold metallic sheen (polished, matte, brush) has a distinctly different high-end feel.

- Functional strength: Suitable for larger structural decoration or parts that require mechanical stability.

Achieve perfection in metal: collaborate to gain expertise

Create exquisite Metal 3D printing snowflakes Need for industrial grade Selective laser melting (SLM) Technology and expertise. From optimizing the construction direction to prevent thermal stress warping, to the complex post-treatment required for smooth, finished surfaces, it is far from the desktop process. Great As a professional rapid prototyping manufacturer, this level of expertise can be justified.

use Advanced SLM 3D printer As well as a deep understanding of the characteristics and sintering dynamics of metal powders, Greatlight solves complexity professionally Rapid Prototyping Challenge of Metal Parts. For complex snowflake patterns, especially in materials ranging from lightweight aluminum to solid titanium or corrosion-resistant stainless steel, their ability to ensure structural integrity and amazing aesthetics. In addition to printing, Greglight provides Comprehensive post-processing and sorting services – Including stress relief, accuracy Processing For critical interfaces, polishing, bead blasting and refinement plating – Transform the raw metal part into a real work of art.

As one of the leaders Rapid prototype company from ChinaGremlight in Quickly customize and process materialstransform complex CAD design into tangible high-quality reality. For individuals, designers or businesses seeking excellence Custom precision machining Their snowflake creation service – or any quick prototype demand – works with Greatlight to ensure the best price without compromising precision or finish. Customize your precision rapid prototyping parts And explore the elegance of metal 3D printed snowflakes at Greatlight.

in conclusion

3D printing unlocks new dimensions created by snowflakes, turning ephemeral ice crystals into lasting sculptures. Whether it’s trying colorful PLA on a home printer, capturing complex details with resin, or investing in heirloom quality of metal printing through experts like Greatlight (Greatlight), the possibilities are endless. Understand hexagon symmetry, master design tools, implement smart slicing strategies, and apply the basics of proper finishing techniques to enable you to make unique winter magic. So embrace the never-melt snowflakes and explore the world of 3D printing winter wonders!

FAQ (FAQ)

Q1: Which 3D printer is best for making snowflake decorations at home?

A: For amateurs, an FDM printer (using PLA or PETG) is the easiest to obtain. Find printers that are known for good small accuracy. Resin printers (SLA/DLP) produce the best details, making them great for very complex ornaments or jewelry, but require more treatment precautions.

Q2: How to design snowflakes with rotational symmetry?

A: Almost all CAD programs have symmetric tools. Design a section of snowflakes (such as 60 degrees or 120 degrees slices) and then use the software "pattern" or "Circular pattern" Features to copy the segment around the central axis (6 times 60 degrees, 3 times 120 degrees). Copy the pattern to complete the flake.

Q3: Where can I find ready-made snowflake models?

A: Popular repositories include Thingiverse, Printables, Cults3D and Myminifactory. search "3D Printable Snowflakes" or "Snowflake decoration." Filtered by complexity, popularity and file type (.stl or .3mf).

Question 4: Why do my printed snowflakes warp or break easily (especially the arms)?

A: Warpage is usually caused by poor bed adhesion or uneven cooling (ensure bed upgrade, proper temperature, use edge/raft). Brittleness can be due to low quality fibers, printing too cold/cooling too fast or being too thin wall/thin features. Slightly increase the wall thickness on the smart arm.

Q5: Can I 3D print transparent snowflakes?

Answer: Absolutely! Use clear PLA/PETG or specialized transparent resin. It is difficult to achieve true glass-like clarity on FDM. Maximize cooling and post-processing (varnish) to improve transparency and print slowly. Resin provides better intrinsic clarity.

Question 6: How long does it take to 3D print snowflakes?

Answer: This is a big difference. A small, simple FDM snowflake can take 20-60 minutes. Large (6-8-inch) complex FDM design can take 4-8 hours. Highly detailed resin printing can take 1-3 hours. Due to the complexity of the process and post-production, metal snowflakes through SLM require a delivery time coordinated with the manufacturing partner.

Question 7: What are the advantages of metal 3D printing snowflakes compared to plastics?

A: Metal snowflakes offer unparalleled durability, long-term dimensional stability, high-end aesthetic appeal (polished, plated finish), unique cold-to-contact feel and heirloom quality. They are ideal for quality jewelry or permanent outdoor/indoor installations where plastics may degrade.

Question 8: How important is post-processing for metal snowflake printing? Can I do it myself?

Answer: Post-processing is For metal SLM parts, it is much more critical and complex. Disassembly from the build board requires a special wire cutting machine. Surface finishing (smoothing, polishing, blasting) requires professional equipment and skills to handle complex, often fragile structures without damage. Treatment may be required (such as passivation). Electroplating requires industrial settings. Working with experts like Greatlight is crucial.