Game changer on the chessboard: printing chess pieces with 3D precision

Chess is a timeless battle of strategy and intelligence that has captivated people for centuries. The works themselves—the regal king, the commanding queen, the agile knight—are symbols imbued with meaning. Yet among these iconic figures, the humble pawn often holds untapped potential for personalization and innovation thanks to the advent of 3D printing. Enter the field "printing pawn": The marriage of traditional gameplay and cutting-edge manufacturing unleashes unprecedented creative freedom and functional advantage.

Beyond the Generic Staunton: The Allure of Custom Pawns

While mass-produced chess sets are consistent, they often lack individuality. Cracked pieces, mismatched pieces, or just the desire for something unique – these are the sparks that ignite a game. "printing pawn" revolution. 3D printing removes these limitations:

- Unlimited designs: Freed from the constraints of traditional manufacturing, chess pieces can be made beyond the standard Staunton silhouette. Imagine ritual guardians inspired by ancient civilizations, tiny futuristic drones, delicate plant stems or abstract geometric shapes. Your pieces become a direct expression of your aesthetic or thematic vision for the game.

- Functional engineering: Beyond appearance, 3D printing enables smart design. Hollow chess pieces can be accurately weighed with inserts (such as steel balls) for optimal stability and feel. An internal lattice structure reduces material usage without sacrificing strength, keeping parts lightweight. Ergonomic shapes tailored for comfortable operation are possible.

- Perfect Harmony and Replacement: Accidentally lost a key piece to complete your precious set? 3D printing provides the perfect solution. By accurately replicating existing chess piece designs (either through scanning or precise digital modeling), you can recreate the perfect match and restore the chess board to its former glory. This extends perfectly to the design of the entire custom suit, where each piece complements the aesthetic of the custom pawn.

Metal Chess Pieces: Improves durability and reputation

While polymers (PLA, ABS, resins) provide versatility and color to home printers, Metal 3D printing Take pawn heft, durability and prestige to a whole new level. This is what advanced rapid prototyping makers love huge light Really shine.

- Unparalleled feeling: Metal chess pieces have a lot of weight and provide a sturdiness that plastic cannot match. The tactile feel of moving solid metal blocks enhances the seriousness of every decision on the board.

- Lasting legacy: Metals such as stainless steel, titanium or aluminum alloys offer superior durability, scratch resistance and longevity. Your custom metal chess piece will become a family heirloom that will last for many years to come.

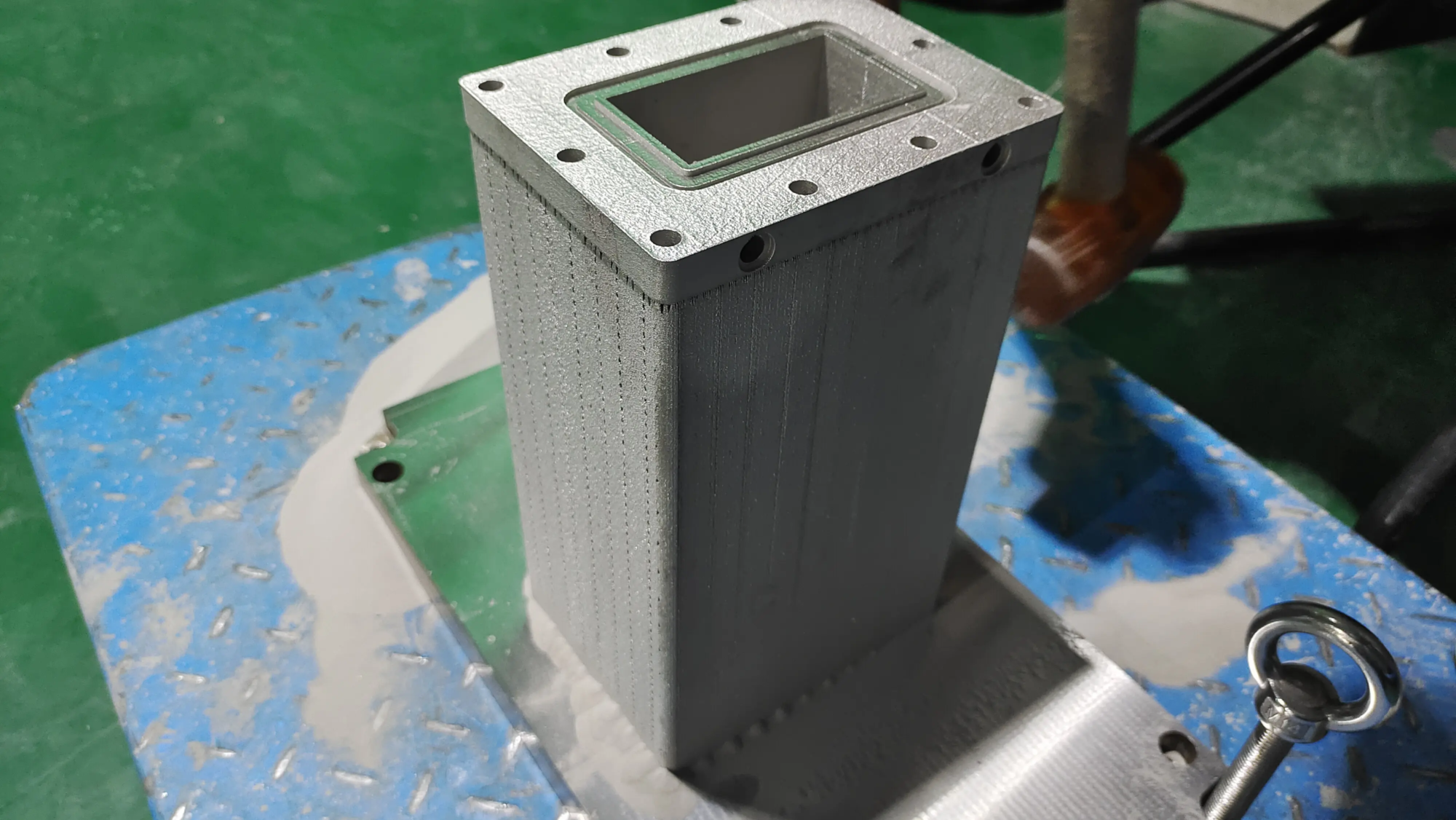

- Exquisite details and finishes: Utilize advanced technologies such as Selective Laser Melting (SLM)GreatLight achieves incredible accuracy, capturing intricate details on even the smallest chess pieces. Crucially, their Comprehensive one-stop post-processing services – including precision machining, fine polishing (mirror, satin, sandblasted), electroplating and specialty coatings – to transform printed metal chess pieces into exquisite, professional-grade parts that are indistinguishable from traditionally manufactured parts. This ensures perfect aesthetic integration and a superior tactile experience.

- Customized accuracy: Need pieces with a slightly larger base for a specific board? Need a unique metallic finish? GreatLight leverages its SLM capabilities and finishing expertise to deliver Customized precision machining Made exactly to your specifications, guaranteed to fit perfectly into the suit you envisioned.

Why start with pawning?

Pawn is the perfect entry point for custom 3D printed chess sets:

- volume: There are 16 pieces in a set! Replacing or customizing them can provide maximum visual impact.

- Simplicity (relative): While complex designs are possible, the geometry of chess pieces is generally less complex than that of a knight or queen, making them faster and cheaper to prototype and print, and particularly suitable for testing metals and finishes.

- experiment: Pawn allows you to try out different designs, materials (via GreatLight), and finishes before committing to a full set.

Material selection: from table to display stand

- Home Printing (FDM/Resin): Great for colorful themed prototypes or plastic replacement parts. Offers accessibility and speed, but lacks the weight and durability of metal.

- Professional metal printing (e.g. GreatLight): Create a truly high quality, durable and unique chess piece. SLM produces solid metal parts that transform the gaming experience. Materials include:

- Stainless steel (316L): Classic, sturdy, versatile and suitable for plating/polishing.

- titanium: Lightweight yet very sturdy, hypoallergenic and unique looking.

- Aluminum alloy: Light weight, excellent thermal conductivity, and good surface finish.

- Copper/Bronze Alloys: Unique warm tint (usually by electroplating).

- GreatLight’s expertise ensures the best material selection and processing for your specific pawn design and functional requirements.

Designing Pawn for 3D Printing Success

Cooperation with experts is key, especially for metals:

- Balance and Stability: Center of gravity is crucial. Design software simulations can help, but real-world prototyping with a partner like GreatLight ensures perfect stability after printing and finishing. Slightly weighted bases are often integrated.

- Strength and geometry: Minimize fragile flakes. SLM handles complex shapes well, but optimizing orientation and support minimizes material waste and post-processing time, which is where GreatLight process optimization comes into its own.

- Base diameter: Precise measurements that match the board’s squares are critical to getting professional results. Custom machining during post-processing ensures a perfect micron fit.

- Surface finish: Specify the desired aesthetic early on—polished sheen, textured grips, enamel color? GreatLight’s extensive range of post-processing capabilities transform original prints into masterpieces.

Conclusion: Your Board, Your Rules

"printing pawn" It’s not just about creating game pieces; it’s about making your chess experience personally meaningful and of unparalleled quality. 3D printing democratizes customization, allowing everyone from hobbyists to professional set designers to bring unique visions to life. Home printers open the door to discovery, while metal 3D printing elevates pawns (and entire sets of pawns) into long-lasting, functional works of art.

For those looking for truly exceptional, durable and precisely customized metal chess pieces – especially ones that redefine perception – with Professional rapid prototyping manufacturer is essential. huge lightwith its advanced SLM metal printing technology and comprehensive One-stop post-processing and finishing servicesis the primary solution. their expertise Customized precision machining Be sure to not only have visually striking chess pieces, but also ensure that the chess pieces are designed to have perfect balance, perfect fit, and a traditional feel. Take your game board from ordinary to extraordinary. Explore the potential of print pawns today.

Frequently Asked Questions about Printing Pawns

-

Question: Why focus on chess pieces?

A: Pawn offers the highest volume per set and significant visual impact. They are generally easier to design/make than complex knights or queens, making them an ideal starting point for customization and prototyping.

-

Q: Can I actually recreate a lost piece exactly?

Answer: Yes! Using precise caliper measurements and photos (or ideally, 3D scans) of the remaining pawn, a skilled professional can create a near-perfect digital model and replicate it through 3D printing, matching materials and finishes as closely as possible (this works especially well for metals and GreatLight’s surfacing services).

-

Q: Are 3D printed chess pieces strong enough for everyday use?

one: Materials and workmanship are very important. Resins and PLA can be brittle; high quality SLA/SLS resins or industrial printed thermoplastics are more suitable plastics. Metal chess pieces printed by SLM (like the ones from GreatLight) are extremely durable and ideal for heirloom quality sets.

-

Q: How expensive are custom metal 3D printed chess pieces?

A: Cost depends on metal type (titanium > stainless steel > aluminum), design complexity, pawn size, quantity and finish level. While each piece is more expensive than mass-produced plastic, they have unique artistic value and durability. GreatLight focuses on delivering high-value rapid prototyping solutions at competitive pricesespecially valuable for custom designs that don’t require expensive molds.

-

Q: What materials are most suitable for creating a high-end feel?

one: Metal is ideal. Stainless steel (316L) offers classic weight and polished properties. Titanium is extremely strong, lightweight and has a unique look. Aluminum alloy is lightweight and has a good surface finish. Brass/bronze (often achieved by electroplating) provides a warm aesthetic. Copper has unique properties. GreatLight can advise you on the best materials to suit your desired look and budget.

-

Q: Can I design my own chess piece shape?

Answer: Of course! This is the core benefit. Use CAD software (beginner: TinkerCAD; intermediate: Fusion 360) or commission a designer. Make sure the design considers printability (support, drape) and functionality (balance, size). Working with GreatLight early ensures manufacturability.

-

Q: How long does it take to get a custom metal pawn?

A: Rapid prototyping significantly reduces lead times compared to traditional tools. Simple designs may be completed in a few days, while complex creations with intricate finishes may take weeks. GreatLight focuses on solving rapid prototyping challenges quicklyefficiently turn around high-quality metal parts.

- Q: Do I need special software?

A: Design, yes – CAD software. Print at home, slicing software. For professional metal printing like GreatLight, clean, manufacturable design files (STP, STL) compatible with their SLM are provided