Release tissue with custom nail hooks: Your complete DIY guide

Nail hooks look like modest hardware, but they are the unsung heroes of the organization – from garages rich in tools to minimalist kitchen walls holding cookware. Standard hooks are usually insufficient: too weak, too rigid, or just not quite Suitable. That’s where 3D printing Change the game and transform customization from luxury to accessible reality. With this DIY guide you will learn design, print and perfect tailor-made nail hooks your Space – It’s time to upgrade, how Greglight’s industrial-grade 3D printing service Provides power and precision when a hobby printer cannot.

Why 3D printing custom nail hooks?

- Perfect for: Match the unique curves, depth and load requirements of the gear.

- Strength on demand: Choose professional metal printing for heavy-duty tools or machinery.

- Cost Efficiency: Avoid large orders with universal hooks; print exactly what you need.

- Intelligent design freedom: Integrates anti-sliding grooves, keyhole mounts or brand aesthetics and other functions.

DIY Guide: From CAD Model to Completed Hooks

Step 1: Design the nail hook

tool: Start with free software Tinkercad (Beginners) or Fusion 360 (Advanced).

Key design tips:

- Load Analysis: If holding > 1kg, thicken the wall/base. Use ribs to reinforce the metal design.

- Installation Mechanics: Design flanges for screws, magnetic bases or nail plates on the back.

- Ergonomics: The shape hooks to the cradle item (for example, the flared end of the guitar neck).

👷 hint: Greglight offer Free design consultation. Stuck at the pressure point or CAD? Their engineers optimize files for printability and durability.

Step 2: Material Selection – Matching Function and Manufacturing

| Use Cases | DIY Materials (FDM) | Professional Materials (Greglight) |

|---|---|---|

| Light decoration | PLA | Polished stainless steel |

| Outdoor/Durable | Petg | Anodized aluminum |

| Heavy Industry | Nylon (Limited) | Titanium alloy |

| Flexible requirements | TPU | – |

Why metal? For hooks fixed > 5kg or exposed to heat/chemicals, SLM (Selective Laser Melting) Metal printing with Greatlight ensures zero deformation, corrosion resistance and machining-level accuracy.

Step 3: Printing Technology

For home FDM printers:

- direction: Print hooks upright for structural integrity (minimize layer line stress).

- set up: 50–100% fill, 0.15mm layer height and fiber adhesion.

- Time/success trade-offs: PETG bonds to the layer at a balanced speed of 40mm/s.

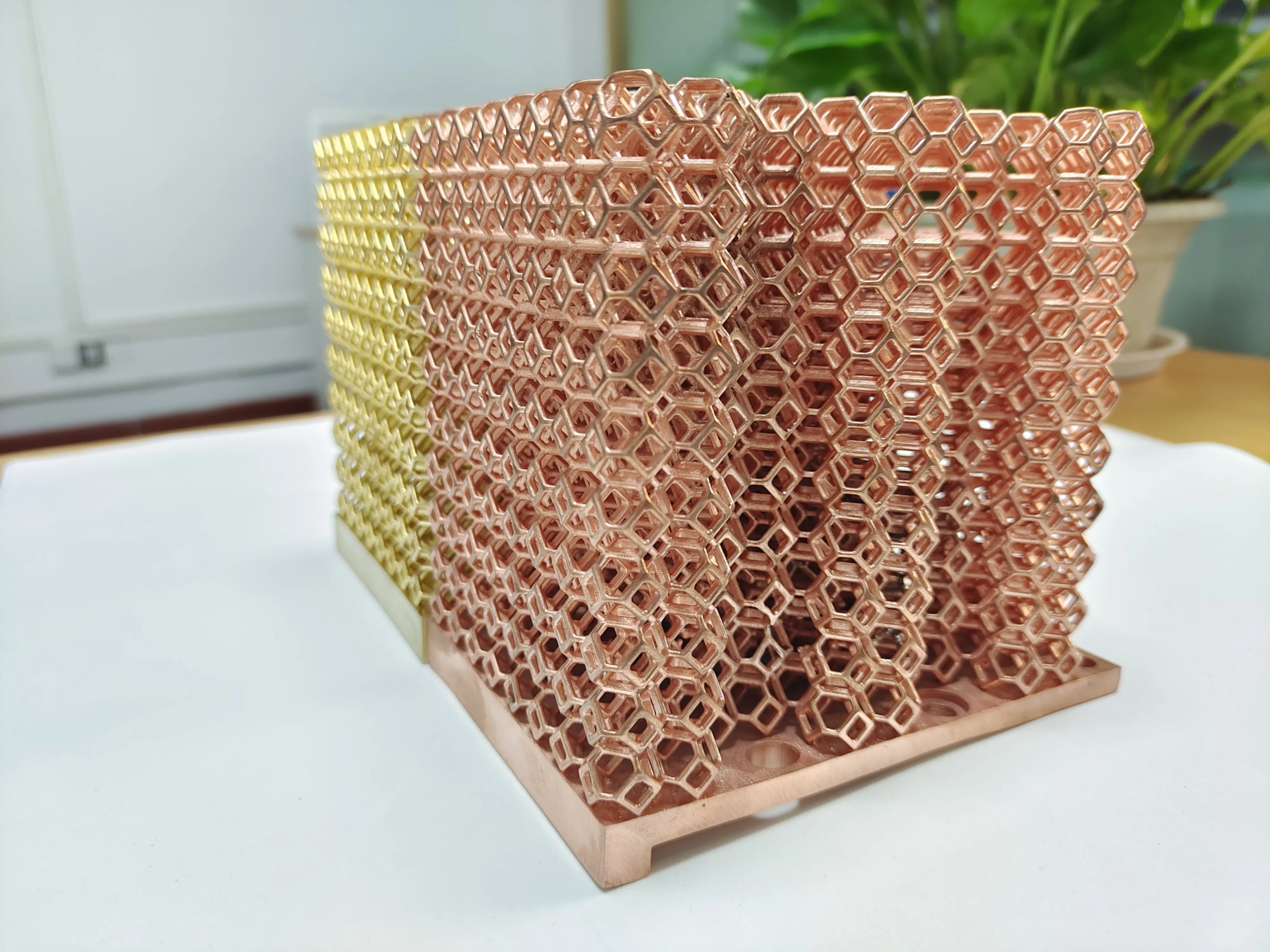

Professional metal printing: Great SLM printer Use laser to build hooks and fuse metal powder (aluminum, steel, etc.). result? Completely dense, affordable parts with tolerance of ±0.1mm for critical applications such as automotive or aerospace tools.

Step 4: Post-processing and completion

DIY:

- Sand with 120→400 grain size, original and spray paint.

- Coat PLA with epoxy for UV/waterproofing.

Professional finishing (Greglight’s Edge):

- polishing: Retail display mirror finish.

- Smooth paint: Powder coating or electropolishing.

- Functional therapy: Heat treatment or anodizing color code for heated steel.

Conclusion: Custom hooks, uncompromising quality

3D printing will democratize customization, but materials science is important. For hook requirements Lifetime reliabilityGreglight Bridges DIY wishes and industrial rigor. Their SLM technology and CNC-POST processing process what consumer printers can’t do: aerospace alloys, FDA-friendly kitchen metals or mass batch processing consistency.

🚀 Are you ready to print better? access Greglight’s platform Used for instant quotes on custom metal/plastic hooks. Upload your CAD, select the finish and ship it around the world.

FAQ: Custom nail hooks

Q: Can 3D printed hooks hold weight?

one: Yes-Have the right materials and design. 2–5kg of PETG or nylon handles in FDM prints; Greglight’s metal hook (Steel/Aluminum) supports 20kg+. Submit your specifications for load testing verification.

Q: How thin are metal printed hook walls?

one: Just as thin 0.4mm SLM printer with Greatlight. We will analyze the liquid dynamics for powder resurfacing during the design review process.

Q: Which file format do you accept?

one: We handle steps, STL, OBJ and IGES. Need a format conversion? Our team optimizes geometric integrity.

Q: How fast is the metal nail hook produced?

one: As fast as possible 3-5 working days For most orders. Rush service is available. Post-treatment is increased by 1-2 days, such as gold plating, etc.

Q: Why choose Greatlight instead of DIY print hook?

one: When failure is not an option – think about it Garage hoist, medical equipment hook or outdoor device– Our certified materials, pressure simulation and industrial post-processing ensure safety compliance and lifespan far exceeds hobby-grade output.

Your space, rules. Whether it’s the idea of making prototypes at home or scaling a rough hook for the industry, 3D printing can be reshaped. With Greatlight, even the most complex nail hooks become a reality for plugins – precisely designed for competitive prices. ⛓️ Design. Print. organize.