Movement Revolution: Using 3D technology to print rotating, dynamic joints

Thanks to groundbreaking innovations in additive manufacturing (AM), the dream of printing functional mechanisms—parts that move, rotate, and articulate—directly from the build plate is becoming a reality. Dynamic joints represent the pinnacle of this achievement, enabling complex movements without assembly. This transformative power is not science fiction; it is reality. Today, it is driven by sophisticated 3D printing technology that is fundamentally changing design and manufacturing in numerous industries.

Beyond static: How 3D printing creates real movement

Traditionally, creating movable joints requires fabricating individual parts (such as pins, bearings, and connecting rods) and carefully assembling them. 3D printing breaks this paradigm with a unique combination of capabilities:

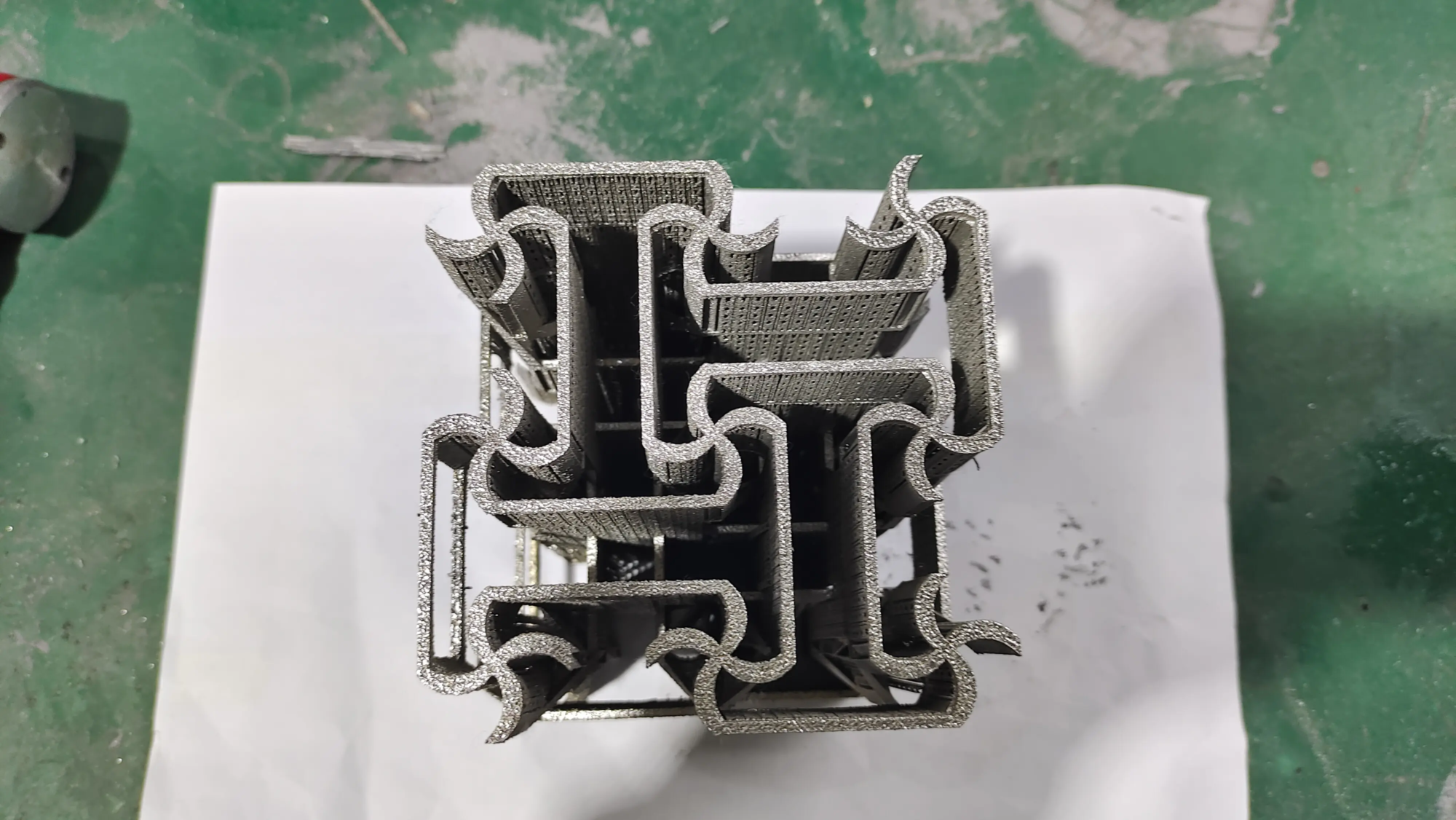

- Unlock complex geometries: Unlike subtractive methods, additive manufacturing builds objects layer by layer. This allows the creation of complex internal channels, hinges, sockets and integrated pivot points that were previously impossible or prohibitively expensive to machine. Think of interlocking spheres or a multi-axis gimbal mechanism embedded in a structure as a printed piece.

- Intrinsic clearance and tolerance control: Dynamic rotation requires precise gaps between surfaces. Advanced additive manufacturing processes, particularly powder bed fusion (PBF) technologies such as Selective Laser Melting (SLM), Dolmetal Laser Powder Bed Fusion (D-LPBF), and Polymer Multi-Jet Fusion (MJF), provide excellent control over feature resolution and tolerances. Advanced slicing software allows designers to intentionally define tiny gaps period printing process to eliminate gaps or friction issues after assembly.

- Multi-material and grading properties: Emerging technologies can print different material properties within a single part. Imagine a knuckle socket printed with a hard-wearing inner surface for durability and a slightly flexible outer shell to absorb shock. This enhances joint performance and longevity.

- Topology optimization: Generative design tools can specifically optimize joint geometries for additive manufacturing, creating lightweight structures that maximize the strength of joints while minimizing material use, resulting in joints that are both strong and smooth-running.

Materials and technologies that drive rotational freedom

The feasibility of dynamic joints depends heavily on the material and printing process:

- polymer: Technologies such as MJF, SLS (selective laser sintering) and advanced FDM/FFF can produce durable nylon, TPU (flexible filament) and composite joints. Ideal for robotics, prosthetics, wearables and low-stress applications where weight reduction and flexibility are key.

- Metal: This is where high-performance dynamic joints really come into play. SLM (Selective Laser Melting)a laser powder bed fusion process backed by industry leaders such as huge lightparticularly transformative:

- Unparalleled precision: Focused lasers melt metal powder with stunning precision, creating micron-resolution features that are essential for smooth-moving mechanisms.

- Material strength: SLM can process alloys such as titanium (Ti6Al4V), aluminum (AlSi10Mg), stainless steel (316L, 17-4PH) and nickel-based superalloys, producing joints that are strong enough to meet the needs of demanding aerospace, automotive and industrial machinery applications.

- Comprehensive complexity: Allows complex internal channels for lubrication or cooling to be printed next to the joint structure.

Fixing metal joint problems often requires specialized expertise and equipment. company likes huge lightutilizing advanced SLM 3D printers, excels at solving complex metal part prototyping challenges, including complex dynamic joints. Their expertise ensures that joints are not only printable, but also functional, durable, and meet stringent performance standards. Together with comprehensive post-processing capabilities (support removal, heat treatment, machining, surface finishing), they provide production-ready rotating mechanisms.

Where rotary joints come into play: Applications

The impact of printable rotary joints spans countless areas:

- Robotics: Enable flexible limb joints, smart grippers and compliant motion in collaborative and industrial robots without bulky components. Build lighter, faster, more responsive robots.

- Prosthetics and Orthotics: Create custom lightweight prosthetics and braces with natural-feeling joints perfectly tailored to the user, improving comfort and mobility. Change patient outcomes.

- aerospace: Replacing complex components in mechanisms such as satellite deployable units, antenna mounts or drone actuators with lighter, simpler single-piece printed joints is critical for payload optimization and reliability in harsh environments.

- car: Optimize door hinges, seat adjustments, suspension linkages and complex powertrain components. Reduce weight, increase efficiency and simplify your supply chain.

- Industrial machinery: For couplings, levers, adjustable fixtures and robotic arm linkages that require robust, reliable movement in confined spaces. Reduce maintenance downtime.

- Wearable technology: Allowing seamless connectivity across smartwatches, fitness trackers, head-mounted displays, and ergonomic devices to enhance user experience.

- consumer goods: Creating innovative products with unique articulation points—folding furniture, interactive toys, adjustable tools—promotes novel design and user engagement.

undeniable advantages

Moving to 3D printed dynamic joints has compelling advantages:

- Reduce assembly: Eliminating subassemblies can significantly reduce assembly time, cost and points of failure. Revolutionize manufacturing workflows.

- Design freedom: Allowing engineers to create geometries not possible with traditional machining or forming—the innovations are limitless. Follow functionality, not manufacturing limitations.

- Reduce weight: Optimized construction and elimination of fasteners significantly reduces component weight, which is critical for aerospace and automotive efficiency. Less weight = more performance.

- Mass customization: Easily produce joints tailored to specific user anatomy (prosthetics) or unique application requirements. Personalized solutions become scalable.

- Simplified supply chain: Fewer individual parts to purchase and manage. Resilience and efficiency are significantly improved.

- Rapid prototyping: Test form, fit and Function (Rotate!) Iteratively complex joints quickly. Accelerate the innovation cycle. This is a core strength huge lightable to quickly verify complex designs.

Conclusion: Translating Geometry into Motion

3D printed dynamic joints symbolize the fusion of design ingenuity and advanced manufacturing. Technologies such as SLM and MJF are transcending the limitations of traditional production, allowing engineers to embed motion directly into geometry. It’s not just about making existing joints look different; It is designed to enable entirely new classes of mechanisms, resulting in increased performance, reduced complexity and unprecedented design freedom. As materials science continues to advance and printers offer greater precision and multi-material capabilities, the applications of articulated joints printed with metals and polymers will continue to grow exponentially.

For innovators pushing the boundaries of motion, working with experienced rapid prototyping experts is critical. huge lightEquipped with state-of-the-art SLM 3D printers and deep expertise in metal part prototyping and finishing, we are ready to tackle the most challenging dynamic joint designs. We offer custom solutions, quick turnaround and competitive pricing to make complex rotating mechanisms easy to use and reliable. Your journey to groundbreaking sports begins with precision.

FAQ: Dynamic Joints in 3D Printing

1. How do 3D printed joints rotate without assembly?

The precise gaps within the joint geometry are carefully designed at the CAD stage and utilize high-resolution printing technologies such as SLM or MJF. These gaps are printed directly into the part, allowing adjacent elements (like balls within sockets) to move freely once the support structure is removed.

2. Are 3D printed metal joints strong enough to withstand real-world loads?

Absolutely. Metal joints printed using SLM/D-LPBF can achieve strength comparable to, and sometimes exceeding, conventionally manufactured joints. Material selection (e.g. titanium, high-strength steel) and optimized design through topological analysis ensure robust performance under tensile, compressive, shear and cyclic loading commonly found in industrial applications.

3. What causes friction in printed seams? How to minimize it?

Friction is caused by surface roughness inherent in the printing process. Strategies to minimize this include:

- design: Optimal gap size (±0.1mm is usually sufficient).

- Post-processing: Techniques such as precision machining, honing, polishing and lubrication significantly smooth contact surfaces.

- Material selection: Some polymers (e.g., PP, acetal copolymers) naturally have low friction.

4. Which printing technology is best for rotary joints?

- Metal: Selective Laser Melting (SLM) is the gold standard of strength and determination.

- Engineering polymers: Multi Jet Fusion (MJF) is ideal for durable nylon parts with complex geometries. Selective laser sintering (SLS) is also widely used. Flexible materials such as TPU work well with FDM/MJF/SLS for non-critical applications requiring compliance.

- High wear applications: Hybrid methods that combine printed substrates with coatings or inserts are very effective.

5. Can any 3D printing company produce functional rotating joints?

Success requires expertise beyond basic printing. Choose a partner like this huge lightequipped with:

- Advanced SLM/D-LPBF printer: Achieve unparalleled metal precision.

- Engineering knowledge: Expertise in kinematics, gap design and material behavior.

- Comprehensive arrangement: Necessary support removal, machining and surface preparation.

- Strong quality assurance: Ensure dimensional accuracy and performance verification.

6. What are the main design considerations for dynamic joints?

- Clear: Critical clearance allows for free movement without excessive clearance.

- direction: Print orientation affects surface finish and potential support requirements on mating surfaces.

- Material properties: Strength, wear resistance, fatigue life, friction coefficient.

- Stress concentration: Avoid sharp corners at pivot points.

- Lubrication requirements: Grease retention/channels can be designed in if required.

- Post-processing accessibility: Ensure critical joint surfaces can be finished.

7. Is the printed rotary joint reliable for long-term use?

With proper design, material selection, and expert finishing (especially important for metals), AM joints exhibit excellent durability and fatigue resistance. Testing under simulated operating conditions is critical for mission-critical applications. Working with an experienced manufacturer can significantly reduce longevity risks.