The Evolution of Glock Frame Prototyping: Metal 3D Printing Basics

The world of gun parts, especially frames like Glock pistols, lies at the fascinating intersection of precision engineering, strict regulations and ever-evolving manufacturing techniques. While CNC machining of forged or molded blanks has traditionally been the focus, additive manufacturing (AM), specifically metal 3D printing, is becoming a powerful tool for Prototyping, testing and low-volume production app. Understanding the basics of printing Glock frames, especially using advanced metal additive manufacturing technologies like Selective Laser Melting (SLM), is critical for engineers and developers to push the boundaries of firearms innovation within a regulatory compliance framework.

Why go beyond traditional prototyping with the Glock frame?

Traditional prototyping methods such as CNC machining provide excellent accuracy, but have significant limitations for complex frame geometries:

- Cost and delivery time: The complex internal voids, intricate undercuts and ergonomic contours common in frames often require multi-axis machining and complex setups. This adds time and cost to one-off prototypes or small batches.

- Design iteration bottlenecks: Modifying the frame geometry after initial CNC prototyping requires reprogramming tool paths and possibly refixing, significantly slowing down the design verification cycle.

- Material waste: Subtractive processes generate significant amounts of material waste, especially for complex shapes starting from blanks.

Metal 3D printing directly addresses these pain points by creating complex geometries layer by layer directly from digital models.

The shift to metals: why polymers are insufficient for functional testing

While hobby-grade FDM printing using polymers like PLA or nylon has made headlines Receiver applicationthese materials are basically not suitable for Functional prototyping and testing Glock Frame Designed to Withstand Live Fire Pressure:

- Material properties: The polymer lacks the necessary tensile strength, stiffness, creep resistance and ductility needed to safely manage repeated recoil forces.

- Thermal resistance: Barrel heat can quickly compromise polymer integrity near the locking block and chamber areas.

- Supervision and Responsibilities: Prototype frames for functional firearm assembly require materials with known metallurgical properties and traceable manufacturing processes, making metal additive manufacturing a specialized solution.

For rigorous functional testing, engineering evaluation and compliant low-volume production (where permitted by law), metal powders processed through techniques such as SLM can deliver the required performance characteristics.

Inside the Metal Printing Process: Selective Laser Melting (SLM)

SLM is a laser powder bed fusion (LPBF) technology particularly suitable for demanding applications such as firearm components. Here is the process:

- Digital Blueprint: The frame design was carefully modeled and optimized for additive manufacturing, taking into account the support structures required during the printing process. Considerations include orientation of minimum support points, maximizing stiffness vectors, and eliminating stress concentrations.

- Material preparation: Fine metal powder alloys – most common Stainless steel (e.g. 17-4PH or 316L for corrosion resistance) or maraging steel (such as Maraging 300, which has high strength after heat treatment), is loaded into the printer.

- Fusion layer by layer: A thin layer of powder is spread evenly over the build platform. A high-power laser scans the frame cross-section defined by the digital model, selectively melting and fusing the powder particles. The platform is lowered and the process repeated until the entire frame is built.

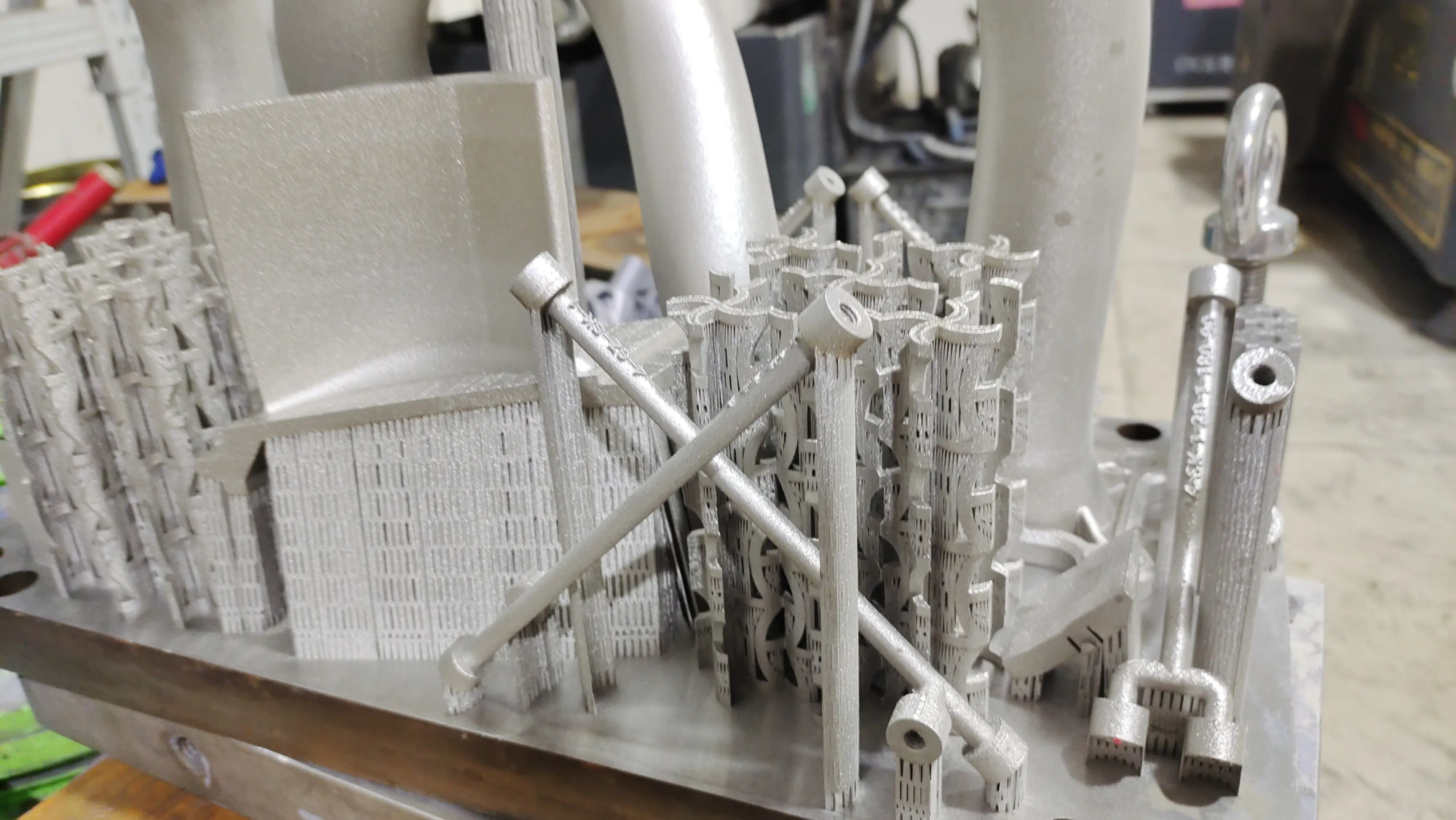

- Post-processing: The printed component, encapsulated in loose powder and attached to the build plate via brackets, undergoes:

- Remove powder: Carefully remove loose powder.

- Relieve stress: A critical heat treatment removes internal residual stresses caused by rapid thermal cycling during printing.

- Support removal: The supports have separated.

- Solution Aging/HIP: Maraging steel is solution treated and aged to achieve peak strength and toughness. Hot isostatic pressing (HIP) is often used to eliminate internal micropores.

- Precision machining: CNC machining of critical mating surfaces (rails, pin holes), potential surface treatments (nitriding, coatings) and rigorous quality inspection (dimensions, NDT).

Why metal SLM stands out in frame prototyping and production

- Standard complexity: Internal voids, lattice structures (for weight reduction studies), organic ergonomics – SLM excels in areas where processing is difficult.

- Strength and integrity: Correctly machined aerospace-grade metal matches additive manufacturing parameters with yield densities exceeding 99.9% and mechanical properties that rival or exceed forgings.

- Faster iteration: Design changes can be implemented simply by updating the CAD model, significantly speeding up the development cycle.

- Material efficiency: Compared to subtractive processes, near-net-shape production minimizes expensive alloy waste.

- Comprehensive features: Channels, cavities or custom mounting points can be integrated directly into the design without the need for secondary operations. Great for proof of concept setup.

Get through the critical design stages

Successful metal AM printing of the Glock frame relies heavily on Design for Additive Manufacturing (DfAM):

- direction: Support requirements, material anisotropy, surface finish and critical feature accuracy are specified. Typically, the rails may be oriented vertically.

- Support structure: Overhangs and internal cavities are required to prevent warping/collapse but add post-processing complexity. Designed to minimize support.

- Wall thickness: The minimum thickness requirements for the specific alloy/printer must be adhered to (typically >0.4 mm).

- Stress concentration: Rounded corners/gussets mitigate sharp corners prone to stress cracking under kickback load simulations.

- Tolerances and surfaces: Features that require high accuracy/flatness (rails, pin holes) are designed to be oversized for subsequent CNC machining.

Partner with expertise: When precision requires professional solutions

Bringing a digitally designed Glock frame prototype to life requires deep expertise, not just owning a printer:

- Materials Science: Select the best alloy and post-treatment options to improve strength/toughness/fatigue resistance.

- Process parameterization: Expert adjustments to laser power, speed, fill spacing, layer thickness and scanning strategy ensure the creation of dense, crack-free structures. This is highly material and geometry specific.

- Metallographic analysis: Microstructural verification (optical/SEM), pore analysis and mechanical testing (tensile, hardness) are critical to validate critical components.

- Regulatory awareness: Understand the legal environment governing firearms manufacturingincluding frame transfer and collation requirements, are critical. Reputable partners strictly adhere to ATF guidelines and provide services to prototyping/FFL07 authorized manufacturers.

- Post-integration processing: Seamless integration between printing and precision CNC machining/Videojet finishing is critical for consistent rail engagement, pin fit and QA standards.

This is where professional rapid prototyping manufacturers, e.g. huge light Become a valuable partner. Utilizing advanced SLM equipment and production technology, coupled with deep metallurgical and machining expertise, huge light Expertise in solving complex rapid prototyping challenges of demanding metal parts, including firearm frames. Providing a fully integrated one-stop shop – from certified material selection and DfAM optimization to precision machining, heat treatment, finishing (nitriding, coating) and comprehensive QA/NDT – huge light Eliminates the typical debris associated with procurement prototype manufacturing. For custom precision prototyping where material properties and dimensional accuracy cannot be compromised, work with an experienced supplier such as huge light Ensure a path from proven concept to functional hardware.

in conclusion

Printing the Glock frame through advanced metal additive manufacturing techniques such as selective laser melting represents a major leap forward in engineering prototyping and controlled production environments. SLM offers compelling advantages over traditional subtractive methods by enabling unparalleled geometric freedom, reducing lead times for complex iterations, and utilizing materials that meet stringent functional requirements. However, success depends on adopting additive manufacturing design principles, leveraging deep metallurgical and process expertise, and working with qualified suppliers with strict quality control systems and regulatory awareness. For innovators pushing the boundaries of firearm component design within a regulatory compliance framework, metal additive manufacturing prototyping provides a powerful, efficient path from digital concept to robust physical reality, laying the foundation for future innovation where permitted by law and carefully enforced.

FAQ: Printing Glock Frames – Metal Additive Manufacturing

Q: Is it legal to print a Glock frame at home?

one: Federal law (US) defines the receiver/frame as the firearm itself. A manufacturer’s license (Type FFL 07) is required to manufacture firearm frames. Personally manufactured for personal use No intention to sell,possible Has federal legality under certain conditions (Check ATF regulations! ), but State/local laws often impose stricter prohibitions. Professional use of metal additive manufacturing is typically limited to prototyping under license by licensed manufacturers for research and development or low-volume production.

Q: Can I use regular plastic FDM printers?

one: Although physically feasible, polymer frames printed via FDM/FFF Highly Discouraged and Potentially Dangerous For use in functional firearms. Standard filaments lack the mechanical strength, thermal stability and durability needed to safely contain the stress and heat generated by live ammunition. Plastic frames are only suitable for non-shooting models, props or training aids.

Q: What metal alloys are commonly used for printing frames?

one: Stainless steel (such as 17-4PH H900/A1100 or 316L) has good strength and corrosion resistance. Maraging steels such as Maraging 300 are particularly popular due to the ultra-high strength-to-weight ratio achieved after aging heat treatment. The choice depends on the prototype requirements (strength, toughness, corrosion resistance). Less common options include titanium alloys.

Q: Does the printed metal frame need to be processed?

Answer: Of course. Key functional interfaces such as slide rails, lock block surfaces, pin holes (trigger/slide lock/lock block) and front/rear rail modules must Precise CNC machining after printing to achieve necessary tolerances (flatness, parallelism, hole size/position). Surface finishing (milling, grinding, potential coating) is also crucial. Printing + machines are essential.

Q: How strong is a metal printed frame compared to a forged or milled frame?

one: When machined correctly using optimized SLM parameters and appropriate heat treatments (solution annealing + aging for maraging steels, stress relief for stainless steels), SLM-produced frames can achieve tensile strength, yield strength and hardness that are comparable to or even exceed those of conventional forged/milled frames. Fatigue performance requires careful DfAM and process control.

Q: What is the biggest challenge in printing a reliable Glock frame?

one: Key challenges include:

- Manage stress concentrations caused by backlash through design (supporting avoidance near high stress areas).

- Prevent warping/shrinkage during printing through orientation/support strategies.

- Eliminate internal porosity or inclusions through strict process control and potential HIP treatment.

- Achieve precise dimensional accuracy on critical rail/pin holes that require secondary machining (CNC machining).

- Navigate a complex regulatory environment safely and legally.

Q: Why choose a service like GreatLight instead of doing it yourself?

one: Successfully producing fully functional, reliable, and compliant metal printed frames requires hundreds of thousands of dollars worth of specialized equipment, deep expertise in metallurgy, DfAM, SLM process parameterization, heat treatment regimes, precision CNC machining, rigorous QA procedures, and a rigorous understanding of regulatory compliance. huge light As your expert partner, we provide turnkey solutions to manage entire complex workflows, ensuring high-quality results efficiently and professionally, allowing you to focus on designing innovation rather than creating obstacles.