Introduction: The Garbage Technology Revolution

The global waste crisis is at a turning point. Landfills are swelling, oceans are choking on plastic, and resources are dwindling. At the same time, advanced manufacturing seeks sustainable solutions. At this crossroads, a transformative innovation emerged: Waste to Print (W2P) technology. This concept reimagines discarded materials (plastic bottles, scrap metal, construction waste) into feedstock for industrial-grade 3D printing. By transforming waste into functional components, W2P provides a blueprint for a circular economy. As pioneers in precision manufacturing, we huge light Recognizing the synergy between sustainability and cutting-edge production. Our expertise Selective Laser Melting (SLM) 3D Printing Putting us at the forefront of integrating recycled materials into high-performance applications. Let’s explore how "3D trash can technology" Manufacturing is being reshaped.

The science of turning waste into treasure

-

Collection and classification:

Classify waste streams (domestic, industrial or marine) using AI-driven systems and spectroscopy. Plastics are separated by polymer type (PET, ABS, HDPE), while metals such as aluminum, steel or titanium alloys are separated by magnetism or density. -

Processing and purification:

- plastic: Chopped into thin slices, washed and chemically treated to remove contaminants.

- Metal: Smelted or atomized into fine, uniform powder. Critical to SLM printing, metal particles must meet strict size/sphericity standards (typically 15-45 microns).

Innovative methods such as pyrolysis break down complex waste, such as tires, into reusable carbon black or oil.

-

material transformation:

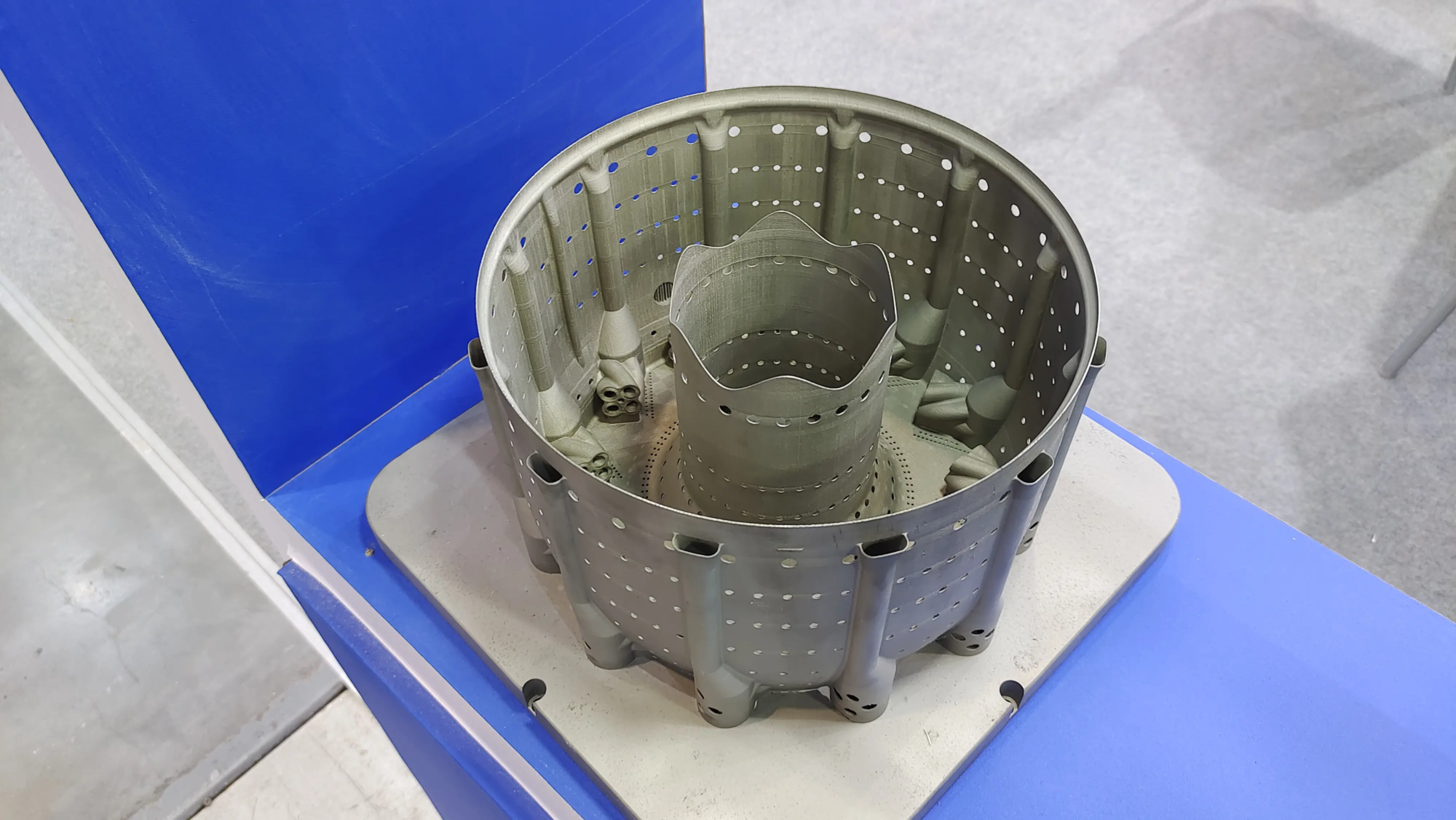

Plastic sheets are extruded into consistent 1.75mm/2.85mm filaments. Metal powders are alloyed for optimum sintering. GreatLight uses advanced SLM printers to fuse these powders layer by layer with high-power lasers to achieve complex geometries not possible with traditional machining. - Post-processing:

Parts are stress-relief annealed, CNC machined, surface polished or coated. Juguang one-stop shop Post-processing services Ensure recycled parts meet aerospace, medical or automotive specifications and debunk the myth that recycled materials are inferior.

Materials: What litter works best?

- plastic: PET (bottle), ABS (electronic waste), nylon (fishing net).

- Metal: Stainless steel (scrap metal), titanium (aerospace scrap), aluminum (cans).

Exclusions: Composite materials or heavily contaminated wastes remain challenging due to the complexity of purification.

environmental and economic impacts

- Resource saving: Mining virgin titanium emits 30 times more carbon dioxide than recycling scrap.

- waste diversion: 1 ton of recycled plastic can save 5.8 barrels of oil.

- Cost effective: Recycling metal powder can reduce material costs by 15-40%.

- circular economy: Products designed for disassembly can be reprinted an unlimited number of times, minimizing waste.

Challenges and innovations

pollute: Non-recyclable additives (such as PVC in plastics) can affect print quality. Solution: Artificial Intelligence Sorting Machine with Hyperspectral Imaging.

Material consistency: Uneven recycled powder can cause porosity in SLM parts. Solution: Advanced screening and plasma spheroidization.

Scalability: Industrial W2P requires a lot of energy. Innovation: Solar energy recycling microfactory.

GreatLight addresses these issues through R&D collaboration and adaptive SLM parameter tuning for different material batches.

Looking ahead: Beyond prototyping

W2P goes beyond rapid prototyping. Amsterdam has started 3D printing bridges from recycled plastic, while companies like CNC Machines are making furniture from ocean plastic. For metals, NASA explores recycling powder rocket parts. As recycling technologies advance, bioplastics and e-waste metallurgy will expand the material pool. Regulatory drivers, such as the EU Circular Economy Directive, will accelerate adoption.

Conclusion: Sustainable manufacturing is here

Printing from waste is not science fiction, but a scalable solution that blends ecological responsibility with engineering excellence. By converting waste into strong, precision parts, industries can reduce their environmental footprint without sacrificing performance. At GreatLight, we are committed to realizing this vision. our SLM 3D printing capabilitiesplus full spectrum Post-processing capabilitiesensuring recycled materials meet the tightest tolerances. Whether prototyping with recycled titanium or mass-producing marine-grade components from recycled plastic, we offer End-to-end solution Fast, affordable and good for the planet. Join us in redefining waste. Let’s use yesterday’s trash to build tomorrow.

FAQ

1. Can recycled materials be as strong as virgin materials?

Yes, with proper processing. GreatLight’s SLM printers can achieve recycled metal part densities of 98–99.5%, comparable to conventional alloys. Post-processing (HIP treatment, machining) further enhances mechanical properties.

2. Is W2P cost-effective for small batch production?

Absolutely. Unlike injection molding (which has high setup costs), 3D printing excels in low-volume production. Recycled materials reduce raw material costs, making them ideal for custom prototypes, spare parts or limited editions.

3. What metals can GreatLight print using recycled powder?

We specialize in SLM printing Stainless steel (316L), Titanium (Ti6Al4V), Aluminum (AlSi10Mg)and Inconel. If the recycled powder meets our strict quality specifications, we tailor the parameters for optimal results.

4. How "clean" Does waste plastic have to be used for printing?

Contaminants (food residues, non-recyclable polymers) must be minimized. GreatLight works with pre-treatment facilities to ensure filament purity. We also test batches for thermal stability and tensile strength before production.

5. Can recycled and virgin materials be combined?

Yes. Hybrid printing (e.g., recycled plastic core with virgin polymer coating) takes advantage of sustainability without compromising surface finish or structural integrity. Customized ratios can be adjusted based on project needs.

6. Which industries benefit the most from W2P?

- car: Lightweight recycled metal stand.

- put up: Recycled plastic fixtures.

- medical: Sterilizable titanium implants from waste.

- consumer goods: Upcycled packaging transformed into product enclosures.

Are you ready to turn waste into treasure?

glow offer rapid prototyping and Customized production Using recycled materials – our in-house SLM fleet and finishing lab accelerates this process. Request a quote for your sustainable manufacturing project today.