Unlocking precision and speed: the power of 3D printed screw caps

Forget about fiddling with mismatched sizes or waiting weeks for a tool. The humble screw cap—a deceptively simple component that’s essential for sealing, securing, and assembling countless products—is undergoing a revolution, thanks to 3D printing technology. This is not just incremental improvement; It unlocks unprecedented levels of customization, speed, and performance for designers, engineers, and manufacturers alike. Mastering 3D printed screw caps means mastering faster iterations, complex geometries and powerful functionality previously unachievable with traditional methods.

Why screw caps are more important than you think

Screw caps are a workhorse everywhere. They secure hydraulic fittings, seal chemical containers, protect delicate electronics, assemble prototypes and ensure the pressure integrity of pneumatic systems. Failure is not an option. Ill-fitting lids can leak, compromise safety, waste resources, or cause assembly lines to stall. Traditionally, sourcing or manufacturing these parts has involved compromises:

- Limited out-of-the-box options: Standard sizes may not meet exact size or performance needs.

- Long delivery time: CNC machining, injection molding or extrusion molds take weeks.

- Expensive custom tools: Prototyping iterations became extremely expensive.

- Geometric constraints: Complex internal threads, integrated seals or lightweight mesh structures are difficult or impossible.

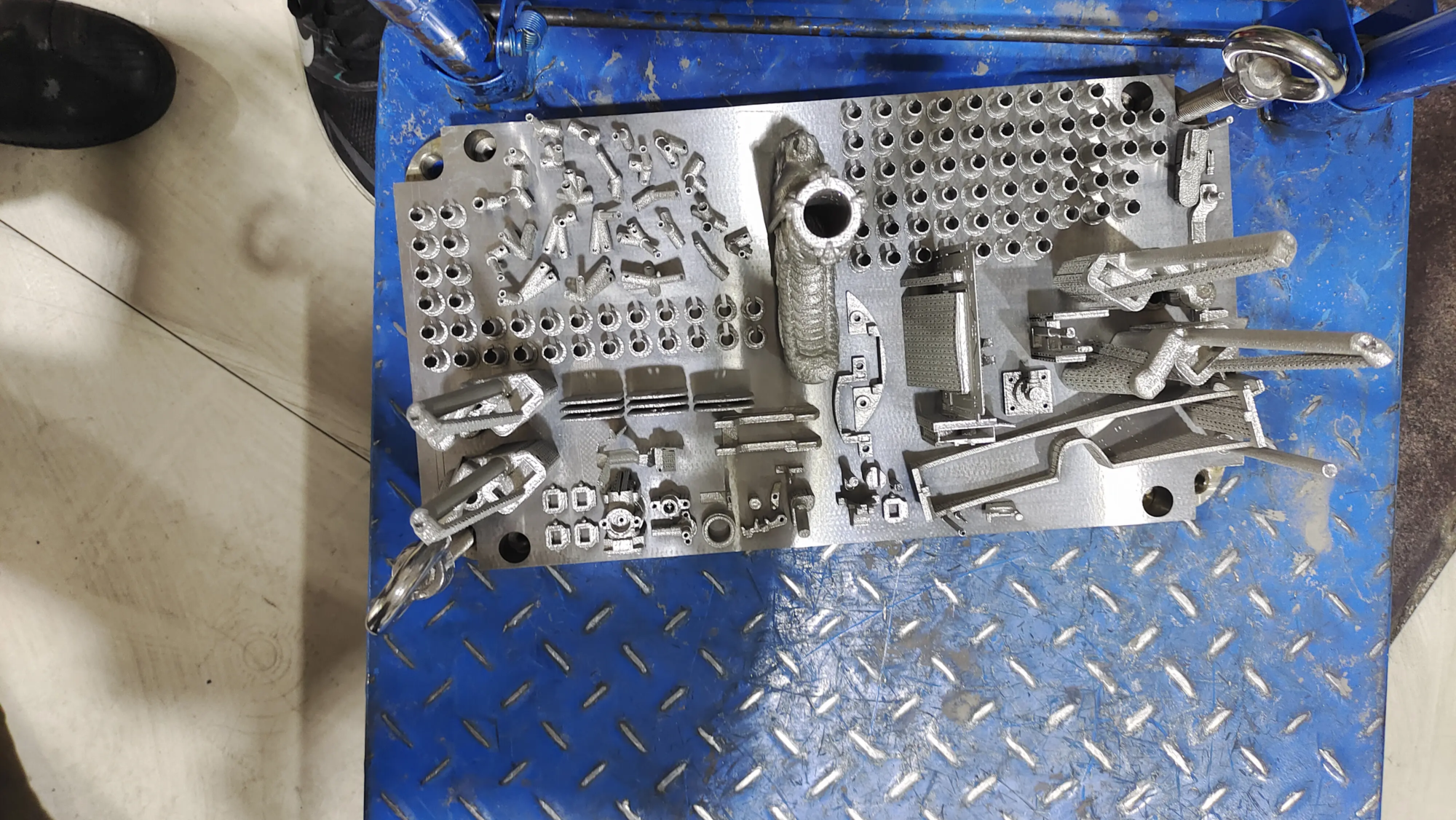

Enter 3D printing: reinventing the functionality of bottle caps

Additive Manufacturing (AM), specifically Selective Laser Melting (SLM) and Multi Jet Fusion (MJF), revolutionizing the way screw caps are produced. Here’s how:

-

Unparalleled design freedom: Imagine a hat:

- Precision internal thread: Complex thread profiles (metric, UN, Wyeth) can be printed directly with impeccable accuracy.

- Comprehensive features: The sealing O-ring is molded directly into the cavity within the lid that is printed as one piece. Seamlessly add flanges, knurls, tool interfaces and identification marks.

- Weight loss strategies: An internal lightweight mesh structure maintains strength while minimizing material use.

- Optimized shape: Custom ergonomic handles or non-standard sizes, precisely tailored to fit unique components. Design constraints disappear.

-

Record time from CAD to submission:

- Instant prototyping: Test endless design iterations—thread engagement, seal compression, torque resistance—in hours or daysnot weeks. Dramatically accelerate research and development.

- Agile small batch production: Need 5, 50 or 500 custom lids? 3D printing avoids tooling costs and delivers direct, making it ideal for low-volume runs, bridge production, legacy replacement or custom machinery.

-

Excellent materials for demanding tasks:

- Metal: SLM excels here, providing engineering-grade metals critical for strength, corrosion resistance, heat resistance and hermetic sealing:

- Stainless steel (316L, 17-4 PH): It has superior corrosion resistance and good strength, and is widely used in chemical industry, food processing, shipbuilding and other fields.

- Aluminum alloy (AlSi10Mg, aluminide): Light weight, good thermal conductivity, and excellent strength-to-weight ratio (aerospace, automotive, drones).

- Titanium (Ti64): Ultimate strength to weight ratio, biocompatibility, superior corrosion resistance (medical implants, aerospace).

- Inconel (718, 625): Extremely high heat resistance and oxidation resistance, high performance in aerospace and energy fields.

- polymer: MJF or SLS offers robust plastics such as nylon PA11/12 (flexible, chemically resistant) or specialty resins for less demanding environments.

- Metal: SLM excels here, providing engineering-grade metals critical for strength, corrosion resistance, heat resistance and hermetic sealing:

- End-to-end quality and precision (core focus of Ferrite):

Getting reliable screw caps requires more than just printing. exist huge lightour mastery comes from integrating the entire process:

- Precision CAD and DFAM: Expert design optimization for additive manufacturing ensures manufacturability and minimizes support structures.

- Industrial SLM system: Utilizing a calibrated state-of-the-art SLM printer, dimensional accuracy (±0.05 mm – ±0.1 mm) and material integrity are guaranteed throughout the part, especially important for threaded fits.

- Purposeful post-processing:

- Key thread finishing: Precision CNC post-machining ensures perfect thread shape, pitch and surface finish for reliable sealing and joining.

- Heat treatment: Increase strength (aluminum/steel aging) or relieve residual stress (stress relief annealing).

- Surface enhancement:

- Media Blasting/Shot Peening: Refines surface texture and improves fatigue life.

- Vibration Polishing/Tumble Polishing: Achieve smooth surface (optional aesthetics/internal cleanliness).

- Chem Film/Alodine (Aluminum): Temporary corrosion protection.

- Key sealing surface processing: Ensure flatness/parallelism where the O-ring is located.

- Non-destructive testing: Dye penetrant testing for critical sealing applications to ensure non-porous surfaces.

- Meticulous quality assurance: Advanced CMM metrology verifies critical dimensions, shape and thread geometry against CAD models. Torque testing verifies functional performance.

Highlights of 3D printed screw caps:

- aerospace: Lightweight vent/drain covers, sensor housings, non-standard hydraulic accessories.

- Medical devices: Sterilizable biocompatible implant/drainage cap, surgical tool housing.

- Automobiles and Motorsport: Custom reservoir caps, turbocharger accessories, sensor ports, prototype components.

- Industrial machinery: Custom hydraulic ports, gauge adapters, used service parts for discontinued equipment.

- consumer goods: Prototype housing, ergonomic cap, special tool accessories.

- Electronic products: Custom sensor housing requiring IP-rated sealing.

Case Study: Embracing Mastery at GreatLight

As a leading professional rapid prototyping manufacturer, huge light Leverage advanced SLM technology to solve everyday complex metal parts challenges. We know that a screw cap is more than just a cap; This is a critical interface point. Our expertise goes beyond printing – we offer Complete one-stop solution include:

- Prototyping: Iterate quickly to refine your design.

- Material selection: Guide you in choosing the best metal or polymer.

- Precision printing + processing: Seamlessly integrate additives