Building your dream proton pack: a comprehensive guide to 3D printing

Ghostbusters’ iconic proton pack is not only a movie prop, it is a symbol of nostalgia, engineering creativity and fan dedication. Thanks to advances in 3D printing, making your own screen-accurate proton pack has never been easier to access. However, achieving professional results requires precise, material expertise and meticulous post-processing. This guide will bring you the entire journey – from digital models to tough, ghost-deception reality – highlights how professional rapid prototyping services can enhance your build.

Why 3D printing is great for proton packs

Proton packs have complex details, organic curves and structural components that are difficult to replicate in traditional methods. 3D printing enables:

- Complex geometric shapes: Print winding tubes, vents and asymmetric parts in one breath.

- Massive customization: Scale parts, adjust designs or integrate personalized elements easily.

- Weight optimization: Iterates over a lightweight internal structure without sacrificing durability.

Still, desktop FDM printers often fall on large parts of packaging housings, such as packaging housings. Layer lines, warp lines and dimension limitations can undermine realism. This is where industrial 3D printing bridges the gap.

Step by step: Your Proton Package Manufacturing Roadmap

1. Design and document preparation

Start with high-quality STL files (from communities like Thingiverse or paid platforms). Key steps:

- Proportional verification: Make sure the parts match real-world dimensions (for example, the packaging is about 45 cm tall).

- Document repair: Use tools like NetFabB to fix grid errors.

- Support optimization: Placing support strategically to minimize scarring on visible surfaces.

hint: Split large components (e.g., cyclones) for manageable printing, enabling stronger build directions.

2. Material selection: Beyond PLA

Although PLA is popular for beginners, proton packs require toughness and heat resistance:

- ABS/Nylon: Ideal for structural parts. Resist fatigue and heat during motor/electronics integration.

- PETG: Balances printing and durability. Great for wearable parts.

- Metal components (via SLM): Laser illustrations for functional components aluminum or steel, such as fixtures, brackets or neutron wand tips. Combines lightweight strength and high-quality surface.

3. Printing: Accuracy is important

Large proton pack compositions require industrial-grade solutions:

- Avoid warping: Use a closed, temperature controlled printer such as industrial SLS or MJF to prevent layer spacing.

- Layer resolution: ≤100 microns retain details such as packaging dials and labels.

- Structural fill: Strengthen the load-bearing area of 30-50%.

At Greatlight, our SLM and multi-jet fusion systems produce low-hole, high-detailed parts. We address the common shrinkage and porosity problems in large prints, ensuring uniform density.

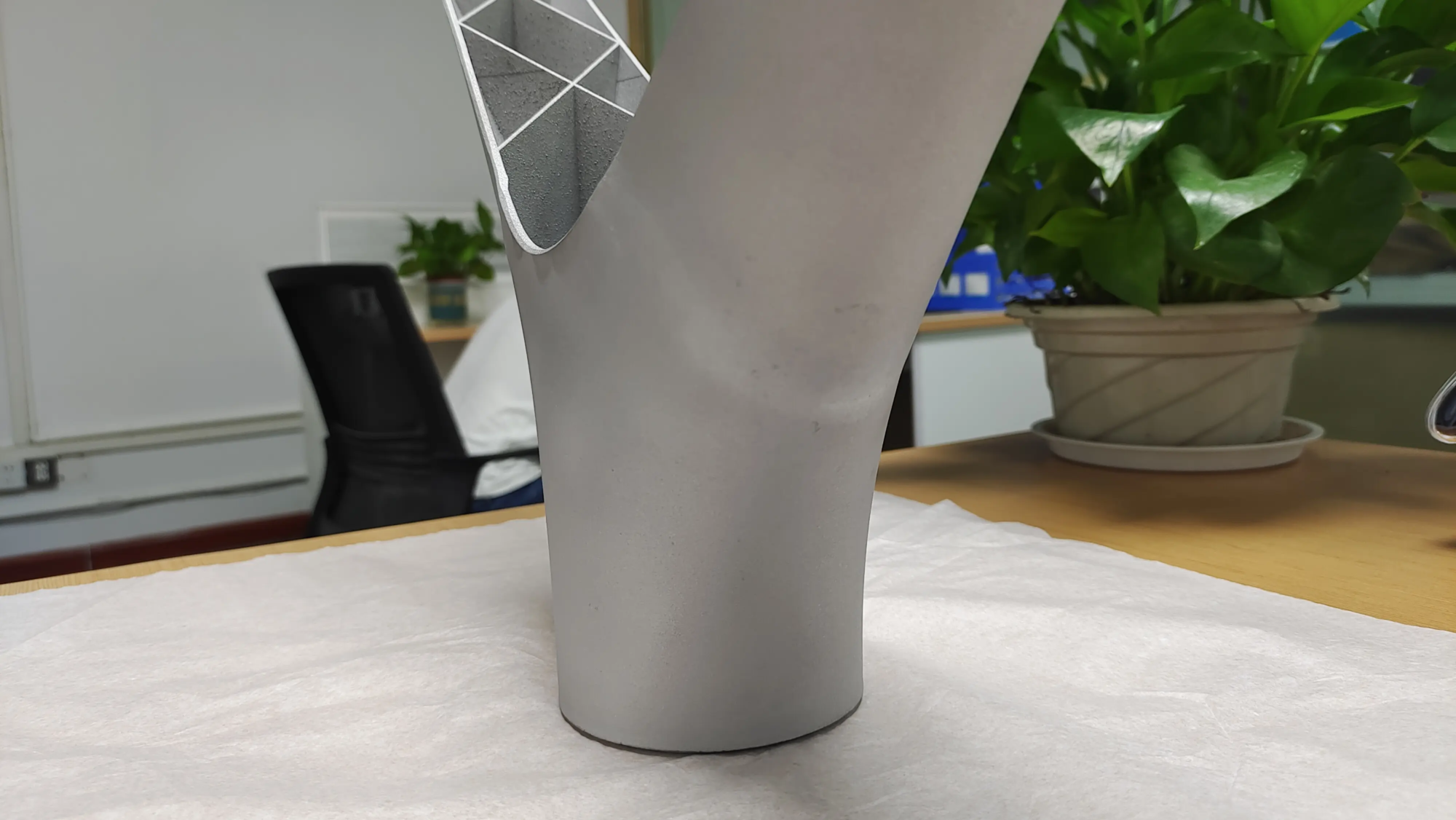

4. Post-processing: The secret to preparing the screen package

The original print needs improvements to achieve a weathered metal look:

- Grinding and smoothing: Starting from coarse sand (200), to the optical clarity part of 2000.

- Vapor Smoothing (ABS): Chemical treatment dissolved the layer lines.

- Start and Painting: Car fill primers hide defects. Then put the metal paint layer "weather" washing.

- Electronic integration: The route passes through the passage designed as a print.

bonus: Greglight offer One-stop post-processingincluding bead blasting, CNC-grade surface processing and custom weathering, saves over 20 hours of manual work.

Greatlight difference between proton bag manufacturers

As professional rapid prototyping leaders, we addressed challenges home printers cannot:

- Size capacity: Print parts up to 500mm using our industrial platform.

- Material versatility: Print in engineered resins, nylon and metals such as Alsi10mg or titanium (titanium) for easy stress fixtures.

- speed: Most orders ship within 72 hours, speeding up hobby projects.

- accurate: Achieve ±0.1mm tolerance for seamless components.

Whether you are printing a Ghostbusters Pack or having limited props running, our service ensures the quality of the movie that survives routine or role-playing duels.

Popular Tips: Combined method! Print complex geometry in nylon and reinforce the connector with SLM-printed metal hardware.

in conclusion

Build a proton package through 3D printing to blend fans with cutting-edge technology. However, device restrictions and post-processing bottlenecks can turn a passion project into frustration. By leveraging professional rapid prototyping services, such as Greatlight’s services, you bypass these barriers. Our SLM printers provide unparalleled strength for metal parts, while our painting and finishing services turn prints into museum-worthy props. Is it suitable to be prepared? Investment accuracy. After all, who do you call when you need flawless parts? Great.

FAQ: Proton Package 3D Printing

Q1: Can I print a proton packet on a consumer FDM printer?

Technically speaking,but this is labor-intensive. Desktop printers struggle with twisting and lacking detail on large belly parts. Professional SLS/metal printing produces stronger, cleaner versions.

Q2: Which 3D printing material is most suitable for proton packaging?

- Housing/cyclotron: Nylon 12 (SLS) – Lightweight, robust and beautifully sandy.

- Mount/button: Aluminum (SLM) – handles load-bearing stress.

- Wand Ingredients: PETG or engineered resin is used for grips and details.

Q3: How long does it take to pack full protons?

Using industrial equipment, a total printing time of about 100 hours was performed on high resolution. Greatlight’s printer fleet is produced in parallel, completing orders in less than a week.

Question 4: Can Greatlight handle electronic integration?

When we focus on prototyping, we can embed cavity, channel and mount to fit your LED/wiring specifications. The final assembly is still DIY.

Q5: What is the cost estimate?

Price range:

- DIY on the desktop: $250–$500 filaments + weekly labor.

- Professional Printing (Nylon): $800–$1,200.

- Premium version (with metal parts and finish): $1,500–$2,500.

Q6: Do I need my own STL file?

Yes. Provisioning verified STL. We will prepare, expand and optimize them – even add functional tweaks like screw ports.

Question 7: What post-processing services are recommended?

Our "Pro Pack":

- Solvent smoothing

- Car fill primer base

- Spray gun metal layer

- Customize the weathering of danger

Are you ready for proton size? Visit Greglight today Quotes about high-determined prints, materials that are resistant and fit for actors. Your ghost capture operation starts here.