introduce

The advent of 3D printing has revolutionized manufacturing, allowing unprecedented design freedom and rapid iteration. While metal 3D printing often grabs the headlines, high-performance polymers such as Polysulfone (PSU) Attracted for its excellent performance. For engineers and innovators, PSUs offer a compelling combination of thermal resistance, mechanical strength and biocompatibility, making them ideal for aerospace, medical and automotive applications. However, unlocking its potential depends on advanced printing technology and meticulous post-processing. This is what industry pioneers like huge light Level up your game. As a leading rapid prototyping manufacturer, GreatLight not only specializes in metal additive manufacturing, but also leverages the same precision in polymer projects. Their expertise ensures seamless conversion of functional PSU prototypes into production-ready parts.

Innovation in PSU 3D printing

Material progress

Traditional PSU faces limitations in printability due to its high melting point and tendency to warp. Innovation focus polymer composites: Mixing PSU with carbon fiber, glass or nanoparticles increases thermal stability (withstands temperatures >180°C) and reduces shrinkage. These engineered materials also improve interlayer adhesion, minimizing the risk of delamination in harsh environments.

Precision printing technology

Early PSU prints struggled with inconsistent extrusion and poor resolution. today, Industrial grade fuse fabrication (FFF) The system integrates the following functions:

- room heater Maintains precise ambient temperature (~150°C) to prevent thermal stress.

- Calibrate nozzle control Uniformly extrude sticky PSU with micron-level precision.

- Closed loop humidity control Reduces moisture absorption – a critical defect that causes bubbles or brittleness.

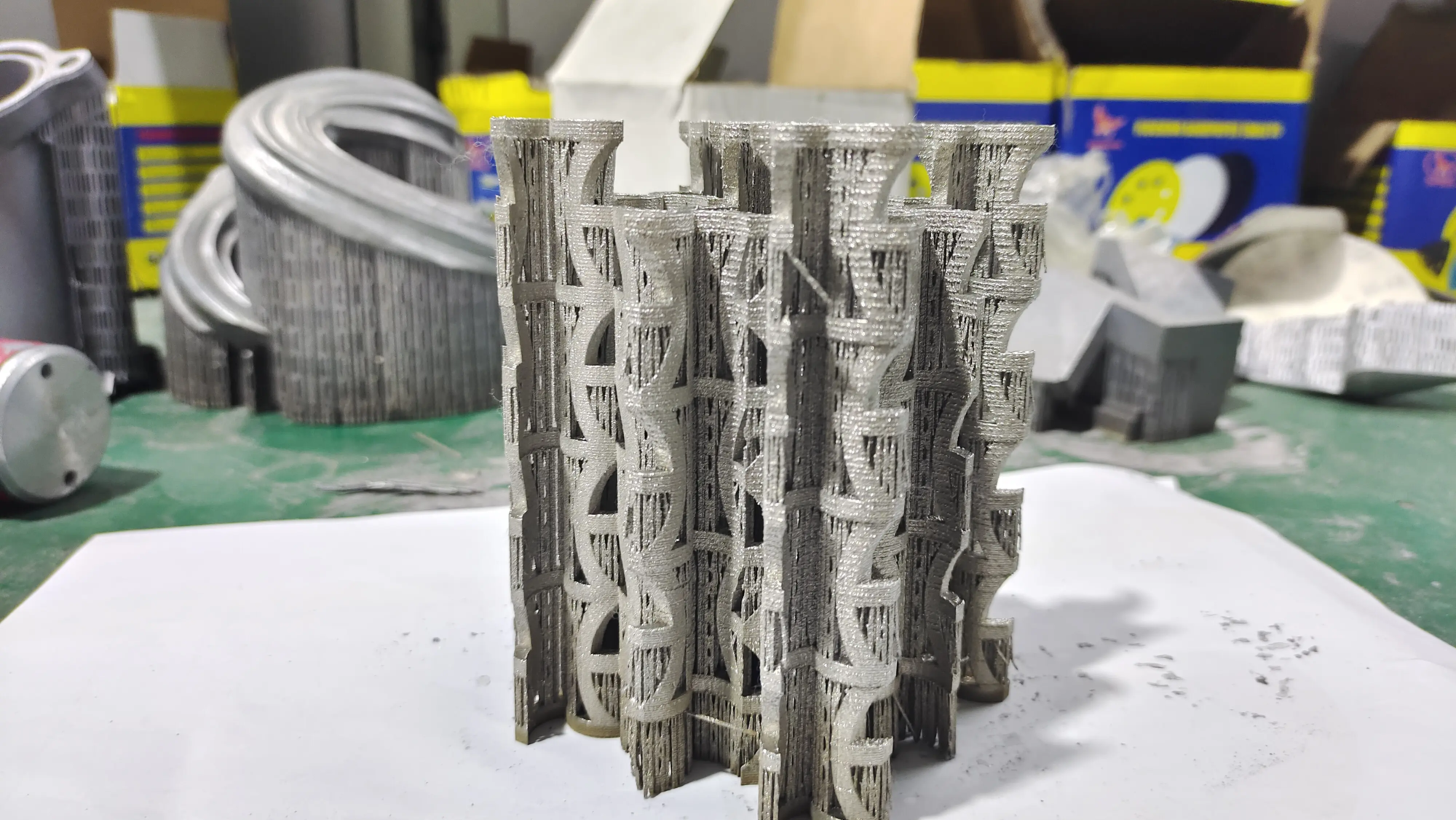

GreatLight uses these principles to deploy printers tailored to specialized polymers to ensure dimensional fidelity even for complex geometries.

A breakthrough in post-processing

The printing surface of PSU often requires modifications for end-use applications. Giant Light United Automatic CNC smoothing, micro sandblastingand solvent vapor polishing Achieve a finish close to that of injection molding. For medical components, they offer FDA-compliant sterilization and biocompatibility processing, which is critical for implants or surgical tools.

Cross-technology collaboration

play to their strengths Selective Laser Melting (SLM)GreatLight applies the same rigorous quality framework to polymers. Their metal 3D printing workflow (with topology optimization and failure analysis) for PSUs produces parts optimized for stress fracture and thermal fatigue.

Why power supply? Industry application

- medical: High temperature and pressure resistance make PSU ideal for reusable surgical instruments.

- aerospace: Maintains strength at low temperatures (–100°C to +150°C).

- car: Chemical resistance to oils and fuels for under-the-hood components.

GreatLight accelerates these use cases by One-stop prototyping to productionreducing delivery time from weeks to days.

in conclusion

PSU 3D printing is on the cusp of mainstream adoption, driven by innovations in materials science and sophisticated manufacturing protocols. company likes huge light Examples of how high-precision printing combined with integral post-processing can transform prototypes into robust end-use parts. In addition to polymers, their expertise in metal SLM makes them agile problem solvers – whether making titanium turbine blades or PSU biocontainers. For engineers exploring advanced polymer applications, integrating expertise from the prototyping stage ensures functionality and durability meet industry requirements.

Ready to experiment? Partner with GreatLight to push the boundaries of PSU innovation. Customize your project here!

FAQ

-

Can PSU replace metal parts?

In scenarios where lightweight design, chemical resistance, and electrical insulation are a priority, yes. However, consult an engineer for load-critical applications—metal composites often dominate in these areas. -

How does humidity affect PSU printing?

PSU quickly absorbs ambient humidity, causing bubbles or weak layers. Industrial dryers are necessary to dehydrate the filament before printing, and a controlled humidity chamber during the printing process is non-negotiable. -

What tolerances can GreatLight achieve using PSU?

Using a calibrated printer, they achieve standard tolerances of ±0.1 mm (±0.05 mm after processing). Complex assemblies benefit from iterative prototyping. -

Is PSU biocompatible for medical implants?

Unmodified The PSU is not implant grade but can be sterilized for surgical tools. For implants, ISO 10993 certified formulations are used following strict protocols. - Why choose Gretel over a competitor?

Their dual focus – cutting-edge metal/polymer printing and end-to-end finishing – ensures a seamless journey from CAD file to verified part. Combined with competitive pricing and fast turnaround (5-7 days), they can alleviate supply chain bottlenecks.

About Huilite:

As a top rapid prototyping partner from China, GreatLight combines advanced SLM printing, precision machining and material mastering to solve complex manufacturing challenges. From PSU prototypes to titanium aerospace parts, our integrated service model ensures unparalleled quality – faster and cheaper than traditional methods. Request a custom quote today.