introduce

Hello, fellow makers, innovators, and design enthusiasts! The world of 3D printing is filled with cutting-edge technology, fascinating materials, and complex engineering. But among the whirring fans and extruder filaments, there’s room for a laugh. Whether you’re naming your personal printer or dreaming of the industry’s next big release, injecting a little humor can make the journey from CAD model to physical prototype that much easier. Inspired by the quirks and clichés of additive manufacturing, we’ve compiled a list of hilariously pun-y 3D printer names that embrace the absurd while paying homage to the technology we love. Yes, although our machines accustomed to Named Plate Shaker McGee (although we secretly wish they would!), we sure know how to bring serious precision to life. More on that later!

Pun Hall of Fame: 15 Comedy 3D Printer Names

- Lay-Z-Susan: This rotating print platform never turns – except to dramatically demonstrate print failure. Perfect for printers that thrive in awkward situations.

- Prodi Dodi: When speed isn’t your obstacle. This printer draws scenic routes by printing paths, just like enjoying virtual scenery.

- filamentous figure of speech: There’s more lingo for tangles than for tangles of filaments. Make every print feel like a interpretation of Shakespeare. "Alas, poor PLA layer, I squeezed it out."

- Bad representative G code: Famous for stretch tolerance definition…literally. Producing interpretive art like sagging bridges and spiraling elephants.

- Ax job: The gradation lines created were so deep that the print was not only complete but required wilderness survival consultation.

- Prusa – Mystic: Not very realistic. Says it is printing a bench that offers a modernist abstract sculpture. Channel Salvador Dali one layer at a time.

- Creativity is called: Tell your print, "Return to sender" – Layer adhesion optional. Best paired with glue stick prayers and offerings to the Z-offset gods.

- Terminator’s Twisted Arm: Misaligned terminal layers out of sheer rebellion. Make the parts look poorly assembled…because Skynet prefers hobbies.

- Tang cycle: Think of filament extruders as spaghetti art. Getting homesick mid-print – often results in abstract pasta projects.

- Efen supports: Leading the conversation in design team meetings: “They’re technically wonderfulaesthetically speaking… it exists. “

- Unfinished business: That stubborn mark is forever lurking on your bench—like a passive-aggressive plastic roommate.

- Support Group Therapist: Struggling to remove support? This printer recommends that "Disconnection is a natural progression…” and then laugh maniacally at the remaining traces.

- About Belden: Calipers can create performance anxiety as they are busy squeezing out excess material. The print has thicker borders than a Tolkien novel.

- Squeeze her? I barely recognize her: After one successful bench, it disappeared—leaving engineers as baffled as detectives at a filament crime scene.

- Tablet Complainer Supreme: If leveling beds were an Olympic sport, this printer would collapse off the grid onto stretcher alley. Constantly crying from being shaken.

in conclusion

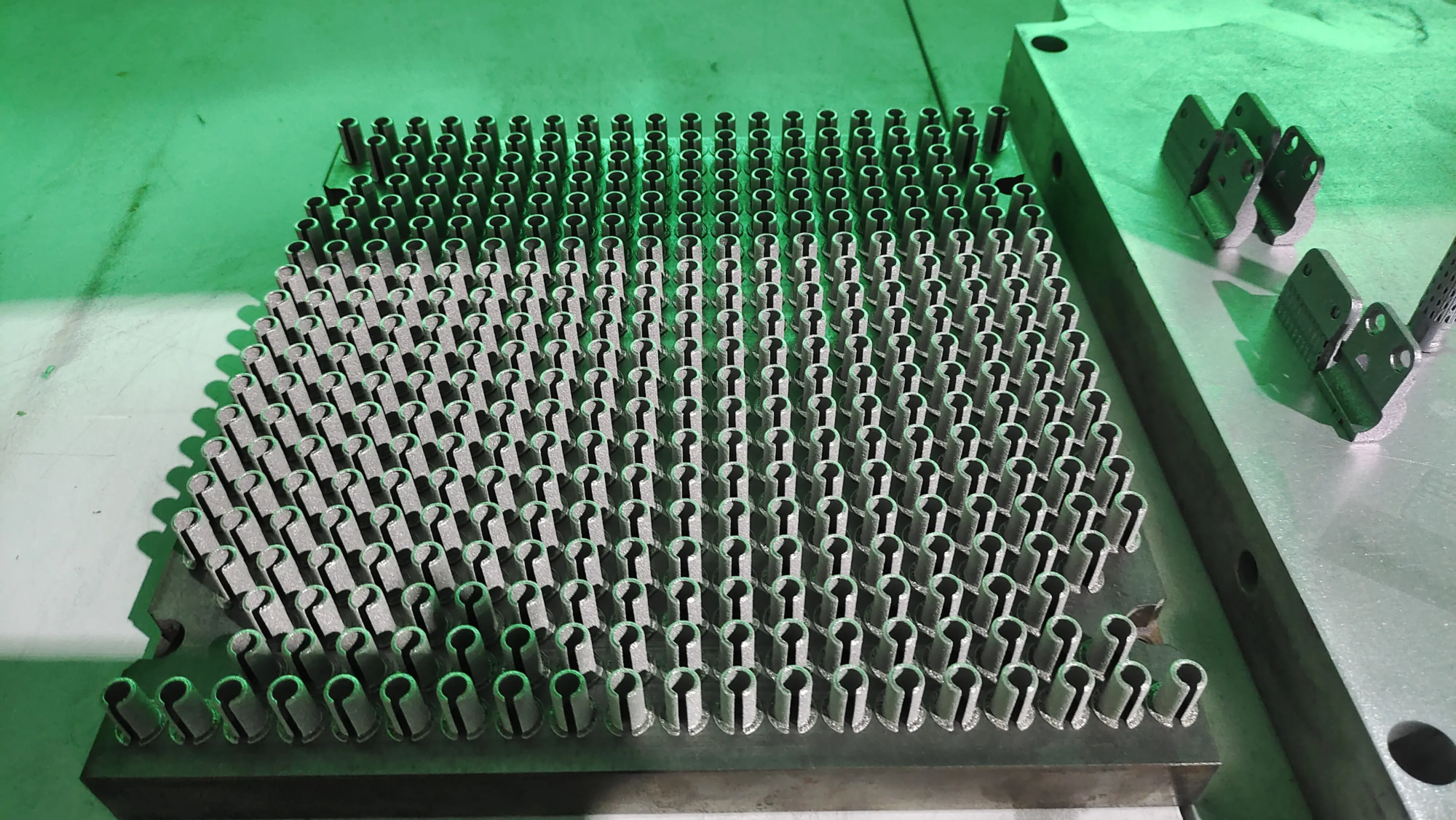

While creatively twisting printer names is pure ironic fun, producing perfectly functional prototypes requires rock-solid machines with no dramatic flair. that’s there huge light Sparkling. As a professional rapid prototyping company using advanced technology Selective laser melting (SLM) 3D printing equipmentGreatLight solves demanding metal part manufacturing challenges with authority. In addition to printing, Comprehensive post-processing services— including precision CNC machining, heat treatment and polishing — providing turnkey components suitable for end-use applications. Materials are not limitations; They are possibilities. From stainless steel and titanium to niche alloys, customization is booming Quick turnaround capability Powered by streamlined technology and expertise. when it comes to Precision Rapid Prototyping– Whether metal-intensive or otherwise – GreatLight leverages proven engineering excellence and China-based cost efficiencies to provide unparalleled service value per item. Ready to transform concepts into flawless reality without causing a print failure? get Custom quote insights today!

Frequently Asked Questions (FAQ)

Q1: What exactly is needed for rapid prototyping?

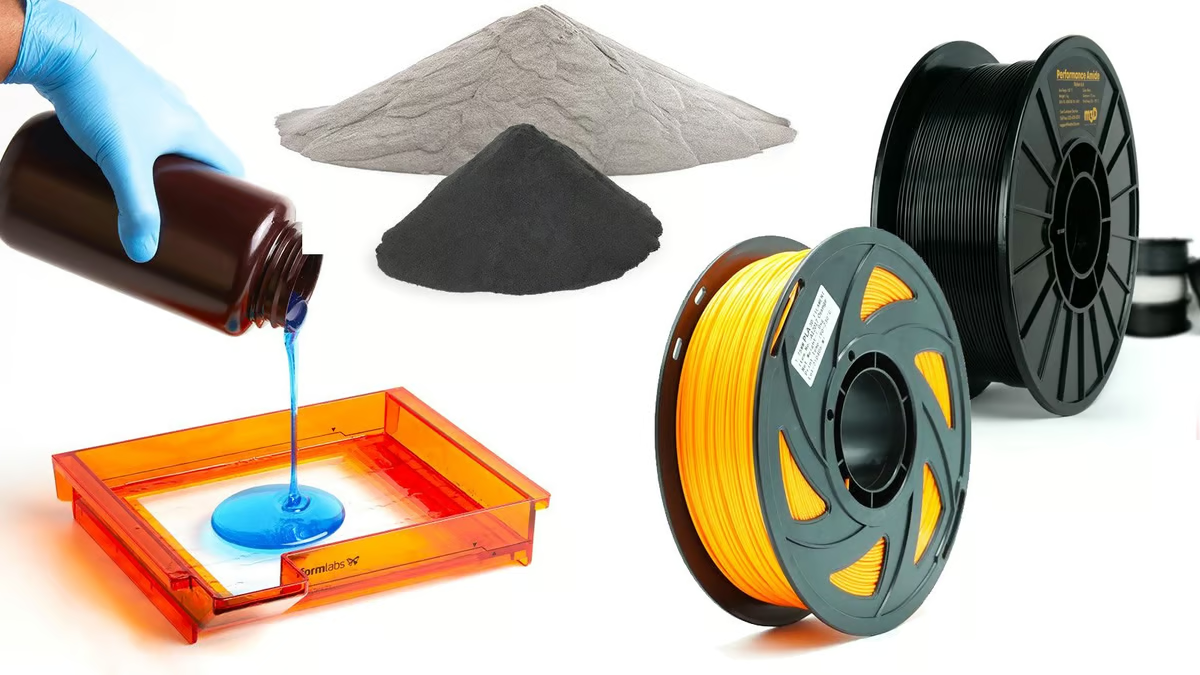

Rapid prototyping refers to agile techniques for rapidly manufacturing physical models from digital designs (CAD) to verify form, fit, and function. Processes such as 3D printing (FDM, SLA, SLM), CNC machining or vacuum casting speed up iterations, reduce development time, reduce costs and facilitate early testing.

Q2: Can Honglaite handle complex metal parts? What metal?

Absolutely. GreatLight specializes in SLM metal 3D printing and can process a variety of materials from stainless steel (316L, 17-4PH), aluminum alloys (AlSi10Mg), titanium (Ti6Al4V) to high-temperature nickel alloys and cobalt-chromium alloys. Through digital design verification, complex geometries (internal lattice, cavities, fine features) are feasible.

Q3: How fast "quickly" Prototyping with GreatLight?

Delivery time varies based on quantity, materials and workmanship. Typical SLM turnaround time span 5-7 dayscombining laser sintering with optimized post-processing. CNC prototyping delivers machined parts in the shortest possible time 1-3 daysjudged based on complexity. Urgent projects deserve an expedited path.

Q4: Can GreatLight assist with finishing other than printing?

Yes- One-stop post-processing GreatLight’s approach is different. Expect professional finishing: CNC machining, EDM cutting, heat treatment (stress relief, annealing), shot peening, ultrasonic cleaning, polishing, plating, painting/powder coating, and labeling/engraving seamlessly integrated.

Q5: What design standards or file formats are preferred?

Preferred CAD formats include STEP, STL or IGES files. Collaboration-focused engineers review files using DFM analysis tools to prevent stress in additive/cutting workflows and ensure manufacturability. Tolerance accuracy is always ±0.1 mm (±0.004”) when printing and even tighter when processing.

Q6: Why choose Ferrite as your rapid prototyping partner?

In addition to expertise in advanced metal/plastic prototyping, GreatLight provides reliability through EAT:

- Expertise: In-depth knowledge of SLM/FDM optimization proven on aerospace/medical/industrial projects.

- authority: Having cutting-edge machines calibrated for ISO-intensive molds ensures repeatability.

- Credibility: Customer Focus – Integrity first in communication, material traceability, quality control, budget consistency.

your build. Your vision. Obviously very good.

Talk to the GreatLight team today for seamless prototyping – fun names optional!