Unveiled Qidi Tech X-Max 3: A powerful desktop 3D printer for review

The landscape of professional desktop 3D printing continues to evolve, pushing the boundaries of industrial environments that may be outside the world. Enter the Qidi Tech X-Max 3, the latest flagship from a manufacturer known for its robust machines. The X-MAX 3 is positioned as a major leap, promising industrial caliber performance, larger build volumes and advanced features, all packaged for manufacturers or professional workshops. But can it be delivered? We find out through its pace.

First impression and construction: industrial standpoint

Disassemble the X-Max 3 and convey its purpose immediately: carefully print it. The machine features a large full metal fence with large glass doors on the front and sides, providing easy access and excellent visibility during print. The high-end model of Qidi Tech is marked by a solid and durable build quality. The dual drive extruder system is significantly installed, suggesting its high flow capability. A new touch screen interface replaces the older knob system, providing a more modern user experience. The overall footprint is larger than its predecessor, but it is reasonable due to the extended build volume (generous 325 x 325 x 325 mm).

Key Features and Technical Specifications: Filling Performance

The X-Max 3 is not only big. It is full of features designed for demanding users:

- Core motion system: Compared to rods and bearings, using linear guides on all shafts (X, Y, Z) significantly improves accuracy, stiffness and reduced maintenance. This translates into better printing quality, especially on higher speeds and large prints.

- Double room heating: A major standout. The printer actively heats the build chamber (up to 70°C) and the printing bed (up to 120°C). This is essential for efficient printing of high-temperature engineering materials (e.g., Peek, Pekk, Pei), minimizing distortion and ensuring consistent layer adhesion – a price point that is rare.

- Ultra-high direct extruder (HSD technology): With dual high torque motor, larger diameter heating block, and "Maglock" Nozzle system (no tools, faster nozzle exchange speed). This setup is good at pushing filaments quickly (although practical speeds depend on the material, up to 600mm/s can be claimed), including abrasive composites and high temperature filaments.

- Smart Pierce Air System: A unique surround airflow system that dynamically adjusts cooling according to printhead position, effectively cooling the overhang without disturbing chamber temperature – balancing cooling requirements with material thermal requirements.

- Enhanced electronics and connectivity: Powered by the new SOTA control board for faster processing, independent channel control for each heater and sensor redundancy (dual thermistor/extruder motor temperature). Features include built-in camera (enable for time delay), Wi-Fi (remote monitoring via the Qidi Print app), Ethernet and USB.

- Chamber filtration: Included is a dual HEPA+ activated carbon filter system to capture ultrafine particles (UFP) and VOC, which improves work environment safety and is especially important for materials such as ABS or Nylon.

Performance: Where rubber meets the road

Our testing focuses on versatility and reliability:

- High temperature materials: Printing engineering silks such as Uletem (PEI) and PEEK are impressive. Maintaining stable high temperatures with dual chamber heating is crucial for thermal management. Most of the twists are rarely seen, which proves a closed, actively heated environment. These are violent materials that many printers of similar prices cannot reliably handle.

- Printing quality: In PLA, PETG, ABS and nylon, the X-Max 3 provides exceptional cleaning results. The surface is smooth, the layer lines are consistent and delicate, and the details are clear. Linear tracks and rigid frames minimize vibration, even at medium-high speeds. With Pierce Air System, Orshangs and Bridges print great. The calibration prints have excellent dimensional accuracy.

- speed: It is not always practical to reach a theoretical maximum of 600mm/s on a simple PLA filler, but the X-Max 3 is always faster than the traditional Corexy Bedslingers While maintaining excellent quality. For functional parts, using speeds of around 200-350mm/s yields excellent and efficient results.

- Noise and reliability: The machine is quieter than many competitors with similar features, especially at moderate speeds in the basement temperature. We have not experienced filament jam or hardware failures during long testing. The automatic bed leveling speed is fast and accurate.

- Software (Qidi Slicer): Based on Cura, Qidi’s forks are intuitive and optimized for the X-Max 3, including specific curves for a variety of materials. Power users will appreciate its advanced features. Integrate with cameras and printers for smooth remote monitoring.

Advantages and Disadvantages: Balance Scale

advantage:

- Unrivaled desktop features for high-speed engineering materials (PEEK, PEKK, PEI).

- A large number of actively heated chambers enable large, warped-free prints.

- Excellent build quality, speed and accuracy with linear guides on all axes.

- Powerful direct drive extruder handles demanding filaments easily.

- Smart Pierce air cooling minimizes drape problems without damaging indoor temperatures.

- Significantly reduce the improvement of noise reduction.

- Excellent standard features: camera, Wi-Fi, advanced filtering, touch screen.

shortcoming:

- Large Footprints – Requires a lot of desktop/workshop space.

- The high price tag reflects its functionality, but positions it at the high end of the manufacturer’s market.

- Although the touch screen UI is popular, it has a lower response rate than its top competitors. Firmware updates and improvements are welcome.

- High power consumption when heating large chambers to the highest temperature.

Conclusion: Desktop industry competitors

The Qidi Tech X-Max 3 is not only an incremental upgrade; it is a redefinition that desktop FDM printers can achieve, especially in high temperature materials. If your workflow involves functional prototypes, fixtures, fixtures, or end-use parts that require strength and thermal resistance of engineering grade polymers such as PEEK or PEI, the X-MAX 3 offers features that were previously only found in more expensive industrial machines. For users who consistently drive restriction through demanding applications but are limited by space or budgets of industrial units, it can be said that the X-MAX 3 is unparalleled in the producer segment.

While its size and premium cost means it is not for everyone, for professionals, advanced manufacturers and prototype workshops, large format, high temperature printing without compromise, the QIDI Tech X-Max 3 is a truly powerful force and a compelling investment in production capacity. It combines powerful industrial capabilities with desktop accessibility and ease of use, making cutting-edge material printing a viable desktop reality.

FAQ: Qidi Tech X-Max 3

-

Q: What material does Qidi Tech X-Max 3 print?

one: The X-Max 3 has a wide range of ranges, including PLA, ABS, PET, TPU, Nylon (PA), PC (polycarbonate), PET, PVA, PVA, hips and crucial, high-temperature engineering thermoplastics such as PEEK, PEKK, PEKK, PEI (PEI (PEI), PPSU/PPSU/PPSU/PPSF and CABON FIBER COMPOSITES. -

Q: How hot is the build room? Do you really have the ability to peek?

one: The actively heated chamber can reach up to 70°C. Combined with high bed temperatures (up to 120°C) and advanced thermal management, Reliable Print peeps and other demanding high-temperature materials, where chamber stability is critical to prevent warping and ensure layer adhesion. At this price point, this is one of its excellent features. -

Q: How fast can it actually print?

one: Although the Qidi advertises speeds up to 600mm/s, the practical speed of high-quality results depends largely on the geometry of the material and model. For PLA and PETG, speeds of 200-350mm/s can be easily achieved in optimized configuration files while maintaining excellent quality. Beyond this usually requires a significant trade-off. It’s significantly faster than old-fashioned machines, especially when it comes to filling and traveling movement. -

Q: How noisy is the X-Max 3?

one: Qidi has made great progress in reducing noise. Running at lower room temperature and medium speeds, it is significantly quieter than many comparable high-speed printers. Fan noise becomes more prominent at maximum speeds or when indoor heaters are actively working hard (e.g., up to 70°C or heating during high-speed material printing), but is usually manageable in workshop environments. -

Q: Does it have an automatic bed leveling system?

one: Yes, it has a very effective automatic bed adjustment system. It’s easy to run and ensure a great layer of adhesion on a large build board. -

Q: What software does it use?

one: It mainly uses Qidi Slicer, a custom version of Cura, which has made sufficient adjustments to the X-Max 3 and includes optimized profiles for various materials. It can also be used with other configurations such as Prusaslicer or Simplefify3D, such as Prusaslicer. - Q: Is it worth upgrading from X-Max 2?

one: Absolutely, if you need significantly higher speeds, you can print exotic high temperature materials (PEEK/PEKK), larger build volumes, linear guides for improved accuracy or improved noise levels, and a modern touch screen interface. The X-MAX 3 represents a substantial generational leap.

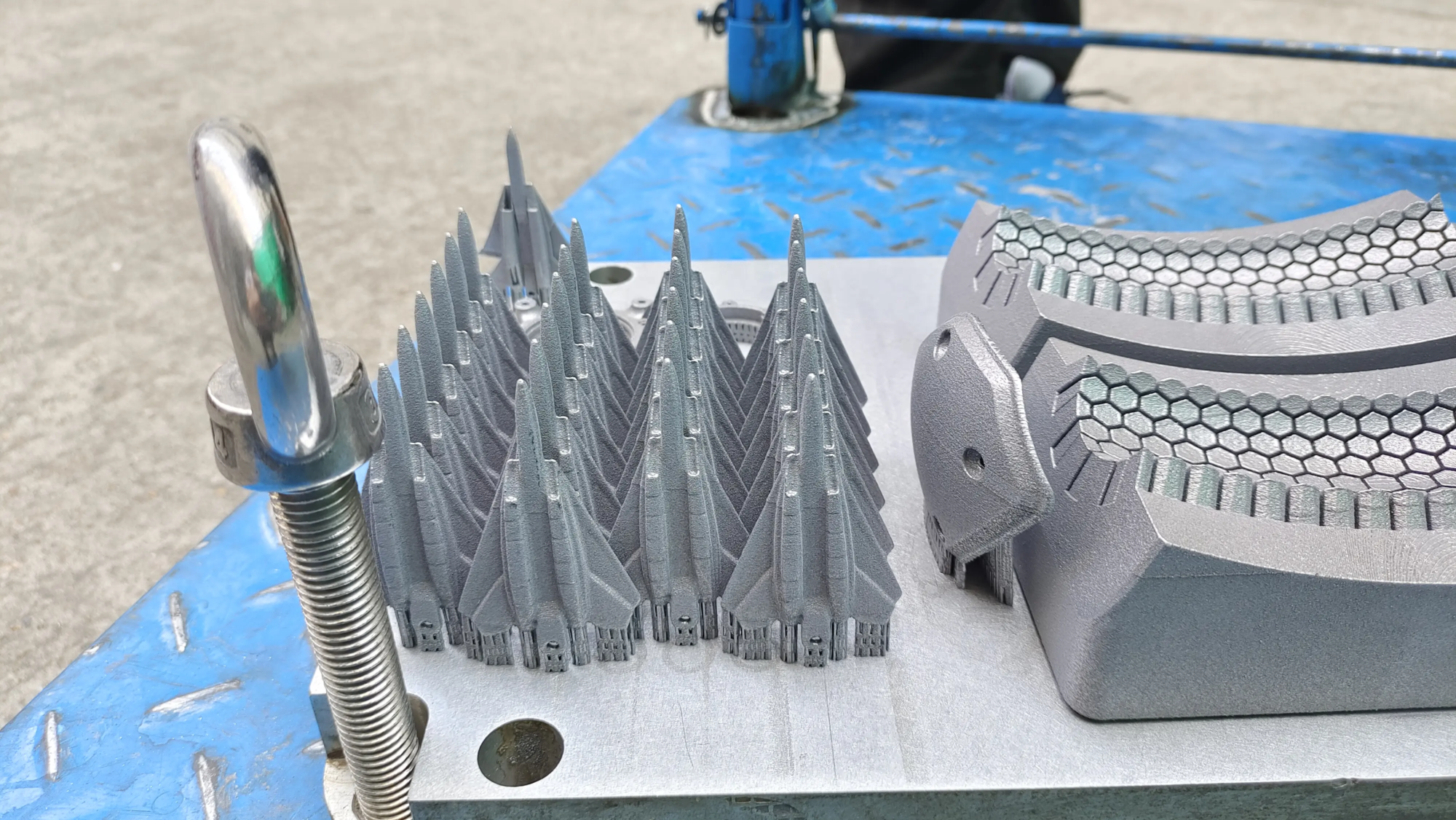

Need professional desktop printing other than metal prototypes?

While the Qidi Tech X-Max 3 can have a good grasp of what requires polymer prototyping, some projects require the strength, accuracy and thermal properties of the metal. This is the place where professional manufacturing expertise is.

Great Standing in the lead Rapid Prototyping Manufacturer Headquartered in China. We specialize in overcoming the hardest Rapid Prototyping Challenge of Metal Parts By our Advanced SLM (Selective Laser Melting) 3D Printing Technology and the most advanced production process.

Go beyond FDM functionality and have Greatphiel:

- Advanced SLM devices: Power made from metal additives is used to obtain complex high-strength components.

- End-to-end solution: Benefit from us One-stop post-processing and completion service – Includes heat treatment, CNC machining integration, surface finish (polishing, grinding, coating) and quality control testing.

- Material versatility: Handle various metal alloys (Stainless steel, aluminum, titanium, inconel, tool steel, copper, cobalt chromium) – Most materials can be customized Meet your exact requirements.

- Speed and accuracy: We understand the need for fast turnaround without sacrificing quality. Quick customization and processing Functional metal prototypes and small volume production parts.

- Engineering Cooperation: Our team works with you to solve complex design and manufacturing problems Precise processing Integration.

harsh Custom precision machining and metal prototype requirements, Greatlight has established itself as one of the best rapid prototype companies from China.

Now customize the precision of fast prototype metal parts at competitive prices. Contact Greatlight now to unlock the potential of high-performance metal components.