Unlocking Innovation: Basic Guide to Metal 3D Printing (Attention to SLM Technology)

The world of manufacturing is undergoing a fundamental transformation, with metal 3D printing firmly located in the epicenter. This technology, especially selective laser melting (SLM), has evolved from a niche prototyping tool to a critical production method that enables the creation of complex, robust metal parts that were previously impossible or expensive. This guide delves into the core of metal additive manufacturing, explains SLM, its processes, benefits, applications, and why working with experts like Greatlight is crucial to unlocking its full potential.

Learn about Power Type: Selective Laser Melting (SLM)

SLM is usually the preferred technology that requires metal applications and is the powder bed fusion process. Imagine a fine layer of metal powder, usually only 20-60 microns, spread evenly on the construction platform. The layer is then carefully scanned by a high-power laser beam, selectively melting the powder particles according to the part’s digital blueprint (CAD file) to fit the specific slice. Once the first layer is completed, the build platform will drop, apply a new powder layer, and then repeat the laser melting process to fuse each new layer to the lower layer. This layer-by-layer method directly constructs solid metal parts in the powder bed.

- Key Features of SLM:

- Complete melting: SLM completely melts the metal powder, resulting in nearly full density parts (usually over 99.5%), with mechanical properties comparable to traditional forged materials and sometimes superior.

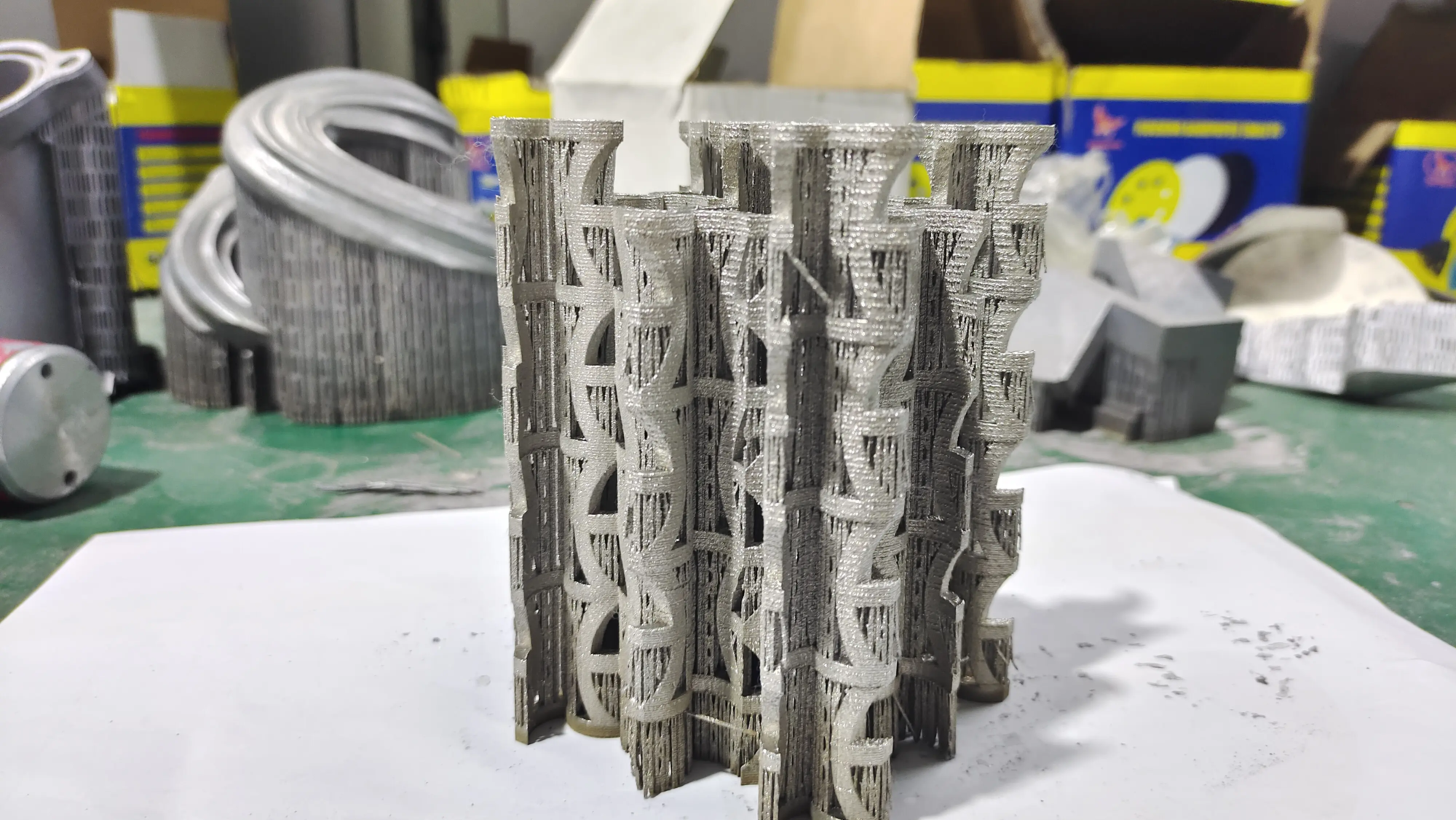

- Complex geometric shapes: It excels in producing complex internal channels, lightweight rosary, organic shapes and highly optimized topology that violate conventional manufacturing (such as milling or casting).

- Material versatility: Compatible with a wide range of high-performance metals and alloys including stainless steel (316 liters, 17-4ph), titanium (Ti6al4v), aluminum alloy (ALSI10MG, Scalmalloy), nickel alloy (Inconel 625, 718), Chome Chrome and Toolselels.

- Minimum waste: Materials are used efficiently because unused powders can be filtered and reused for subsequent construction.

Metal 3D Printing Journey: From Digital Files to Completed Parts

- Design and Optimization: Everything starts with a 3D CAD model. This stage usually involves designing additive manufacturing (DFAM) principles to take advantage of the technology – solidifying components, optimizing weight, integrating functionality and ensuring printability. Advanced simulation software can predict stress and deformation.

- File preparation and slicing: The CAD model is imported into the dedicated printer software. Support structures are actually added, the support structures necessary for drape characteristics and for managing thermal stress. Then the model "slice" Divided into hundreds or thousands of thin digital cross-sections.

- Printer Setup and Calibration: The construction chamber is sealed and filled with inert gas (argon or nitrogen) to prevent oxidation of the molten metal. The metal powder raw material is loaded and the system is carefully calibrated.

- SLM build: The laser scans each layer based on the sliced data, selectively melting the powder. Recoater Blade spreads new powder for each subsequent layer. Settlement time varies from hours to days, depending on part size and complexity.

- Powder removal and recovery: Once completed, the build chamber is usually cooled under an inert gas. this "cake" Remove parts containing uninsert powder. Collect, siev, test and prepare to reuse excessive powder.

- Post-processing (key steps): Carefully remove parts from the build platform (usually via wire EDM). Basic post-processing steps include:

- Support removal: Mechanical and/or chemical techniques break away from the support structure.

- Relieve pressure/heat treatment: Static pressures such as annealing or heat (hip joint) can significantly improve mechanical properties, reduce residual stress and ensure dimensional stability.

- Surface finish: Options range from basic bead blasting to precision machining, CNC milling, polishing, grinding and a variety of coating processes to achieve the desired tolerances, surface roughness or aesthetics.

- Check and Verification: The final section is subjected to a rigorous inspection (dimensional inspection, visual inspection, material testing, NDT, such as X-ray or CT scans) to meet quality specifications.

Why 3D printing of metal? Key Advantages

- Unprecedented design freedom: Get rid of the constraints of the subtraction method. Create complex internal functions, fluid-optimized forms and lightweight lattice structures.

- Rapid prototype and iteration: The development cycle has been greatly shortened. Produce functional metal prototypes for testing and design verification within days rather than weeks or months.

- Parts merge: Combining multiple component components into a single printed part reduces weight, assembly time, potential failure points and inventory.

- Massive customization: Economically produce customized, small batch or on-demand parts tailored to specific requirements.

- Enhanced performance: Optimize parts for specific functions (e.g., heat dissipation, fluid flow, strength-to-weight ratio) through traditional manufacturing.

- Material efficiency: Using only the materials (+support) required to build parts greatly reduces waste compared to processing.

Location of metal 3D printing: Application

- aerospace: Lightweight structural components, complex nozzles, heat exchangers, turbine blades, satellite components.

- Medical and Dental: Patient-specific implants (spine, cranial, crown/bridge), surgical instruments, orthopedic equipment.

- Cars and Motorsports: Lightweight components, sophisticated brackets, custom fixtures and fixtures, heat-resistant engine parts.

- Industry and Tools: Inject conformal cooling channels in molds to provide faster cycle times, durable fixtures, fixtures, custom weapon end tools.

- vitality: Components of turbines (gas, wind), heat exchangers and complex oil and gas parts.

Why Greatlime for your metal 3D printing needs?

Successfully harnessing the power of metal 3D printing, especially the capabilities of SLM, requires not only machines. It requires deep expertise, meticulous process control and comprehensive post-processing. This is GreatAmong the leading rapid prototyping companies in China, people are really good at:

- Cutting-edge SLM technology: We invest in state-of-the-art SLM 3D printers to ensure accuracy, repeatability and gain advanced manufacturing capabilities.

- The depth of material knowledge: Our engineers have deep expertise in a wide range of metal alloys. We guide you in material selection and ensure optimal metallurgical characteristics printing parameters.

- End-to-end solution: Gregtime is your single partner for the entire process. From the expert Design for Additive Manufacturing (DFAM) Consulting accurate SLM Printing Crucial One-stop post-processing and completion servicewe handle it all. This comprehensive approach ensures quality and coordination, saving time and complexity.

- Customization and speed: "Most materials can be customized and processed" Not only is a promise – this is our operating standard. We focus on custom precision machining and fast turnaround times without compromising quality.

- Key points of solving problems: Our team thrives "Professionally solve the problem of rapid prototyping of metal parts." We bring engineering acumen to address design challenges, material complexity and production barriers.

- Excellent competition: We offer extraordinary value and are considered "One of the best rapid prototype companies" To integrate technical strengths, expert services and a commitment to cost-effectiveness. Customize your precision fast prototyping parts now at the best prices!

in conclusion

Metal 3D printing, led by SLM technology, is not only a manufacturing alternative. This is a paradigm shift that has brought the industry to leap forward innovation. It enables engineers and designers to go beyond traditional limitations, creating more powerful, lighter, more complex and powerful parts faster than ever before. Despite the great potential this technology brings, its complexity, from design optimization and materials science to precise printing and critical post-processing, is proven expertise. Work with experienced and reliable providers Great Mitigate risks, accelerate your development cycle, and ensure you extract the maximum value from this revolutionary technology. Embrace the future of manufacturing. Let Greatlight shed light on the path from complex ideas to flawless high-performance metal reality.

FAQ: Metal 3D Printed Belt

-

Q: What is the difference between SLM and DML?

one: Both are powder bed fusion technology. SLM is often designed to melt in full, creating fully dense parts (for functional metals). DML (Direct Metal Laser Sintering) sometimes means partial melting/sintering, although the terms are usually used interchangeably. Greglight mainly uses SLM technology to achieve optimal density and mechanical properties. -

Q: How strong are SLM parts?

one: When properly treated (including proper heat treatment/hip), SLM parts can be obtained or exceeded by the mechanical properties of traditionally forged, cast or processed ingredients (tensile strength, yield strength, fatigue life). -

Q: Which materials can be printed with which materials?

one: We have extensive experience in common aerospace, medical and industrial alloys: stainless steel (316L, 17-4PH), titanium alloy (TI6AL4V, CP-TI), aluminum alloy (Alsi10mg, Alsi12), nickel-based Superalloys (Inconel 625, 718, 718), Chrole ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant ant an -

Q: What accuracy and tolerances can I expect?

one: Tolerances for current printing are usually ±0.005" To ±0.015" (±0.1mm to ±0.4mm), depending on the part size, geometry and material. Our Comprehensive post-processing and completion functionsincluding CNC machining, allows us to achieve tighter, precise tolerances according to the requirements of your application. -

Q: How does Greatlight handle post-processing?

one: We provide a real One-stop service: Dedicated support removal (mechanical, chemical); critical stress relief and heat treatment (including hip); and a complete set of finishing options (sand/bead blasting, tumbling, polishing, CNC machining, grinding, coating). This ensures that your parts are running properly and meets all specifications before delivery. -

Q: Is metal 3D printing cost-effective?

one: It usually performs complex, lightweight or low-volume production operations in situations where traditional tool costs or design complexity make processing inefficient. For prototype or custom parts, it may be faster and more economical despite the higher material costs compared to batch processes. Greatligh’s focus is on providing The best price Pass effective processes and avoid hidden costs of managing multiple vendors. - Q: How to start a project with Greatlight?

one: Just contact us! Provide your CAD files and requirements (materials, quantity, tolerances, applications, post-processing requirements). Our experienced engineering team will review your designs, provide DFAM advice, provide detailed quotes, and effectively guide you through the process. Let’s solve your metal rapid prototyping problem.