The Magic of Rainbow Filament: Bring Brilliant Color to Your 3D Prints

In the ever-evolving world of 3D printing, innovation is not just about functionality, but also aesthetics and expression. Gone are the days when uniform gray or monochromatic prints dominated the scene. Enter rainbow silka dazzling material that transforms ordinary prints into vibrant, color-changing masterpieces. It’s not just a filament; It’s a creativity tool that enables amateurs and professionals alike to inject personality and artistry into every layer of their designs.

What exactly is rainbow silk?

Rainbow filament is a specially formulated thermoplastic (usually PLA, PETG, or ABS) that has a continuous color transition along its length. As the filament unwinds during the printing process, it cycles through a vibrant spectrum of colors – often including shades of red, orange, yellow, green, blue and violet. Transitions can be subtle gradients or bold, unique segments, depending on the specific filament brand and manufacturing process. Blending multiple filaments doesn’t create this magic; instead, it involves complex co-extrusion technology that combines colored resins into a single strand, ensuring smooth, seamless color changes.

The allure of rainbow prints: more than just pretty colors

Why choose rainbow filament over standard monochrome options? The benefits are compelling:

- Unparalleled visual impact: The project immediately became a compelling conversation topic. Whether it’s a functional tool stand, decorative vase or toy, the ever-changing colors add a dynamic, captivating quality that static tones simply can’t match.

- Cost-Effective Creativity: Traditionally, creating multicolor prints required multiple filament changes, complex slicing setups, or expensive multi-material printers. Rainbow filament effortlessly achieves stunning multi-color effects in a single extruder.

- Design Versatility: It breathes life into organic shapes or complex geometries, where color transitions naturally follow contours, highlighting curves and details. Prints for art sculptures, jewelry, lampshades and toys gain an extra dimension.

- Motivation and fun: Watching your creations unfold in unpredictable, beautiful color patterns adds a layer of excitement to the printing process, inspiring enthusiasm and a spirit of experimentation.

Conquering the Rainbow: Secrets to Successful Printing

Although rainbow filament is beautiful, it requires special attention to printing parameters to obtain the best results:

- Layer height and print speed: The higher the layer height, the more pronounced the banding between colors. Finer layers (e.g. 0.15-0.2mm) produce smoother gradients. Moderate print speeds ensure consistent extrusion of different plastics.

- Temperature consistency: Make sure your hot end maintains a stable temperature. Fluctuations can amplify unexpected bands. If possible, use a shell.

- Retraction settings: Fine-tune retraction to prevent color "bleed" or "ooze" At layer start/stop points. Compensates for the slightly different flow characteristics of colored polymer blends.

- Model orientation: Color changes linearly with the length of filament consumed. Vertically oriented models typically produce longer, flowing gradients, while horizontally oriented models produce fast streaks. Experiment and see the effect!

- Know your filament: Transition speed and color order vary widely between brands. Check the spool markings (if any) and manufacturer specifications. Pre-print a small test block to show the pattern.

Where Rainbow Silk Really Shines: Applications

The applications of rainbow filament are very wide and growing:

- Art and Decoration: Sculptures, vases, pots, coasters and lampshades become unique works of art.

- Fashion and Accessories: Create eye-catching jewelry, phone cases, key chains, hairpins and cosplay prop elements.

- Functional items: Transform practical items like tool handles, coasters, organizers or bookends into visually engaging pieces.

- Education model: Enhance anatomical models, molecular structures or topographic maps with intuitive color transitions.

- Marketing and Promotional Projects: Create a memorable branded giveaway, trophy or display.

- Just for fun: Fun reaches new heights with toys, puzzles, figurines and gifts.

Beyond Rainbow PLA: Professional Prototyping Accuracy

While rainbow filaments unlock incredible aesthetic possibilities in fused deposition modeling (FDM), complex functional prototyping—especially involving metal parts——Requires professional knowledge and industrial-grade technology. This is where working with professional rapid prototyping manufacturers e.g. huge light become priceless.

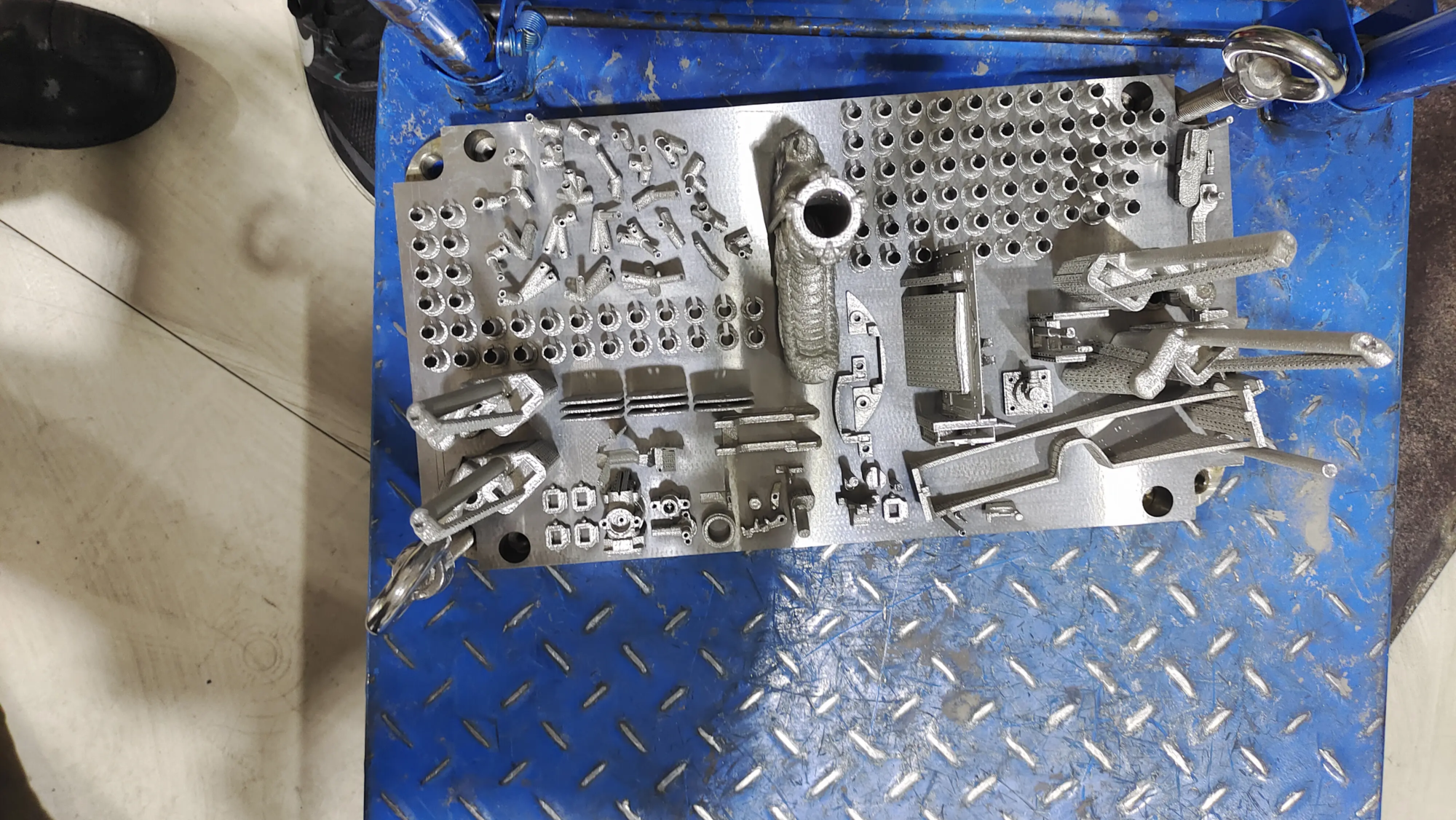

GreatLight specializes in converting complex designs into high-quality, functional prototypes and end-use parts. their Advanced SLM (Selective Laser Melting) 3D Printer Able to accurately manufacture complex metal geometries that are difficult to handle with traditional machining. They can handle a variety of materials—from durable titanium and stainless steel to lightweight aluminum—and are tailored to your project’s specific strength, weight, heat or corrosion resistance needs.

In addition to printing, GreatLight offers comprehensive One-stop post-processing service. This includes key steps such as CNC machining to achieve precise tolerances, meticulous heat treatment to optimize material properties, specialized surface treatments (polishing, electroplating, sandblasting), engraving and rigorous quality inspections. Their integrated approach ensures your custom metal parts are fully finished, rigorously tested and ready for assembly or use.

For projects that require Quick turnaround, Excellent accuracyor Sturdy metal partsexploring GreatLight’s capabilities is crucial. They excel at solving challenging prototyping requirements efficiently and cost-effectively.

in conclusion

Rainbow silk is more than just a novelty; It’s a powerful tool that democratizes vibrant, multi-color 3D printing. It enables creators to produce stunning, visually dynamic objects with relative ease, pushing the boundaries of artistic expression and design pleasure. The mesmerizing gradients are mesmerizing and show how far desktop 3D printing materials have come.

However, when your prototyping journey requires high-strength metals, micron-level precision, or integrated finishing solutions, expertise like GreatLight’s is critical. Combining dynamic creativity with professional-grade manufacturing unlocks the true potential of bringing ideas to life, whether presented in an ever-changing rainbow or resilient steel. Explore the possibilities! If you’re concerned about looks, roll up some rainbow silk. If you need strong, precise metal prototypes – huge light Ready to help you build your vision accurately and efficiently.

Frequently Asked Questions about Rainbow Silk

-

Q: Is rainbow silk more difficult to print than ordinary silk?

A: Overall it’s similar, but requires careful attention to temperature stability and retraction settings to minimize banding or bleed between colors. Start with the manufacturer’s recommended settings and fine-tune them.

-

Q: Can I control where the color changes?

Answer: You cannot directly control precise The point of change in printing; it is determined solely by the length of filament consumed. However, you can predict the effect by understanding the color transition length (check manufacturer specifications) and adjusting your model strategically.

-

Q: Will the color fade over time?

A: High-quality PLA rainbow filament should maintain its vitality indoors away from direct UV rays. For outdoor use or prolonged exposure to UV rays, UV resistance varies by brand. PETG options generally have better UV resistance than PLA.

-

Q: Is rainbow silk more expensive?

A: Yes, due to the more complex manufacturing process, the price per kilogram is usually more expensive than standard solid color PLA or PETG.

-

Q: How much filament is required for one conversion cycle?

Answer: This is what is called "transition length" Lengths vary greatly depending on the manufacturer and filament type, ranging from 1-2 meters (rapid transition) to over 10 meters (slow, gradual transition). Check product information carefully!

-

Q: Is Rainbow Silk recyclable/biodegradable?

A: It depends on the substrate. PLA-based rainbow filaments are industrially compostable (but rarely home compostable). As mixed polymer blends, dye components possible Compared with pure PLA, the recycling process is more complex. Be sure to check the manufacturer’s information.

- Q: Can GreatLight produce multi-color metal prototypes?

A: Standard SLM printing creates single-material, single-color metal parts. Achieving multiple colors on metal often involves secondary post-processing techniques such as tinting, painting or electroplating, and GreatLight also offers its core metal 3D printing and machining services. Vibrant finishes are achievable!