As a professional rapid prototyping manufacturer, Greatlight has been at the forefront of providing high-quality 3D printing services, including the production of complex metal parts. With Advanced SLM 3D printer equipment and cutting-edge production technology, Greglight has the capability to solve the problem of rapid metal parts production. In addition to technical capabilities, the company also offers one-stop post-processing and completion services to ensure customers get complete and polished products.

One of the key benefits of using Greatlime is the ability to customize materials and processing times. Most materials can be tailored to meet specific customer needs, and the company’s advanced equipment can be produced quickly. This makes Greatlight an ideal partner for businesses and individuals seeking custom precision machining services. As one of the best rapid prototype companies from China, Greatlight is committed to providing high-quality products at competitive prices.

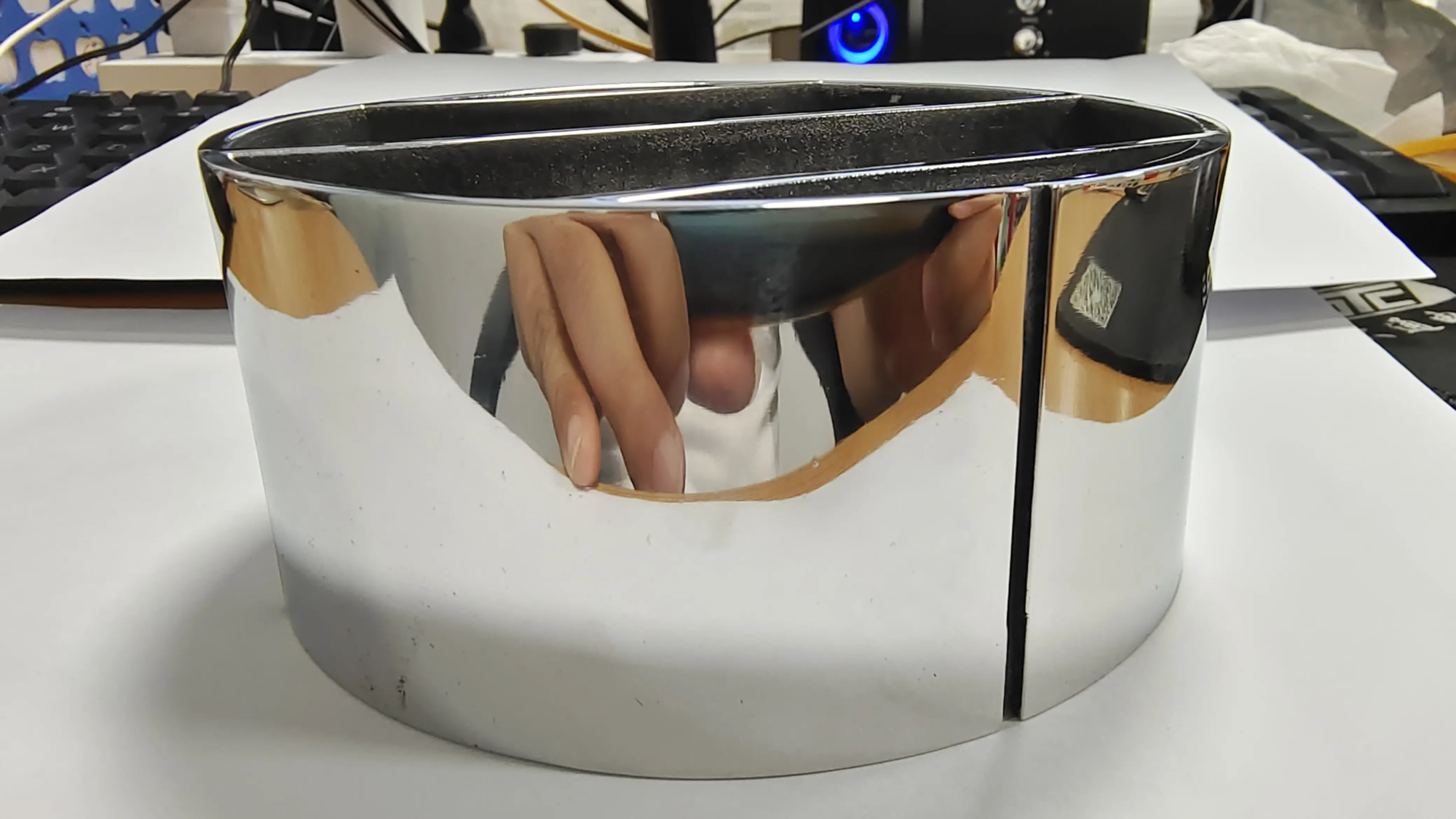

Red Hood 3D printing is a great example of the Greatlight feature. This complex design requires precision and attention to detail, making it an ideal candidate for Greatlight’s advanced 3D printing service. By leveraging its SLM 3D printer equipment, Greatlight can produce red hood 3D printing with unparalleled precision and speed. The company’s post-processing and finishing services ensure that the final product is not only functional, but also visually amazing.

Against the backdrop of 3D printing, red hood 3D printing represents a unique challenge. The complex details and complex geometric shapes of the design require a high degree of precision and technical expertise. Greatlight’s experienced team of engineers and technicians works closely with clients to ensure careful execution of all aspects of the design. From the initial design phase to the final product, Greatlight’s commitment to quality and detail is firm.

The benefits of 3D printing for Red Hood with Greatlime are numerous. The company’s advanced equipment and production technology enables rapid production, reducing lead times and increasing efficiency. In addition, Greatlight’s one-stop post-processing and finishing services simplify the production process, eliminate the need for multiple suppliers and simplify communication.

In short, the red hood 3D printing is a proof of Greatlight’s Greatlight feature as a professional rapid prototyping manufacturer. With its advanced SLM 3D printer equipment, cutting-edge production technology and commitment to quality, Greglight is the ideal partner for businesses and individuals seeking high-quality 3D printing services. Whether you are looking for custom precision machining or complex metal parts production, Greatlight has the expertise and resources to deliver excellent results.

FAQ:

Q: Which materials can be used for Red Hood 3D printing?

A: Gremply can use a variety of materials, including metals, plastics and ceramics. The company’s advanced equipment and production technology enables customization and rapid processing of most materials.

Q: What is the typical lead time for 3D printing of the red hood?

A: The lead time of Red Hat 3D printing varies by design complexity and the materials used. However, Greatlight’s advanced equipment and production technology enables rapid production, reducing lead times and increasing efficiency.

Q: Can Greatlight provide post-processing and completion services for Red Hood 3D printing?

A: Yes, Greglight offers one-stop post-processing and finishing services including polishing, painting and assembly. The company’s experienced team of engineers and technicians works closely with customers to ensure that all aspects of the design are carefully executed.

Q: How does Greatlight ensure the quality and accuracy of Red Hood 3D printing?

A: Greglight’s commitment to quality and accuracy is unwavering. The company’s advanced equipment and production technology allows precise and attention to detail, while its experienced team of engineers and technicians works closely with customers to ensure that all aspects of the design are carefully executed.

Q: Can I customize the red hood 3D printing to suit my specific needs?

A: Yes, Greglight provides custom services for red hood 3D printing. The company’s advanced equipment and production technology can quickly process most materials, and its experienced team of engineers and technicians works closely with customers to ensure that every aspect of the design is tailored to meet specific needs.

ISO 9001 Factory