Difficult in 3D printing? Conquer the filaments seep like professionals

Nothing is more frustrating than watching the 3D printer nozzle crying filaments during a critical printing process. That chaotic plastic spider web – called Exudate or string– Luin surface quality and increases post-processing time. But don’t be afraid! Whether you are an amateur or a professional, understanding and repairing filament oozing can be reached. Let’s dig into scientifically supported causes and possible solutions.

🧪 Why seepage occurs: more than just dripping water

When the melted filaments leak out of the nozzle, they will seep out Illegally squeeze out. This is a physical problem that stems from viscosity, pressure and thermodynamics:

- High viscosity fault: At too high temperatures, the filaments become too liquid, escaping gravity resistance.

- Stress accumulation: Residual pressure inside the nozzle after retracting molten plastic.

- Poor cooling: Slow cooling allows the strings to stretch between the print areas as they travel fast.

🔧 Fix: 3 Verified Strategies

1️⃣Calibration Retraction Settings

withdraw pull The filament is restored to reduce nozzle pressure. Ineffective retraction is the number one culprit in 90% of seepage cases.

- distance: Start with 0.5–1 mm of the direct drive. Bowden tubes require 3-7 mm.

- speed:45 mm/s is the best choice for most settings.

- hint: Enable "coastal" (Kura) or "wipe" (prusaslicer) Let the residual plastic be discharged before traveling.

2️⃣Optimize temperature and cooling

Each polymer has an ideal viscosity window:

- Operating temperature tower test: Print towers with layers at 5°C intervals. Check the string lines on each level to achieve the lowest temperature and have good layer adhesion.

example: PLA: 185–200°C, PETG: 220–240°C. - Improve cooling:Maximum fan speed first layer – Crucial PLA. Use auxiliary fans for abdominal muscles.

3️⃣Filament Management: Dry, Test, Replace

The moisture becomes brittle and the fiber becomes brittle, increasing leakage caused by bubbles:

- Proper drying: Use a dedicated dryer at 45–55°C at 65°C. forward print.

- Diameter check: Use calipers; > 0.05mm difference requires new filaments.

- Old/smashed nozzle?: Replace the brass nozzle every 300-500 printing hours.

⚙️ Advanced strategies for stubborn cases

- Linear progress/pressure progress: Calibrate this firmware function to dynamically control plastic flow.

- Shorten non-print travel:Slicer settings "Avoid printing parts" Minimize jumps.

- E steps calibration: Ensure the extruder pushes Exactly Required filament length.

🏁 Conclusion: Accuracy is your ultimate weapon

Defeat the filament ooze, and make the printing quality change overnight by combining science and meticulous adjustments. Apply these fixes step by step – evacuate first, then temperature, and then healthier. Remember: Consistent maintenance beat response fixed. For professionals, near-zero tolerance for flaws is not optional. If DIY troubleshooting is not a result, work with manufacturers that turn complexity into reliability.

🔎 FAQ: Exudation, simplification

Q1: Why does ooze even at low temperatures?

Shrinkage problems or moisture may be the cause. Check your settings and dry silk for 8 hours or more.

Q2: Do all the filaments seep into equally?

The viscosity of nylon, PETG and TPU oozes more easily than PLA/ABS. Higher holiday materials require slower retraction.

Q3: Will dirty nozzles cause ooze?

Absolutely. Charred residues create an unbalanced flow path. Reduce the nozzles once a month or change quarterly.

Q4: What should I do if the coastal/wiping is not cut?

reduce "Coastal number" Reduce 10% or reduce "Additional restart distance" to -0.2mm.

✨ Your high-risk printing requires zero compromise

On Greatlight, accuracy is not the goal, but our standard. As Leading Chinese rapid prototype manufacturerWe Got Amateurs’ Repairs:

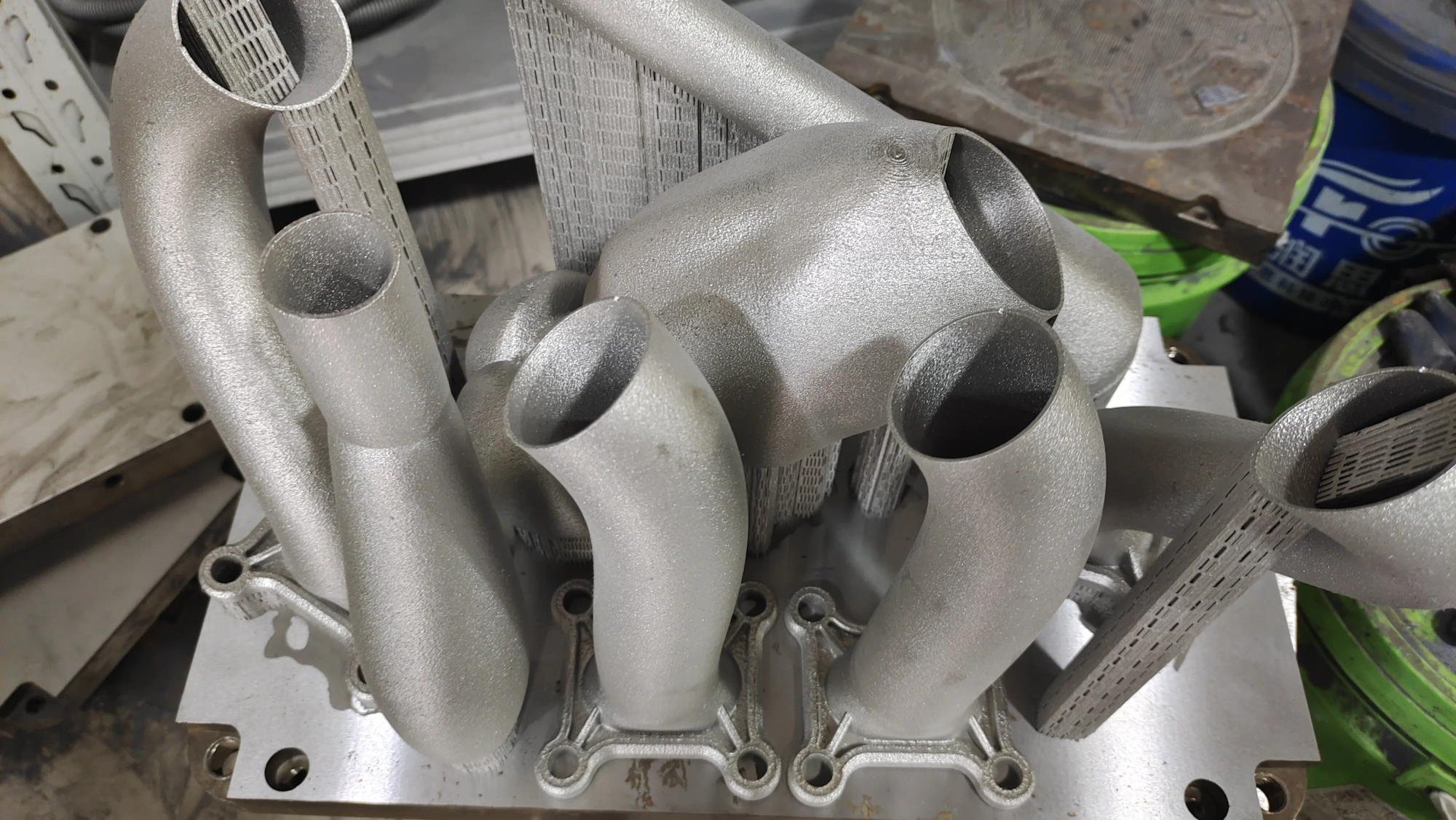

- Industrial SLM 3D Printer: Eliminate ooze, warping and strings with professional grade metals and polymers.

- One-stop post-processing:Sand blue, surface hardening and microwelding ensure perfect functional parts.

- Buy production: Prototypes are in full batch in 1-2 weeks in 48 hours, rather than troubleshooting filamentous quirks.

Forgot to guess. For CNC Moore Titanium Aviation Brackets or FDA-grade nylon tools, we will design perfectly on a large scale. Customized rapid prototyping? Get a quote today.

GRESTHILE: Printing problems match industrial solutions. 🔥