Keeping the machine in peak state: Basic Guide to 3D Printer Lubricants

Like any precision machinery, your 3D printers thrive in conventional maintenance. While cleaning nozzles and leveling the bed, the hero who is often underrated is Proper lubrication. Ignoring this simple step can lead to friction, accelerated wear, printing artifacts, annoying noise and even catastrophic component failures. Think of it as the lifeblood of smooth movement required for precise printing. At Greatlight, witnessing precise motion on our industrial SLM Metal 3D printers every day, we understand the non-negotiable role of lubrication in achieving reliable, high-quality output. Whether you are running a hobbyist FDM machine or an advanced production system, it is basic to understand and apply the right lubricant.

Why lubrication is not negotiable

Friction is the precise enemy. Inside your 3D printer, many components slide, scroll or rotate to each other:

- Linear rod/rail: Guides X, Y, and is usually the Z axis motion.

- Lead screws/rods (S): Precisely drives the Z-axis movement (sometimes an extruder).

- Bearings: Smooth rotation is achieved in motors, idles, pulleys and linear motion systems.

- Thread assembly: Found in lead nuts, couplings and certain extruder components.

No lubrication:

- Increased friction, Force the stepper motor to work harder (maybe skipped the steps).

- Wearing accelerates sharply. Shorten the life of rods, bearings and screws.

- Print quality suffers: Increased friction can lead to visible artifacts such as Z-band (horizontal line), gauze or inconsistency in squeeze due to shaft bonding.

- Rising noise levels Significant in grinding or squeaking sounds.

- Risks of epilepsy: Critical components such as lead screws can be fully grasped under high loads without lubrication.

Basic lubricant type: matching chemistry and ingredients

Not all oils and greases are equal. Using the wrong type can be harmful. Here is what you need:

White lithium oil:

- Best for: Linear rods and tracks, ball bearings (built-in/lower debris area), lead screws (especially trapezoidal type), general pivots and bushings.

- advantage: Excellent lubricity, fixed (high viscosity/"viscosity"), waterproof, long-lasting, relatively cheap. Suitable for applications with moderate loads.

- shortcoming: If applied too much or in an open environment, dust and debris will attract over time over time. For extremely high sports, it is not always ideal.

- Application Tips: Very rarely applied. Thin film is enough. Reapply regularly (every 100-150 print hours is a common starting point). Clean old grease before reapplying.

Silicone oil and grease:

- Best for: Rubber components (such as drive wheels on direct drives), plastic connectors, lead screws, where minimal chip attraction is crucial.

- advantage: Chemically inert and safe and water resistant on rubber and most plastics, it is not usually aggressively attracted to dust like lithium grease, perfect for suppressing vibration/squeaking.

- shortcoming: Lower PTFE or lithium lubricants for high load metal applications. Maximum protection of wear on linear guides is not ideal.

- Application Tips: Use very carefully on rubber surfaces for extended periods of expansion or degradation (check compatibility first). Suitable for seals and O-rings.

PTFE (Teflon) Lubricant (greas or dry spray):

- Best for: Lead screws, linear guides (especially in dusty environments when using dry ptfe), areas where minimal debris attraction are crucial. Excellent dry lubricant choice.

- advantage: PTFE provides extremely low friction (excellent friction) "slippers"), has high resistance to chemicals and heat, and usually does not attract dust/keep debris. The dry PTFE spray will leave a thin dry lubricating film.

- shortcoming: Dry sprays wear faster than grease. Grease may not be secured in place as lithium. It may be more expensive.

- Application Tips: For spray, apply gently and allow the carrier solvent to evaporate and leave the PTFE film behind. The reapply interval may be shorter than lithium grease.

- Machine oil (lightweight):

- Best for: High speed rotating bearings (motor shaft, idler), potential fine threaded rods (if specified by the manufacturer), lubrication points require very low viscosity.

- advantage: Ideal for penetrating fine gaps, very low viscosity reduces resistance to high-speed parts. It can usually be applied without disassembly.

- shortcoming: Easily extending from the vertical surface requires very frequent recoating, providing poor barrier protection, attracting dust like magnets. Not suitable for high load sliding surfaces.

- Application Tips: Rarely used. A small drop of each bearing is usually enough. Avoid access to the belt (!). Best for closed, relatively clean bearings. Use an alternative for open track/screw.

"Avoid at all costs" Lubricant:

- WD-40: Although called one "Lubricant," WD-40 is mainly Displeased in water and penetrant. Its lubricating properties are short-lived. It leaves a film that dissipates quickly, attracting a lot of dust that can dry over time and even gingival ascent mechanisms. Not suitable for long-term 3D printer lubrication. Use it only to release stuck parts and then clean and apply proper lubricant.

- Vegetables/edible oils: It will quickly turn sticky, rot, attract dirt and cause sticky mess. Avoid completely.

- Heavy Duty Vehicle Grease: Too sticky, it can cause excessive resistance and force dust into moving parts, accelerating wear.

- Lubricants with graphite: If the particles drift onto the electronic device, it may be electrically conductive and may lead to shorts.

Best practices for lubricating 3D printers

- Consult your manual: Manufacturers know best. Check the model for specific lubrication recommendations and maintenance intervals.

- Clean first: This is very important. Using isopropanol (IPA) and a paste-free wipe, thoroughly remove old lubricant, dust, debris and plastic shaving from the rod, screws and bearing surfaces before applying new lubricant. Apply lubricating oil to dirt debris and grinding components.

- Less than: Apply lubricant rare. A small piece has a long way to go. For grease, aim for thin, almost translucent movies. For oil, a drop is usually enough to hold the bearing. Excess lubricant acts as a dirt magnet and creates resistance.

- Apply correctly: Place the lubricant along the length of the rod or the screw thread. Move the carriage or manually turn the screws to evenly distribute the lubricant through the bearing block or nut. For bearings, if possible, apply directly to the runway.

- Frequency is key: Don’t wait to scream. Establish an active maintenance schedule. How long depends on the strength of use (print hours), environment (dust level), and lubricant type. As a baseline, check the rods and screws monthly. Relubricate the rod/bearing every 100-300 printing hours and adjust the lead screw every 50-150 hours according to observation and lubricant type.

- Re-clean regularly: Even if it is well lubricated, dust will accumulate. Schedule regular deep cleaning (if possible) to remove contaminated lubricant and debris and then relubricate.

Conclusion: Accurately required care

Investing in the right lubricant and applying it correctly is not only maintenance; it is an investment in the life of 3D printers, and ultimately the quality of printed parts. Friction is a stealth enemy that quietly reduces performance. It is crucial to understand the role of white lithium, silicone, PTFE and light oil no To use (such as WD-40!), you will equip yourself to keep the machine running smoothly.

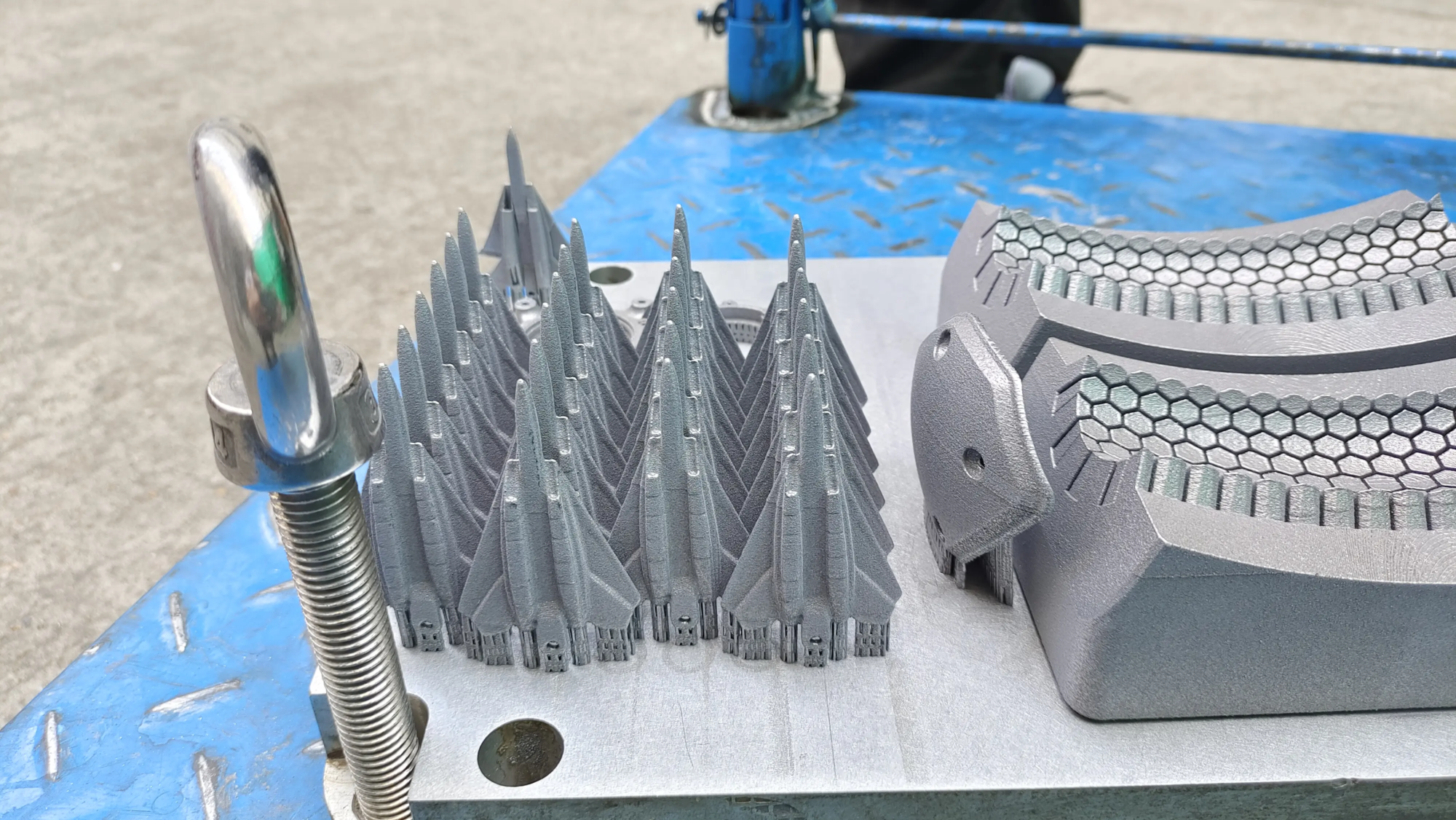

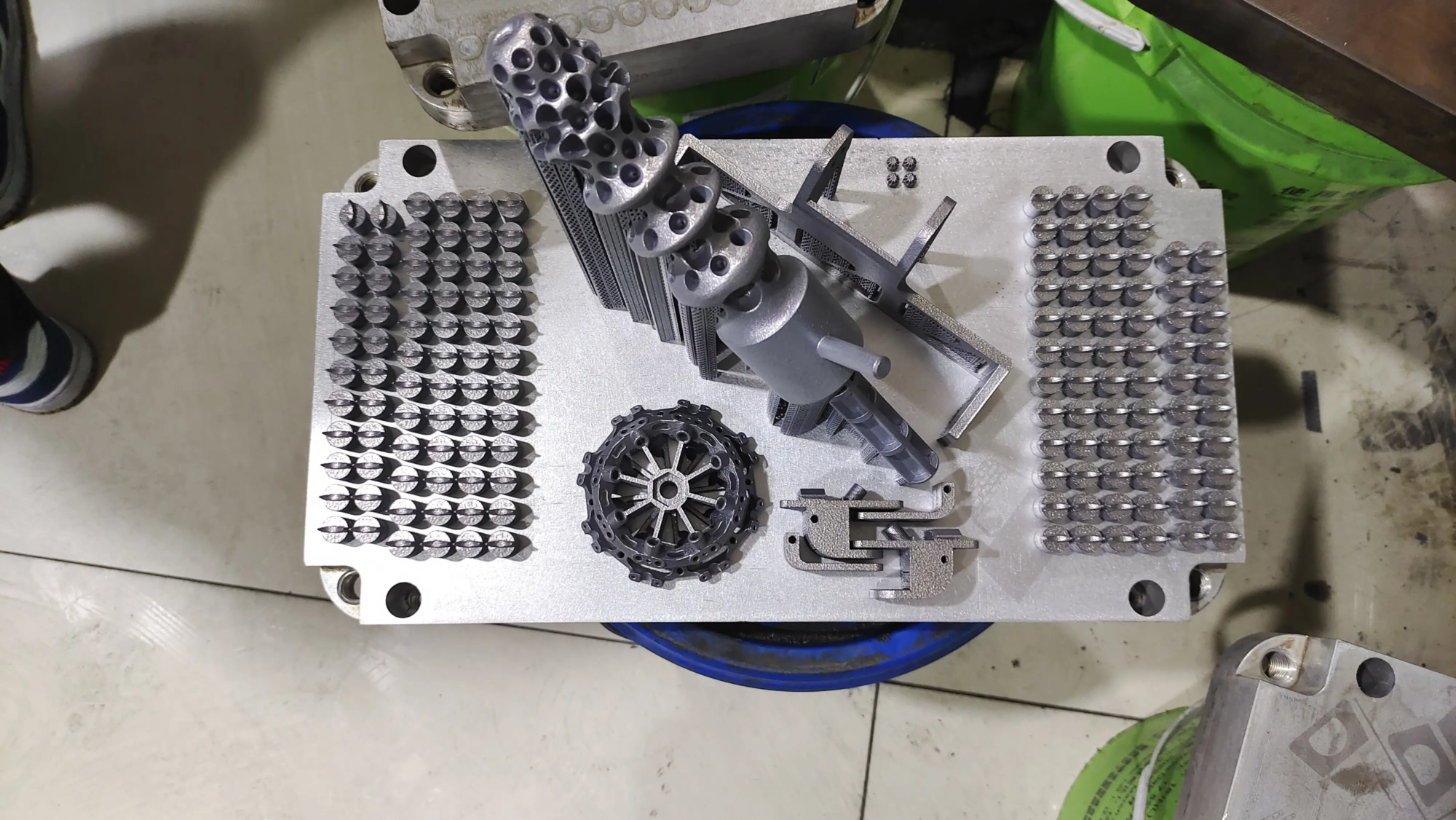

At Greatlight, our commitment to accuracy is more than just operating advanced SLM Metal 3D printers. We carefully maintain the equipment to ensure that every custom precise prototype and production section meets strict standards. Whether your project requires the complex strength of metal printed components or expert post-processing to achieve the perfect finish, our team leverages state-of-the-art technology and rigorous processes to deliver reliable high-quality results quickly. Don’t let mechanical friction become a bottleneck in innovation or production. Keep your printer lubricated correctly and when you need unrivalled accuracy in metal parts, trust Greatlame can provide cutting-edge rapid prototyping solutions.

FAQ: 3D printer lubrication

Q1: How often should I lubricate the printer?

A: No answer. This depends to a large extent on:

- usage: Print 24/7? Lubrication frequency is higher (e.g. every 1-2 weeks). Print occasionally? Every 1-2 months is enough.

- environment: Dustworthy workshops require more frequent cleaning and lubrication.

- Lubricants used: PTFE dry moisturizer may be reapplied more frequently than viscous lithium grease.

- Printer design: The open frame is dirtier than the closed printer.

- Start with the manufacturer’s guide. listen and watch: Squeaking, visible dirt buildup on the pole/line or increased print artifacts (such as Z-band) are clear warnings. A good benchmark is examine Rod/screw lubricate linear bearings every 100-200 hours per month, lead screw/bearing every 50-150 hours.

Q2: Can I use GM grease on a 3D printer?

A: Generally speaking, Not recommended. Many cars are too grease (high NLGI rating) for relatively low loads and high accuracy of 3D printer motion. They can over-drag the stepper motor and it will be easier to catch dust/debris. Stick to the recommended lightweight lithium, PTFE or silicone water grease, designed for lightweight machinery or precision instruments.

Question 3: WD-40 used to work when my Leadscrew got stuck. Why can’t I use it regularly?

A: WD-40 is great Penetration and displacementso release the stuck part. But, Not a special lubricant. Its residual film provides very temporary lubrication, evaporate/dry, and becomes viscous, which subsequently attracts a lot of dust and debris, just like grinding paste on the component. Use it only as a one-time solution to release the deducted parts, then Clean thoroughly and apply the correct lubricant.

Question 4: I applied grease, but now my print shows more Z-splash? What’s wrong?

A: This usually points to Overlubrication. Excessive grease can create hydraulic resistance and uneven resistance on the Z-axis lead screw (or linear rod), causing the stepper motor to struggle and move inconsistently. Solution: Carefully disassemble and completely disassemble Clean Z-axis screws, nuts and bearings with IPA. Reapply for a Minimumfilms with correct lubricants (such as PTFE grease or light lithium).

Q5: My printer has linear guides, not rods. Does it require different lubrication?

A: Linear guide rails are usually more robust and sealed than open rods/bearings. But they still need lubrication. High-quality linear tracks usually pre-lubricate specific, durable grease. refer to Strictly point to the railway manufacturer’s documents For maintenance intervals and recommended grease types to avoid damage to the seal. Adding incompatible or excessive lubricant can degrade seals and performance.

Question 6: How do I know my bearings need to be replaced and not just lubricated?

A: Lubrication will not repair physically worn bearings. Logo includes:

- Stain or rumble Even after thorough cleaning and lubrication.

- Visible game or swing When moved manually, in the bearing housing.

- Serious, consistent prints Cleaning/lubrication cannot be resolved.

- Bind or stick This prevents flow.

If these symptoms persist after maintenance, they may need to be replaced.