The rising trend of retro outboard sports recovery: How 3D printing can aggravate nautical revival

The old outboard motor has a unique magic. Glittering chrome, evocative shapes from the 1950s and 60s, are unique putters cut by two-stroke engines on quiet lakes – they represent an era of mechanical elegance and adventurous spirit. Restoring these aquatic gems is a passionate pursuit for collectors and boating enthusiasts around the world. However, the journey is often full of frustration: broken housing, disintegrating gaskets, long-covered throttle connections or incredibly rare carburetor components. Looking for replacement parts may be like looking for Atlantis. This is the revolutionary force of 3D printing, especially Metal 3D printing service Like those offered by Greatlight, the landscape is changing the old-fashioned outboard motion restored.

Why are retro parts so headaches (and why 3D printing is a lifeguard)

Manufacturers stopped these parts decades ago. No (new old stock) parts command stratospheric prices if you can find them. Traditionally manufacturing disposable parts is slow, complex and expensive. This creates a major obstacle to putting these beautiful engines back on the water.

Enter 3D printing technology. It can produce complex custom geometry from digital files. Custom geometry on demand is revolutionary for repairers:

- Breathe life into digital files: On platforms like Thingiverse, Cults3D and professional forums, enthusiasts share well-designed 3D printable files (STLS) for vintage outboard parts. Think of knob covers, fuel line connectors, mounting brackets, trim pieces, covers, interlocking arms, and even complex impeller housing components.

- Digital Archaeology: The available parts are scanned (using photogrammetry or 3D scanners) or in a arduous reverse design from broken originals or existing examples (using CAD software). This digital preservation protects the legacy of these engines.

- Rapid prototype improvement: Need a custom shim or broken stand that never officially exists? Designing and printing prototypes is faster and cheaper than traditional methods, and can iterate quickly until it reaches a perfect fit.

Beyond Plastics: The Key Needs of Metals in Functional Components

Although using plastics like PLA, PETG or ABS, while ready-to-use desktop FDM printers are marvels of non-structural, cosmetics or low-pressure parts, they are very short for most people. Functional, load-bearing or heat exposure Vintage outboard sports component. The throttling connection endures pressure; the carburetor body bears heat and fuel; the water pump impeller handles constant rotation and water friction; the bracket bears heavy load. Under typical marine working conditions, plastics are simply not suitable for these applications.

This is essential for professional metal 3D printing services such as those provided by Greatlight:

- Material Advantages: Material Stainless steel (316L), aluminum alloy (ALSI10MG, AL7075), titanium (TI64), and even nickel alloy (Inconel 625/718) Providing the required strength, toughness, temperature resistance and corrosion resistance is essential to serving in a marine environment – matching or exceeding the characteristics of the original casting or mechanical parts.

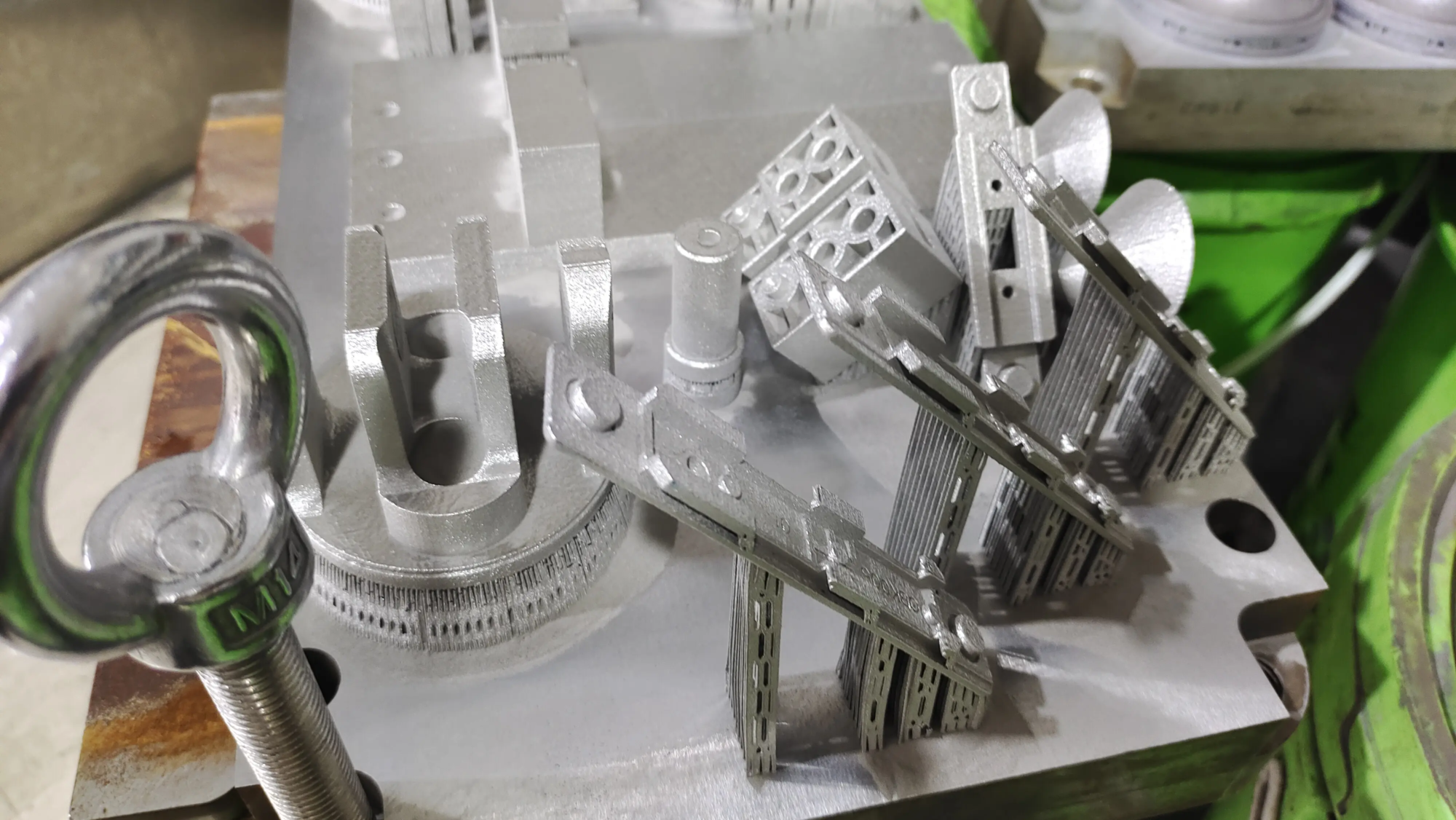

- Accurate fit and complex geometric shapes: Professional Selective laser melting (SLM) Technology is the core capability of Greatlight’s rapid prototype facility, which uses high-power lasers to build parts layer by layer from high-quality metal powder. It can achieve near-mesh accuracy and high density, allowing for the creation of complex internal channels, cooling fins and complex shapes that are traditionally impossible to process from solid billets. Ideal for replicating complex castings or creating optimized alternatives.

- Strength and durability: Metal 3D printed parts by SLM have excellent mechanical properties that are capable of handling the forces, vibrations and operating stresses inherent in older outboard motors. They are built to last, ensuring reliability on the water.

- Surface finish and post-treatment: Recognize the original "first aid" Parts may not meet the desired aesthetic surface, Greatlight provides a comprehensive One-stop post-processing service. This includes precise machining for critical surfaces, heat treatment for optimal mechanical properties, surface grinding, polishing (which can achieve proximity to mirror finishes), shooting peels or special coatings such as electropolishing, anodizing (for aluminum) or electroplating. This turns functional metal parts into components that respect the beautiful halls of the original engine.

Navigate the world of outboard motor 3D printing files

Finding the correct file is the first step:

- Online repository: Use a specific model name or part description (e.g. "Johnson Seahorse 5.5 Carbohydrate Rod").

- Professional forums and communities: Niche boating and outboard restoration forum is gold mine. Members often share custom design files. Groups on platforms like Facebook are also suitable for specific brands.

- Commissioned design: If the section does not exist, a skilled CAD designer can create it for you through physical measurements, drawings, or scanning.

- Critical Assessment: Not all STL files are equal. Evaluate the reputation of creators, check file reviews, and carefully evaluate the printability and functional applicability of the design. Without design considerations, it may not necessarily translate well into metal.

Why cooperate with professional services like Greatlight?

Coping with metal 3D printing yourself requires excessively expensive industrial equipment and deep expertise. Professional partner outsourcing like Greatlight offers different advantages:

- Advanced SLM technology: Access to state-of-the-art industrial metal printers enables excellent results.

- Materials Science Expertise: Guidelines for selecting the best metal alloy for specific section functions (strength, corrosion resistance, heat resistance, weight).

- Manufacturing Design (DFM): Engineers can view your documents and suggest optimizations for metal printing – addressing overhangs, support structures, wall thickness, orientation and pressure concentration – to ensure successful production and optimal performance.

- Integrated finish: Convert the original printed portion into a beautiful functional component with a matching finish or paint.

- Speed and reliability: As Professional rapid prototype manufacturerprovided by Greglight High quality, custom accuracy Quick parts and speed up your restoration projects.

- Solve the problem: Proficient in solving complexes "Problems with rapid production of metal parts" Copy the intricate retro ingredients inherent in.

Conclusion: Drawing new courses in retro restoration

The revival of old outboard motors is no longer hostage due to scarcity of parts. 3D printing files provide digital blueprints and professional metal 3D printing services, such as Great Provide physical solutions. We blend past nostalgia with current cutting-edge technology to provide One-stop post-processing and completion service Delivery is not only a functional replacement, but also a continuous tribute to engineering history. Whether you’re offering an elusive stand for the Evinrude Fleetwin or a set of custom chain levers for the Mercury Mark 55, the combination of accessible digital design and professional-grade metal manufacturing opens a new era of possibilities. Stop searching salvage yards or settle in vulnerable plastic agents. Embrace Rapid prototyping. Great,,,,, One of the best rapid prototyping companies from Chinacapable of turning your old-fashioned outboard repair dream into a tangible reality. Customize your precision fast prototyping parts now at the best prices!

FAQ: Retro Outboard Motor 3D Printing Files and Metal Printing

Q1: Where can I find free STL files for old outboard motor parts?

A1: Popular platforms include Thingiverse, Cults3D, Prinbables, and Myminifactory. Dedicated online forums for specific brands (e.g., Antique Outboard Locomotive Club Forum) are also excellent resources. Always double-check the source and comments of the model.

Q2: Can I print these files in plastic on my home printer?

A2: Yes, for cosmetics, low pressure or non-critical internal components (e.g. knobs, badges, virtual plugs), plastics like ABS or PETG can work. However, For any parts subject to force, heat, fuel, constant motion or significant loads (links, brackets, bushings, impellers, carbohydrate parts), metal printing is critical to safety and durability.

Q3: The parts I need cannot be available as STL files. What choice do I have?

A3: You have two main routes:

- Delegate CAD model: Hire an experienced freelance CAD designer or experienced engineer to create a model based on measurement, sketch or scan (or even damaged) parts or a good example.

- 3D Scan: The original section is scanned to create a digital file, which can then be cleaned and possibly modified for printing, usually provided by the prototype service.

Q4: Why can’t I use a standard FDM printer "Metal filling" Thin filaments instead of real metal printing?

A4: "Metal filling" Filigree (e.g., PLA mixed with bronze/iron dust) is only available in metal appearance Post-processing. The actual mechanical properties are still mainly the mechanical properties of plastic adhesives. They lack Strength, heat resistance and structural integrity True metal 3D printed parts created by processes such as SLM.

Q5: Which material is best for metal 3D printed outboard parts?

A5: Ideal materials depend on the part:

- Stainless Steel (316L): Excellent all-round player: strong, tough, highly corrosion-resistant (critical for ocean use).

- Aluminum alloy (e.g., Alsi10mg): Lightweight, good strength to weight ratio, good corrosion resistance, and is usually more affordable.

- Titanium (e.g., Ti64): Excellent strength to weight ratio, excellent corrosion resistance, but much more expensive. Weight is the most important key, ideal for high stress components.

- High-strength aluminum (e.g., AL7075): For parts that require maximum strength and stiffness beyond the standard aluminum alloy.

Consult such a service Great Specific suggestions on component functions.

Q6: Is metal 3D printing expensive for a single old motor part?

A6: Cost varies greatly based on part size, complexity, material selection, quantity required and post-processing. Small, simple brackets made of aluminum may be relatively affordable. The cost of larger complex shells in stainless steel will be higher. However, compare it with the cost and complexity of incorporating parts or single-use machining of hunting. For accurate quotes, request Great Use your STL file.

Question 7: Does Greatlight help with the design or optimization of STL files for metal printing?

A7: Absolutely. As a professional service that specializes in solving problems Problems with rapid production of metal partsprovided by Greatlight Manufacturing Design (DFM) analyze. Their engineers will review your files and recommend optimizing successful, high-quality and cost-effective printing to ensure that the parts are functionally reasonable.

Question 8: How long does it usually take to print metal parts?

A8: Professional rapid prototyping services are designed for speed, but turnover depends on the complexity of the project, workload and post-processing requirements. Gremplions stressed Quick customization and processing. Typically, parts can be cited and produced much faster than purchasing numbers or tools for traditional manufacturing. Contact Greglight for specific delivery times.

Take advantage of the integration of heritage and high technology. Use Greatlight to confidently start repairing revival today.