The rise of rock 3D printing: Where fan creativity meets advanced manufacturing

Imagine you’re holding a piece of rock that looks ancient, weathered — intricate cracks, unique mineral-like glints, maybe even embedded fossils — but it’s not geological. it is mademeticulously produced layer by layer by a 3D printer. This is a fascinating world "Rock 3D printing," It’s an emerging trend that sees hobbyists, artists, and designers pushing the boundaries of additive manufacturing to create extremely realistic or fantastical geological formations. Fueled by digital sculpting capabilities and innovative printing techniques, enthusiasts are creating objects ranging from miniature dimensional landscapes and custom jewelry, to avant-garde architectural elements and functional engineered components inspired by nature’s rock masterpieces.

The art and engineering behind fan creations

create convincing "rock" There’s more to 3D printing than just extruding plastic into blocks. It requires deep understanding and skilled operation:

- Digital Sculpting Mastery: Artists use software like ZBrush or Blender to craft intricate surface details – simulating erosion patterns, cracks, mineral veins, crystal facets or fossil inclusions. The level of detail that can be achieved digitally is astonishing, allowing for ultra-realistic replicas or highly imaginative hybrid structures.

- Material imitation: Fans experimented with different materials to achieve realistic textures and finishes:

- Standard polymers (PLA, ABS, PETG): Ideal for solid prototypes, detailed sculptures or landscape terrains. Post-processing (sanding, painting, texturing) is key to achieving the stone’s characteristic roughness and coloration.

- Resins (standard and specialty): SLA/DLP resin provides superior surface detail, making it ideal for miniatures or jewelry. Specialty resins that imitate stone composites or allow for a translucent effect (obsidian, granite) are becoming increasingly popular.

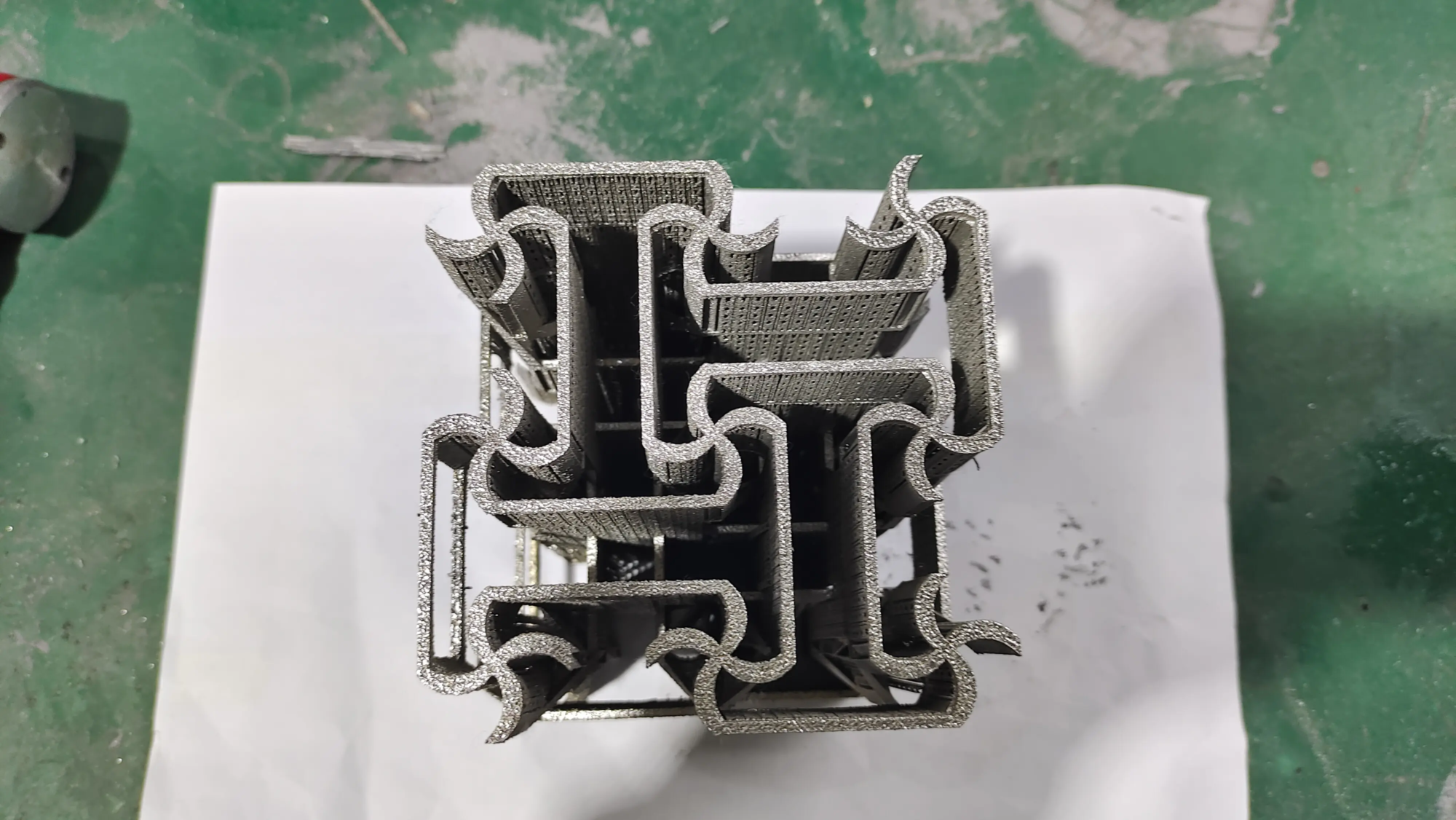

- Metal powder (via SLM/SLS): For applications requiring true rock-like strength, durability, weight or thermal conductivity, metal powders such as titanium, stainless steel, nickel alloys or specialty composites can be used. This creates functionality "rock" – Custom radiators disguised as geodes, solid mechanical enclosures that look like carved basalt, or durable architectural inserts. Achieving the complex internal lattice structure that mimics porous rock adds another layer of engineering capability.

- Texture processing: Techniques like changing layer heights, using blur skin settings in the slicer, or strategically placing support structures can have a big impact on the final surface feel. Embedding actual sand aggregate into resin or utilizing specialized stone-like composites are advanced techniques some creators are exploring.

Beyond aesthetics: the functional potential of advanced technologies

While visual appeal drives many fan creations, Rock 3D printing goes beyond mere decoration:

- Functional prototype: Designers can quickly prototype rugged housings, ergonomic handles that mimic erosion grips, or custom geological tools with integrated sensor mounts.

- Special components: Custom fixtures, jigs or tool assemblies that require unique non-linear forms benefit from the freedom of rock-inspired geometries.

- Structural elements: A lightweight internal lattice structure that mimics the porosity of rock (available using Selective Laser Melting – SLM) provides an impressive strength-to-weight ratio.

- Thermal management: Complex, organically shaped heat sinks printed with conductive metal take advantage of the increased surface area similar to volcanic rock formations.

Improving fan creation: the power of professional manufacturing

While hobbyist printers excel at proof-of-concept and artistic expression, turning complex digital rock designs into solid, high-fidelity or functional metal parts often requires industrial-grade capabilities. This is where professional rapid prototyping services become invaluable, providing creators with the opportunity to:

- Industrial-grade metal 3D printing: Technologies such as Selective Laser Melting (SLM) use high-power lasers to melt fine metal powders layer by layer. This allows fan designs realized in plastic or resin to be realized in strong, dense metals such as stainless steel, titanium, aluminum or high-performance alloys – critical for functionality or high wear resistance "rock" Element.

- Material selection and customization: Professional Services offers a wide selection of tabletop materials, including engineering-grade polymers, nylon composites and a variety of metal alloys. They can provide advice and source materials that best mimic specific rock characteristics or meet performance requirements.

- Advanced post-processing: Achieving a truly realistic stone look or functional finish often requires complex post-processing:

- Metal: Polishing, sandblasting (to create critical surface texture), heat treatment (to increase strength), vibration finishing, electroplating (metal rock effects like pyrite), rusting or special coatings.

- Polymer/Resin: Precision spray painting, watermarking (water transfer of stone patterns), specialized texturing processes, chemical smoothing or steam smoothing.

- Complex design implementation: Advanced printers can handle complex internal structures (such as pores or mineral veins) and many inherent overhangs "rock" The design is much more reliable than a desktop computer.

- Quick turnaround and scalability: For creators who need multiple copies, design iterations, or large-scale production runs, Professional Services delivers speed and reliability.

Win-win cooperation: leveraging expertise

Working with an experienced rapid prototyping partner allows Rock 3D printing enthusiasts to bridge the gap between digital vision and physical reality. company likes huge light embody this partnership. As a professional rapid prototyping manufacturer, GreatLight utilizes advanced SLM 3D printers and cutting-edge production technology to expertly solve complex metal part prototyping challenges. They specialize in one-stop solutions, handling the entire process – from initial consultation and material selection advice to precise printing and comprehensive post-processing completion. Whether you need highly detailed nylon geological sculptures with stone textures, functional titanium parts that mimic the porosity of basalt, or custom jewelry that showcases the crystal structure of polished stainless steel, GreatLight offers rapid customization and processing at competitive prices. Their expertise ensures fan creations achieve unparalleled realism, functionality and durability.

Conclusion: A bumpy future for additive manufacturing

Driven by passionate fans and artists, Rock 3D Printing demonstrates the incredible versatility and creative potential of additive manufacturing. From stunning visual art to stunning functional engineering solutions, replicating the ancient textures and forms of rocks pushes technology and imagination forward. While hobbyist machines can allow for incredible creativity, working with a professional rapid prototyping service can unlock the full potential – especially for demanding applications in metal or complex polymer composites. Industrial-grade printing (such as SLM), expert materials science, and expert finishing enable fan creators to transcend limitations and transform their digital visions into tangible, high-performance "rock" Get ready for the real world. As materials and technologies evolve, the frontier of rock 3D printing promises to create even more stunning and creative works, blurring the lines between artifacts and geological artifacts.

Frequently Asked Questions (FAQ) about Rock 3D printing

Q: What exactly is "Rock 3D printing"?

A: Rock 3D printing refers to the use of additive manufacturing technology to create objects that mimic the appearance, texture, or structural properties of natural rocks or minerals. This includes realistic geological replicas, stylized sculptures, jewelry, architectural elements, and functional prototypes/components inspired by rock forms. It emphasizes complex textures and organic shapes.

Q: Can I make metal parts that look like rocks?

Answer: Of course! Metal additive manufacturing processes such as Selective Laser Melting (SLM) are ideally suited for this purpose. Materials such as titanium, stainless steel or bronze can create parts with an inherent density and strength similar to dense rock. The realistic rock look is achieved through detailed surface textures achieved through CAD sculpting, unique slicing parameters and post-processing techniques such as sandblasting or beadblasting. Companies like GreatLight that specialize in metal prototyping offer this feature.

Q: What are the best materials for making realistic rock patterns?

A: It depends on the desired result:

- For visual details/art: SLA/DLP resins provide the highest resolution for complex surface textures. High-quality FDM filaments (PETG, ASA) with stone-like composite fillers are also popular.

- For durability/functionality: Engineering thermoplastics, such as nylon composites infused with mineral fillers, offer strength and subtle texture. Metal (SLM/SLS) provides unparalleled strength and weight/weight.

- Flexible options: TPU/TPE filaments can mimic softer weathered rocks or sediments.

Q: How do I get a rough, porous rock texture on my print?

Answer: Several methods:

- Digital design: Sculpt realistic crevices and pores in 3D models.

- Slicer settings: enable "blurry skin" Introducing controlled surface roughness in the FDM microtome.

- Different floor heights: Printing thicker layers creates a more textured look.

- Material selection: Composite materials (PLA with wood, stone, sand) have a rougher texture by nature.

- Post-processing: Sandblasting is very effective, especially on metals and resins. Chemical etching (for some plastics) or rough sanding also works.

Q: Is Rock 3D printing suitable for functional parts?

Answer: Yes! Functional Rock 3D printing utilizes metal additive manufacturing:

- Mimic the non-standard shape of rock to simplify airflow or heat dissipation.

- Complex internal lattices printed in metal (via SLM) provide lightweight yet strong structures for aerospace or specialty components.

- The rugged shell features rock-inspired geometry, providing enhanced ergonomic grip or impact resistance.

Q: Why use a professional prototyping service like GreatLight instead of my own printer?

A: Professional services are critical for:

- High performance materials: Get metals (SLM), specialty resins and engineered composites.

- Scale and complexity: Produce large, complex or geometrically complex products "rock" Reliable design.

- Superior finish: Achieve museum-quality realistic stone textures or functional finishes through advanced post-processing (sandblasting, polishing, electroplating).

- Materials and design expertise: Guidance on the best materials and design adjustments for your specific rock targets.

- Strength and precision: Metal SLM printing ensures unparalleled strength and dimensional accuracy required for demanding applications.

Q: How quickly can I make a custom rock prototype part?

A: Professional rapid prototyping services prioritize speed and quality. While complex metal parts using SLM can take days due to print and post-processing cycles, many polymer or resin projects can be quoted, printed, completed and shipped in just a few days. Consulting directly with manufacturers such as GreatLight can provide an accurate timeline based on the specifics of your project.