Unleashing the Waves: Your Final Guide to the Perfect Spray of 3D Printing

The iconic wave is a little turtle Pokémon, strabismus and powerful water cannon that holds a special place in the hearts of fans around the world. What better way to celebrate this beloved character than to 3D printing? Whether you are an experienced maker or a Pokémon enthusiast dip your toes into the 3D printing world, making your own Squirtle models is an incredible project. This guide delves into the process, covering everything from design preparation to perfect finishing to ensure your Squirtle Squad is legendary.

The attraction of 3D printed waves

The Squirtle’s compact, round shape, different shells and bulky tail make it an excellent candidate for FDM (fiber) and resin 3D printing. Creating a physical spray model allows for the ultimate customization – paint it into a shiny variant with classic blue, expanding it into an impact, or even designing dynamic poses. Apart from interesting display pieces, this is a practical way to hone your 3D printing and finishing skills. Plus, custom 3D printed ammunition is a truly unique gift that can showcase technical skills and personal passion.

Your step-by-step celebrity printing journey

-

Purchase the perfect digital blueprint:

- First of all, good source of reputable: Start with trusted platforms like Thingiverse, Cults3D or myminifactory. search "Squirtle Stl" And look for models with high ratings, detailed previews and positive user reviews. Pay attention to potential copyright issues; prioritize models shared by creators to acknowledge fan art or non-commercial use.

- Model evaluation is key: Check the model carefully. Looking for:

- Wattightness: The model should not have holes or blanks in its mesh (a "Non-manifold" net). Use software such as Meshmixer or Windows 3D Builder’s automatic repair tool to solve the problem.

- Level of details: Does this model accurately capture Squirtle’s functionality? High-detailed models are more suitable for resins, while FDM benefits from a slightly simplified version.

- Posing with static: Choose between dynamic action poses (more support may be required) or static stable poses for easy printing.

- Pre-supported considerations: Some models include pre-support optimized for resin printing. Although convenient, they may not be suitable for your specific printer/resin. Make a critical assessment of them or prepare to generate your own.

-

Model Preparation and Slicing – Setting Successfully:

- Select a slicer: Use reliable slice software such as Ultimaker Cura (excellent for FDM), Prusaslicer (FDM and resin) or Lychee Slicer/Chitubox (specially for resin).

- Direction is important (especially resin):

- Tilt the model backwards (approximately 45 degrees) to minimize cross-sectional area of each layer, reducing suction and risk of layer separation or failure of prints.

- If possible, point the tail upwards.

- Avoid large planar areas parallel to the build board to minimize visible layer lines on the key surface.

- Master the support structure: This is very important.

- Resin Printing: Automatically generated support is a starting point. Manually strengthen key areas: The tip of the tail, the bottom of the foot, the end of the nose, and the edge of the arm/shell. Make sure the support contacts are on less obvious surfaces. Use media support in terms of structural areas and light support for more detailed details.

- FDM Printing: Spanning tree (organic) or linear support. Focus on arms, chin and potential tail. Adjust support density (15-20% usually works well for FDM) and Z-Distance for easy removal. Enable edges to prevent warping, especially with materials similar to abdominal muscles.

- Dial in printer settings:

- Resin: Layer height (0.03mm-0.05mm details), exposure time (calibration your Resin/printer! ), lift speed (slower = more reliable), back-overlapping (for smoother curves).

- FDM: Layer height (0.1mm -0.2mm), printing temperature (material specific), printing speed (mass of 40-60mm/s), cooling (100% fan after the first layer), retraction (tune to minimize strings). It is recommended to use a shell for ABS.

-

Material Selection – Balances the appearance, feel and function:

- Resin (unparalleled details and smoothness):

- Standard resin: Perfect for smooth, high-detailed characters preparing for painting. Affordable, but can be vulnerable.

- ABS-like resin: Provides greater durability and flexibility (reduces the risk of capturing the tail), slightly hard grinding, which is good for functional printing.

- Washable resin: Simplify cleaning, but usually sacrifices durability and surface quality slightly. Ideal for beginners.

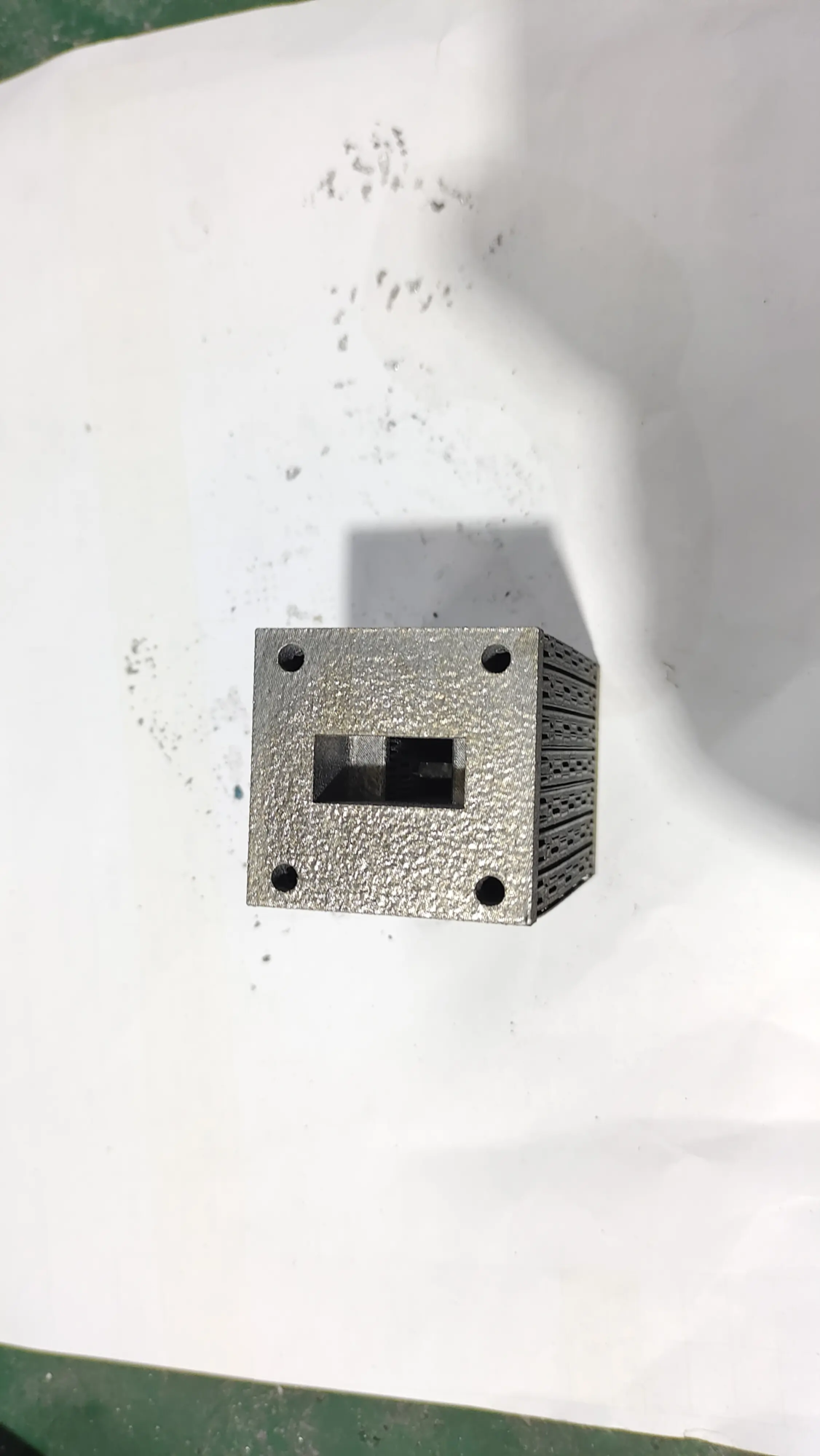

- Ceramic-based gypsum: (Binder jets from professional services like Begright (such as Greatlight)) provide a unique stone-like aesthetic. Excellent surface, complex geometric treatment. Need to be infiltrated.

- FDM filaments (strength and ease of use):

- PLA: First choice. Easy to print, width range (find the perfect blue blue!), biodegradable. Best for displaying models. Can be polished/painted.

- PETG: More durable and heat-resistant than PLA, slightly flexible. Suitable for prints that may be processed frequently. Need for higher temperatures and better partial cooling.

- ASA/ABS: High durability and temperature resistance. Ideal for outdoor use. Fences, heated beds and good ventilation are required due to smoke.

- Resin (unparalleled details and smoothness):

-

Execution of Prints – Patience is a virtue:

- Resin:

- Carefully tidy up the construction board.

- Filter the resin before pouring into the bucket.

- Monitor the first few layers closely for adhesion.

- Avoid interference or vibration during printing.

- Make sure to have adequate ventilation or wear a respirator with organic steam cartridges.

- FDM:

- Make sure the build plate is completely level and clean (using isopropanol or glue stick).

- Check for proper first layer of adhesion – "extrusion" very good!

- Listen to abnormal sounds indicating squeezing problems or collisions.

- There are no drafts to keep a stable environment.

- Service Provider Considerations: If complex details, large-scale or demanding materials such as metal or ceramic adhesives (such as professional finishes that can only be achieved with SLM or Binder jet technology) are beyond your setup, then working with the professional services of Greatlight (Greatlight) ensures the best results. Our industrial grade SLM printers handle complex geometry in metals, while our adhesive sprays produce a unique gypsum-based aesthetic, all with strict quality control.

- Resin:

- Post-processing – Convert printing to perfection:

- clean:

- Resin: Gently delete the model. Wash thoroughly in isopropanol (2 bathtubs recommended) in wash table (or manually with a soft brush). Delete support back washing. Completely healed under UV light (follow the resin guide).

- FDM: Carefully remove the support using a rinse cutting machine, pliers or hobby knife. Clean up the packed/raft.

- Grinding and filling: Grinding is essential for preparing the finish of paint, especially for FDM. Gradually use finer sandpaper (start ~120 sandpaper, finish 400-600+). Fill the layer lines/gap with fill primer, putty (Milliput, Bondo Spot Putty) or Ca glue. After filling, sand again. Resin printing usually requires minimal grinding, with the focus on supporting the removal point.

- painting: Raise your small scale with colors!

- Prime: Use spray or brush primer (gray or white) for even coverage and improved paint adhesion.

- Basic Coat: Acrylic paints (e.g., Vallejo, Citadel) are user-friendly. Apply a thin layer. Capture Squirtle’s signature blue body and light tan shell base.

- Details: Use a fine brush for eye, mouth and shell pattern. Wash/shadow adds depth to the grooves and primer of the shell. Optional gloss varnish for the eyes and high gloss water effects. The matte varnish looks natural elsewhere.

- Professionally completed: Services like Greatlight offer advanced post-processing: precise sand blue for uniform textures, expert hand-match/polishing, seamless painting, with durable finishes, plating (for metal effects (such as armored waves)!), and a clear coating to protect UV light. Ideal for high value committees or batch production.

- clean:

Conclusion: Order your own team!

3D Printing Squirtle blends nostalgia, creativity and technical skills into a unique and satisfying project. By carefully managing each stage – from model selection and slicing to choosing the right material and mastering the key steps of demolition and post-processing – you can create an amazing miniature will for your favorite water-type starter. Prepare for trial and error, embrace the learning process, and use professional manufacturing resources without hesitation when challenging or seeking museum quality finishes.

Ready to bring your ultimate 3D printed Pokémon vision to life? Greatlight specializes in transforming complex digital design into perfect physical reality. From high-detailed resin and durable FDM printing to premium metal and ceramic adhesive jets for truly unique finishes, our fast prototype expertise and comprehensive after-processing service ensure your ocean waves (or any custom project) exceed expectations. Contact Greatlight now to get a quote and experience the difference in professional accuracy!

FAQ (FAQ)

-

Where can I find free, reliable and secure Squirtle STL files?

- Focus on well-known communities such as Thingiverse, Prinbables or Cults3d. Priority tagged as "Fan Art" And marked as Personal, non-commercial use only. Always check model comments and creator information. Avoid suspicious downloads.

-

Why is my resin ammo printing failed/failed to stick to the build board?

- Printing failed: It is usually due to environmental factors such as insufficient support for suction on large cross-sections, insufficient normal/lift exposure time or decreased temperature. Check the layer alignment and reevaluate the support/orientation.

- Adhesion fault: Incorrect beds, insufficient exposure time for the bottom layer, dirty or damaged build plates (FEP membranes may be cloudy or scratched) or incorrectly mixed/agitated resins are common reasons.

-

How to remove resin support from tail (such as tail) (such as tail)?

- Delete support back do the laundry forward Final curing. Carefully cut a thick support substrate using a rinse cutter. Use gentle manual pressure or hobby tweezers to peel off thinner support. Wear nitrogen-haired gloves to make it easier to hold. It is only cured after all the support is removed and the model is removed and clean and dry.

-

PLA and PETG and Squirtle resin – What is the best?

- Resin: Best for ultra-smooth surfaces and surfaces that capture tiny details. superior "exhibit" Perfect. More safety precautions and post-processing are needed. Maybe crunchy.

- PLA: Easiest printing, excellent colors, based on bio. Ideal for functional printing, larger models or beginners. More polishing is required to smooth the painting. Low heat resistance.

- PETG: More durable and heat-resistant than PLA, it is not as brittle as resin. Ideal for models that may be frequently processed or exposed to warm environments. It’s slightly bigger than PLA smooth printing.

- How does Greatlight assist my Squirtle 3D printing project?

- Greatlight offers a comprehensive solution:

- High complexity/scale: Print large or highly complex desktop printer functions with industrial SLS, SLM (metal) or adhesive jet (gypsum/ceramics).

- Professional materials: Use engineered grade resins, durable metals (stainless steel, titanium) or professional ceramics/adhesives for a unique aesthetic.

- Advanced completion: Professional support for removal, expert polishing/polishing, high quality painting (air gun/hand painting), plating and sealing services.

- Design Optimization and Consulting: Helps improve productiveness and post-processing of model files.

- We offer a truly one-stop shop, from digital models to exhibition-ready finished products. Custom quotes tailored with your Squirtle Vision!

- Greatlight offers a comprehensive solution: