Tamriel’s virtual landscape has attracted millions of dollars since Elder Scrolls V: Skyrim. For dedicated fans, the charm extends beyond the screen – in the tangible realm of 3D printing. This transformative technique allows players to live forever with their favorite dragon artifacts, creatures and symbols as physical collections. However, Skyrim Prints that achieve museum quality require more than a fan printer. It requires professional precision. Let’s browse from digital models to physical heirlooms.

The art of capturing the essence of the sky

Skyrim’s iconic designs – Dragon Priest masks, Daedric weapons, and even miniature dragons are all digital gaming assets. Unlike general models, these require thoughtful 3D printing:

- Polygon optimization: Game Assets selective details are rendered selectively in real time. 3D printing requires uniform mesh structure to prevent crashes or artifacts.

- Structural integrity: Functions such as Dwemer machinery or elongated weapon blades require internal support and balanced weight distribution.

- Texture Challenge: Surface details (e.g., wood grain on the bow or scales on the Alduin) are usually converted into printable geometry through advanced engraving or displacement mapping.

Production process: from pixels to plastic (or metal!)

1. Procurement and preparation models

Blender or Zbrush tools such as refined extracted game files. Key steps include hollow models to save material and add escape holes to resin printing.

2. Material selection

- Resin (SLA/DLP): Very suitable for complex Daedric artifacts or jewelry-like amulets. Perfectly capture rune engraving.

- Nylon (SLS): Great for durable, flexible items such as wearable armor pieces or easily bent dragon claws.

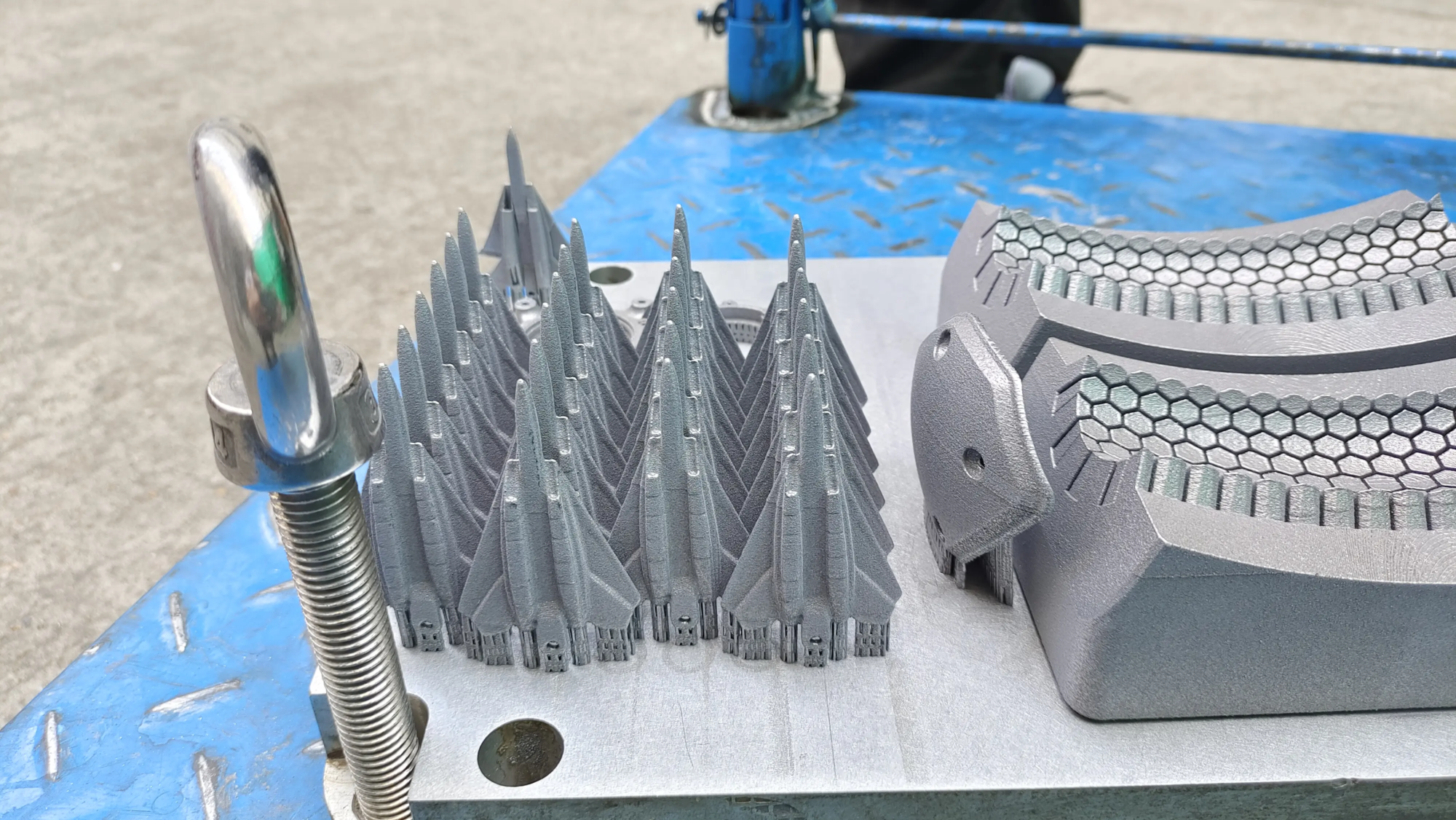

- Metal (SLM): For legend permanent. Steel, titanium or aluminum constructs ancient blades (e.g. dawn blades) or weathered dwemer gears.

3. Professional printing and post-processing

This stage separates desktop printing from professional-grade masterpieces:

- Support deletion: Precision cut to avoid surface scarring.

- Grinding and smoothing: Eliminate layer lines on curved surfaces, such as keels.

- finishing: Options include hand-painted, metallic plating or antique patinas of ancient artifacts.

- assembly: Multipart models (e.g., Guardian’s Stone) require seamless bonding and alignment.

Why collaborate with professional rapid prototyping services?

Creating Skyrim works worthy of display involves technical complexity beyond typical DIY printing. Working with experts to ensure:

- accuracy: Industrial SLM/SLS printers reduce details to 0.05mm tolerance, crucial elves armor wire.

- Material versatility: Use aviation grade metals or specialty resins that are not available to consumers.

- Structural Analysis: Prevent failures in delicate structures such as Mora’s antennae through pressure simulation.

- Proportional flexibility: Print life-size Empire helmet or desktop-sized Sovngarde door.

The company likes it Great Elevate this process with an end-to-end solution, combined with Industrial SLM 3D Printermetallurgical expertise and post-processing by craftsman leaders transform the Skyrim concept into a heirloom ready for gallery.

Creator and copyright role

In Skyrim’s modification community, when fan projects flourish, selling prints requires Bethesda’s permission. Individually, non-commercial prints are fairly used, but creators should:

- Credit original asset designer.

- Avoid monetization unless authorized.

- Use original redesign for commercial enterprises (e.g., stylized dovahkiin statue).

Conclusion: Forge your legacy

Skyrim 3D printing combines digital art with tangible craftsmanship, allowing fans to master the game’s knowledge. While Hobby printers provide a starting point, professional services unlock unprecedented fidelity, especially for complex metal or large dioramas. Materials science, structural engineering and proficiency make expertise essential.

With the Greatbights printing like the Greatmights Indromination Intrunial Infrade, it became a reality to convert Ysgramor’s axe or Serana’s dagger into audible steel. These physical creations not only celebrate the legacy of the sky, but also push the boundaries of game-inspired art.

FAQ: Skyrim 3D Printing

Q1: Can I print the Skyrim game file directly?

A: Extracted game assets usually require mesh repair, reducing polygons and supporting structures. Tools such as Netimmerse (NIF) converters and grid mixtures are crucial.

Q2: Which materials imitate the weathered metal appearance of Skyrim?

A: Bronze with acid hair (SLM printing) or stainless steel with electroplating agent finish. For lighter items, resin prints can mimic silver with metal coatings.

Question 3: How to avoid warping with large drawings (e.g., keel statues)?

A: Industrial printers with heating chambers (such as those used) can prevent thermal stress. Direction optimization and process monitoring are key.

Q4: Is the cost of metal printing too high?

A: Titanium or gold prints are ordered to price at high prices, but economical alternatives exist:

- Hollow steel model with brass plating.

- Polymer prints with cold cast metal powder coating.

- Aluminum alloy (50% lighter than stainless steel).

Q5: What is the typical turnover time for professional Skyrim Printing?

A: For resin: 1–3 days + finished. High resolution metal printing takes 2-5 days (printing) plus 3-7 days of paint/polishing. Complex multi-part collections expand the timeline.

Question 6: Can professionals deal with multi-material prints (e.g., glowing soul gemstones)?

A: Yes. Combinations such as translucent resin (GEM) + immersed in silver metal (setting) are possible. LED or phosphorescent paint adds lighting after insertion.

Dedicated to pioneers, forge reality from fantasy, like Great Mix craftsman skills with cutting-edge SLM 3D printing for unparalleled creation. From file optimization to custom metallurgy, we offer end-to-end prototyping, and we enable gamers to move beyond the digital divide. Explore custom Skyrint tribute works with Greatlight’s experts.