Beyond the glass: The rise of smart sips and 3D-printed beverages

The world of food and drink is on the cusp of a revolution, moving beyond mere sustenance and towards personalized, interactive and visually stunning experiences. At the forefront of this transformation is an exciting innovation: Smart Sips, powered by 3D printing technology. Imagine a drink that isn’t just poured, but crafted layer by layer – forming intricate ice decorations, personalized nutrient infusions, or even transformed into edible sculptures in your glass. This isn’t science fiction; This is the rapidly evolving reality of the convergence of additive manufacturing and culinary arts.

How do 3D printed drinks actually work?

Unlike printing plastic or metal objects, 3D printing drinks involves specialized technology designed for consumable materials:

- this "ink": Replaces molten plastic with edible "ink" be used. These are often purees, gels, foams, liquid chocolate, plant-based pastes, or even cocktails themselves, carefully formulated to have the right viscosity and flow characteristics.

- process: Food grade extrusion printers are the most common. Imagine a precision syringe system mounted on a robotic arm.

- Edible materials are packed into boxes.

- Digital 3D models (e.g., intricate lattice ice cubes, delicate flower decorations, multi-layered lenses) indicate the printer head.

- The printer deposits edible materials layer by layer onto a build plate (usually a glass or directly into a serving container) or even directly into a liquid substrate.

- Complex structures may involve support materials (also edible) that dissolve upon contact with the beverage.

- Practical application examples:

- Signature decoration: Print unique ice shapes that melt more slowly due to reduced surface area, or create edible flowers/patterns on top of cocktails.

- Snacks with a variety of textures: Create layered drinks where each layer has a unique flavor or texture (e.g., a crunchy chocolate shell surrounding a liquid center suspended in a cocktail).

- Personalized nutrition: Precisely microdosed vitamins, supplements or probiotics are embedded directly into the beverage’s edible structure.

- Effervescent design: Print structures that dynamically interact with carbonated liquids, creating mesmerizing patterns of bubbles.

Why Choose Smart Sipping? Compelling advantages:

- Extreme customization: Customize the flavor profile, texture, nutritional content and visual design of each drink to your personal preference or dietary needs.

- Reduce waste: Print precise quantities, minimize spills or unused ingredients, and create unique tables for enhanced portion control.

- Unparalleled presentation: Elevate the dining/drinking experience with visually stunning, tailor-made designs that are impossible to achieve manually.

- Innovation and novelty: Create new beverage categories and sensory experiences, taking everything from interactive drinks to molecular gastronomy to the next level.

- Speed and consistency: Once programmed, complex designs can be replicated perfectly and quickly, maintaining quality in high-volume environments such as bars or events.

Challenges and considerations:

Smart Sips technology is still in its maturity stage.

- Materials Science: The development of a wider range of stable, safe and flavor-neutral edible printed materials remains a focus.

- Speed and scale: While complex decorations are coming at a rapid pace, high-volume, fully printed complex drinks for mass production are still in development.

- Regulations and Safety: Ensuring strict hygiene standards throughout the printing process and classifying new edible materials requires a clear regulatory framework globally.

- cost: The initial and operating costs of specialized printers and edible materials can be high.

The role of advanced manufacturing: driving the beverage revolution

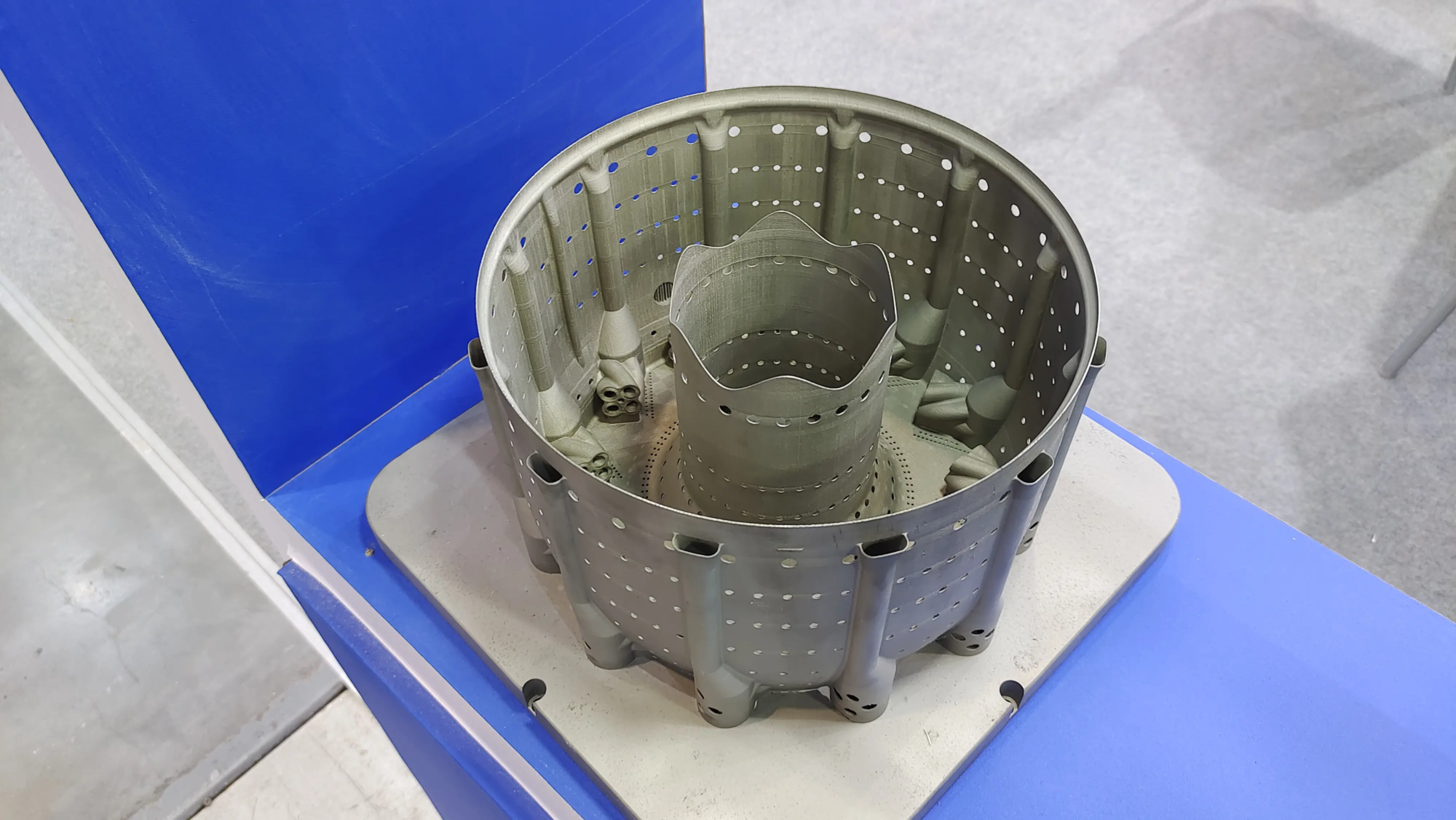

Creating the reliable, precise machinery needed to make smart Sips a reality requires expertise in advanced manufacturing—exactly the area the company loves huge light Outstanding. Although GreatLight focuses on high precision Metal 3D printing (SLM – Selective Laser Melting)whose core capabilities lie in Rapid prototyping and custom manufacturing Playing a vital indirect role in this emerging field:

- Beverage Printer Component Prototyping: The complex internal mechanisms of food-safe 3D printers (nozzles, fluid channels, mixing chambers requiring complex geometries, or heat-resistant components) can be rapidly prototyped and optimized using GreatLight’s metal SLM technology. This allows printer manufacturers to quickly iterate designs and test functionality using durable, high-detail metal parts.

- Custom Tools and Fixtures: Manufacturing custom jigs, fixtures or specialized tooling required to assemble or maintain beverage printers greatly benefits from GreatLight’s ability to produce custom complex metal parts with high dimensional accuracy on demand.

- Advanced materials for harsh environments: Parts exposed to cleaning chemicals, constant wear, or requiring food-grade certification can take advantage of GreatLight’s capabilities and be manufactured from specialized durable metals.

- One-stop solution: From initial prototype to finished product, post-processing parts including smoothing, polishing or applying a food-safe surface treatment, GreatLight offers comprehensive services that accelerate the development cycle for companies building smart water dispensers.

The future is now

The potential of 3D printed drinks goes far beyond novelty. We foresee:

- Hyper-Personalized Nutrition: Beverages uniquely formulated and structured for individual health goals, allergies and taste preferences.

- Automated food bar: Robot bartenders use 3D printing and traditional techniques to instantly create custom cocktails and drinks like never before.

- Redefining sustainability: Optimized ingredient usage and custom edible packaging printed alongside the drink itself.

- Interactive catering: Beverages designed to change shape, texture, or flavor when you drink them or when combined with other elements.

As materials science evolves and manufacturing technologies like GreatLight continue to advance, barriers will decrease, making smart sips increasingly accessible and transformative for the beverage industry, from high-end mixology to personalized health drinks.

in conclusion

Smart Sips represent a fascinating fusion of culinary arts, digital design and advanced manufacturing. 3D printed drinks offer a glimpse into a future where drinks become personalized experiences, reducing waste and pushing the boundaries of creativity. Although material, regulatory and scale challenges remain, the trajectory is clear. The precision and speed brought by rapid prototyping experts like GreatLight are critical to developing the complex machinery needed to make the technology robust, efficient and ready for wider adoption. This revolution is not just about what we drink, but how it is conceived, made and experienced. Your next sip might just be a brew, not a pour.

Frequently Asked Questions About Smart Sips: 3D Printed Drinks

-

Are 3D printed drinks safe?

- Yes, 3D printed drinks are safe when produced using food-grade certified printers, edible printing materials approved for consumption, and following strict hygiene protocols. It is critical for manufacturers to ensure that the entire system meets food safety standards.

-

What does a 3D printed drink taste like?

- Taste depends entirely on consumption "ink" Used. High-quality materials ensure authentic flavor. The real innovation usually lies in texture combinations or visual presentation, rather than radically altering the base flavor (unless layered or infused in complex ways).

-

Where can I try 3D printed drinks?

- Currently, they are most prominent in high-end cocktail bars, luxury hotels, experiential restaurants and technology exhibitions. As the technology matures and costs come down, its availability is expected to expand into gourmet cafes and potentially health-focused venues for personalized energy drinks.

-

Can I print drinks at home?

- Dedicated consumer-grade food printers are still in their infancy, focusing primarily on simpler tasks like pancake batter or cookie dough decorating. Complex multi-material beverage printing currently requires specialized commercial equipment. However, as technology advances, simplified versions for home use may become available.

-

Is this related to 3D printed plastic bottles/cups?

- It’s adjacent but different. While 3D printing is used to create custom container Using food-safe plastics or potentially metals (through prototyping/moldmaking partners like GreatLight), Smart Sips specifically refer to The liquid or edible structure of the drink itself Additive manufacturing in progress.

- How long does it take to 3D print a drink?

- The time difference is huge. A simple ice cube or garnish can take anywhere from a few seconds to a few minutes. Complex multi-layered cocktail ingredients or complex suspensions in drinks may take several minutes. Speed is a key development focus for wider adoption.