Mastering Grip Strength: The Ultimate Guide to Solving 3D Printing Bonding Problems

Do you get that frustrating feeling when you check your 3D printer only to find a mess of filament instead of the original part? Poor bed adhesion is the bane of successful printing and can lead to warping, shifting or catastrophic detachment. This is one of the most common obstacles faced by makers and professionals alike. At GreatLight, as experts in industrial-grade metal 3D printing (SLM) and rapid prototyping, we see and solve bonding challenges every day. This guide delves into the root causes and provides practical, effective solutions to ensure your prints stick where they should.

Why bed adhesion is so important

Proper adhesion not only prevents print failures; It is the basis for dimensional accuracy and structural integrity. The critical first layer determines how well subsequent layers are built on top of it. Poor adhesion can lead to warping (corner lifting), layer shifting, or complete separation, resulting in wasted time, material, and frustration. For demanding applications such as functional metal prototypes or end-use parts where precision is non-negotiable, mastering adhesion is critical.

Analyzing the reasons: why printed matter is not sticky

Several factors conspire to hinder adhesion. Isolating the culprit is the first step:

- Bed surface problem: A dirty, dusty, greasy (from fingerprints) or damaged print platform is enemy number one. Residues form a barrier between the material and the surface.

- Improper bed leveling: An uneven or uneven bed will cause inconsistent nozzle heights. Too high = weak squeezing force; too low = scratched or clogged filament.

- Improper bed temperature: Too cold and the material cools too quickly and will shrink and detach. Too much heat (especially with plastics like PLA) can cause "elephant feet" Or make the material too soft to hold its shape.

- Suboptimal first-tier setup: Print speeds that are too high, initial layer heights are incorrect, or insufficient material flow (extrusion factor is too low) can prevent proper bonding.

- Insufficient build surface adhesion aid: Exposed glass or metal often lacks inherent "hold tightly" for many materials. Bed adhesives such as glue, tape, or special coatings are usually required.

- Material Incompatibilities and Environmental Factors: Different plastics (PLA, ABS, PETG, nylon) and metals have very different bonding requirements. Ambient air currents, low ambient temperatures (<15°C), or high humidity can exacerbate the problem.

- Model design flaws: Large flat surfaces, sharp corners, and insufficient contact area with the bed will increase warping forces.

Conquer adhesion: proven solutions for every situation

Now, let’s tackle these issues head-on with actionable fixes:

-

Master bed preparation and leveling:

- Clean relentlessly: forward every Print and clean the bed rigorously. Use >90% isopropyl alcohol (IPA) and a lint-free cloth. Avoid using acetone unless your bed surface is particularly resistant to acetone.

- Level like a pro: Use manual paper calibration (aim for slight resistance under the nozzle) or invest in a grid leveling system. Recheck regularly, especially after temperature changes or bumps.

- To replace damaged surfaces: If the PEI boards are scratched or the glass bed is chipped, replace them. GreatLight uses an optimized, calibrated SLM metal printing build platform to ensure bonding integrity from the start.

-

Optimize temperature settings:

- Heated bed: Use the manufacturer’s recommended bed temperature as a starting point. For easily deformed materials (such as ABS) or large parts, the temperature rises by 5-10°C. Use a shell to stabilize the ambient temperature, this is especially important with ABS or nylon. For metals in SLM, precise preheating of the substrate is automatically controlled.

- Check the first layer nozzle temperature: Sometimes slightly increasing the nozzle temperature of the first layer (5-10°C) can improve flow and adhesion.

-

Adjust the first layer precision:

- slow down: Significantly reduce first layer speed (e.g. 10-20 mm/sec). This gives the filament more time to bond.

- Adjust Z-axis offset: Make sure the nozzle gap is set correctly for a gentle result "Flatten." The first layer of lines should be slightly flattened and fully blended, not rounded or barely touching.

- Increase first-tier traffic: Increase the first layer extrusion width (e.g., 150%) and/or the extrusion multiplier (e.g., 105%) to lay down more material, thus increasing the contact area.

-

Use effective bed adhesives and surfaces:

- Choose your weapons wisely:

- PEI sheet: Great for PLA, PETG, ABS (with shell). Clean well with IPA. Light sanding can restore grip.

- Glue stick (PVA): Simple, effective and suitable for PLA/ABS on glass. Forms a semi-soluble barrier that aids adhesion and part removal.

- Painter’s Tape (Blue Tape): Perfect for PLA; provides good grip and easy release. Make sure it applies smoothly and without bubbles/rising.

- Magigoo, Dimafix, 3DLAC: Advanced adhesive formulated for specific materials; often provides better performance and cleaner results than glue sticks.

- BuildTak and similar coatings: Textured surface provides strong grip on a variety of materials.

- (Advanced) Raft and Edge: They are generated inside a microtome, which significantly increases the surface contact area. The rim is a thin skirt welded to the edge of the part; the raft is a thick sacrificial lattice printed underneath.

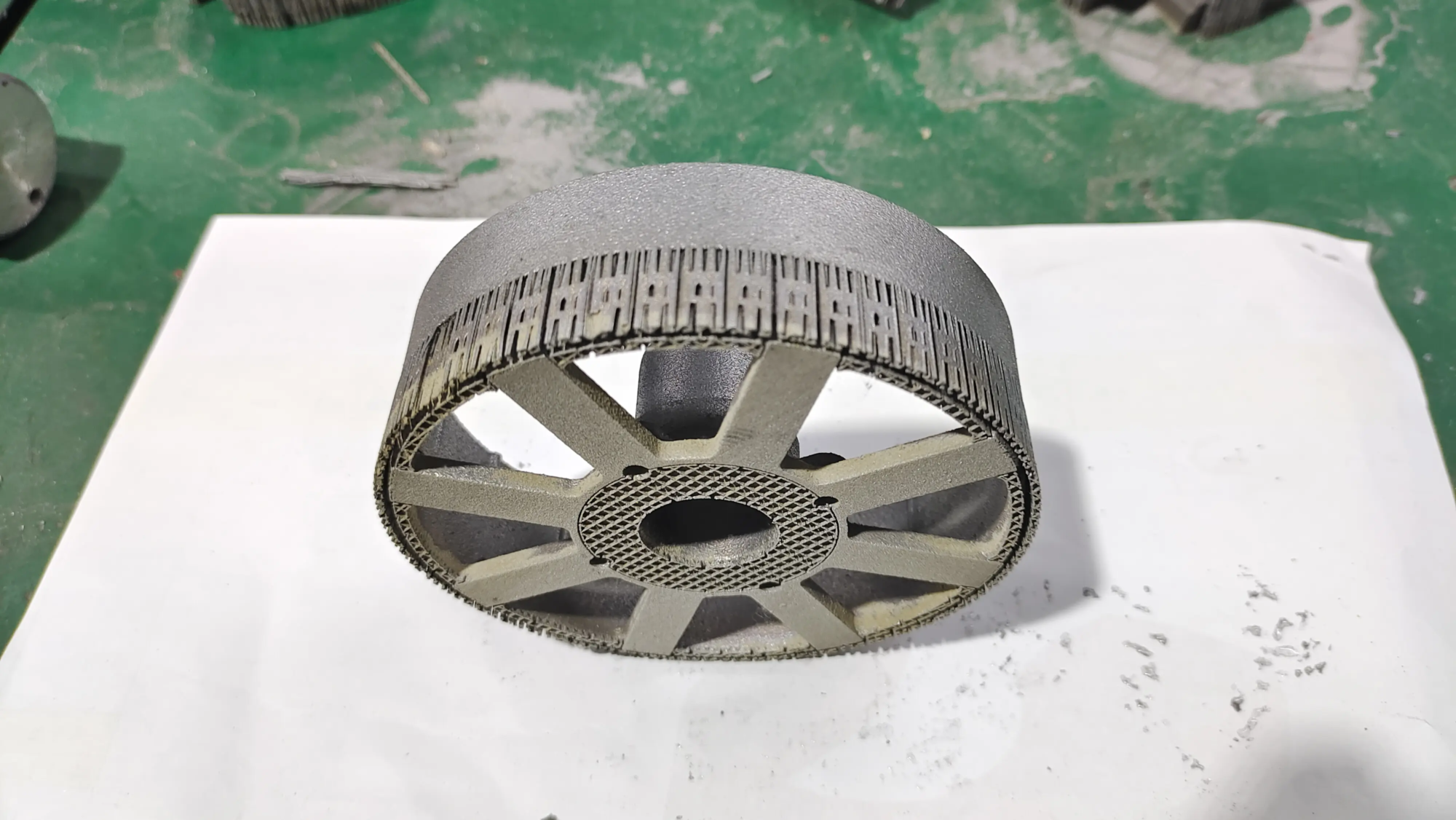

- Metal printing: In SLM, adhesion is ensured through precise parameter control (laser power, scanning speed, filling distance) and specialized build plate surface treatment. Post-processing (wire cutting) reliably separates parts. GreatLight leverages an extensive materials database and process expertise to automate optimization.

- Choose your weapons wisely:

-

To counteract warping forces:

- Intelligent design: Add fillets, lugs (little discs at the corners), or chamfers instead of sharp 90-degree angles. Make sure large, flat parts have adequate contact area.

- To enable the windshield: Slicers create thin walls around the print area to trap hot air and prevent drafts.

- Materials and Environmental Controls:

- Use high quality filament/powder: Filaments that absorb moisture (nylon is notorious for that!) will reduce performance – dry them thoroughly. GreatLight carefully controls the environment and powder handling of metals.

- Eliminate drafts: Close doors/windows and protect the printer with a special or DIY enclosure.

- Control humidity: Use a dehumidifier, especially for moisture-absorbent materials.

When DIY gets tough: The professional advantage

Even with careful calibration, hobbyist printers and complex geometry/material requirements can push DIY setups to their limits. Persistent adhesion problems, especially with high-value materials such as metal powders or advanced engineering polymers, indicate that it is time for expert intervention.

This is the advantage of GreatLight. As a professional rapid prototyping manufacturer, we bring industrial-grade solutions to bonding challenges:

- Advanced SLM technology: Our precision metal 3D printers (using selective laser melting) feature closed-loop thermal management, inert atmosphere control, and laser parameter optimization to ensure perfect fusion of the first layer to the build plate every time.

- Process expertise: We maintain an extensive material configuration, including specialty alloys, and proven build strategies to prevent warpage and ensure dimensional stability starting at one micron.

- Comprehensive post-processing: Adhesion challenges are not limited to printing. Our one-stop services include professional part disassembly (such as wire EDM for metal parts), stress relief heat treatment and surface finishing to ensure parts meet the most stringent specifications.

- Quick customized solution: Need a complex, high-precision part with no adhesion issues? GreatLight provides fast, cost-effective custom prototyping and production, handling everything from material selection to final finishing.

Conclusion: Persevere to succeed

Achieving perfect 3D printing bonding depends on understanding the root causes and implementing tailor-made solutions. Start with basic hygiene and calibration, then optimize temperature, speed and surface. Use appropriate adhesives or design aids when needed. For the most demanding projects, leveraging expertise and industrial-grade equipment, such as GreatLight’s SLM capabilities, provides a reliable path to obtaining perfectly adhered, high-precision parts. By mastering adhesion, you can turn frustration into consistent printing success, unlocking the true potential of additive manufacturing.

FAQ: 3D printing bonding issues

Q1: I have been using IPA to clean the glass bed, but PLA still won’t stick. What to give?

A: IPA removes grease but leaves a small residue. Try cleaning the glass thoroughly with hot water and Dawn dish soap, then dry it completely. For PLA, apply a thin layer of PVA glue stick or diluted white glue. clean Glass provides excellent adhesion.

Q2: ABS is deforming like crazy! help!

Answer: ABS needs warmth! Make sure your bed is hot enough (100-110°C), the heated bed is clean, an enclosure is an absolute must to eliminate drafts and built-up heat, and seriously consider a large brim or full raft. Magigoo ABS or ABS Slurry are highly effective adhesives. High ambient room temperature also helps.

Q3: A raft is always better than a hat?

Answer: Not necessarily. The edges effectively increase the contact area around the perimeter of the part and save material. Raft creates an entirely new base layer underneath the model, consuming more material and printing time. Use brim for edge warping; reserve raft for models with small initial contact areas or weak/fragile layers.

Q4: PETG stick also Great for my PEI form – print it out for me!

Answer: A common PETG trap! Allow the bed to cool completely – PET’s grip will weaken significantly as it cools. If it gets stuck, gently bend the PEI piece (if removable). Apply a very light Glue stick coating acts as Release agent When using PETG on PEI. Never pry; use a plastic scraper specifically designed for PEI.

Q5: How does a professional 3D printing service like Honglaite ensure the adhesion of metal printing?

A: Industrial SLM printers use tightly controlled environments (oxygen-free chambers), precisely preheated build plates, delicate support structures integrated into the print file to counteract thermal stress, and highly optimized laser scanning parameters. GreatLight combines cutting-edge equipment, proprietary materials knowledge and automated quality monitoring to guarantee consistently perfect adhesion to complex metal prototypes and production parts. Need sturdy, non-deformable metal parts? We eliminate the guesswork.