The Forge Reborn: How 3D printing revolutionized Spartan armor

Dressed in distinctive bronze and leather, the image of the Spartan warrior remains an enduring symbol of discipline, strength and resilience. Over the centuries, recreating this iconic armor has required painstaking craftsmanship, expensive materials and a lot of time. Now, a technological revolution—advanced 3D printing—is breathing new life into these ancient designs, making custom, durable Spartan armor more accessible and sophisticated than ever. Modern forges equipped with powerful lasers and cutting-edge software are replacing hammers and anvils, and companies like GreatLight are at the forefront of this transformation.

Beyond role play: The power of metal 3D printing

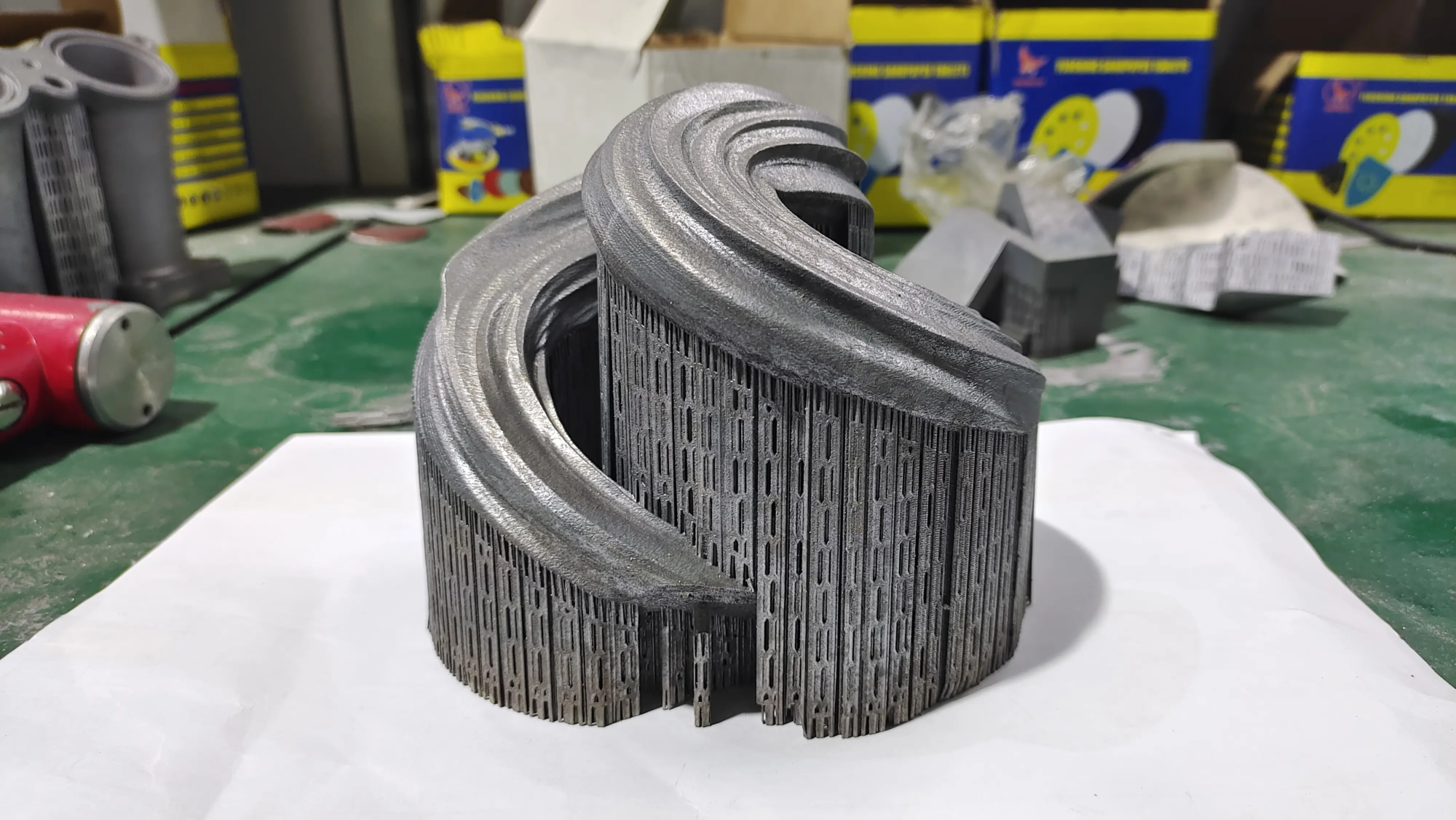

While 3D printed plastic armor props are common in cosplay, true Spartan-style armor requires the strength, weight, and authenticity of metal. That’s where technology like this comes in Selective Laser Melting (SLM) Really shine:

- Direct metal fabrication: SLM printers use high-power lasers to precisely fuse layers of fine metal powder to build complex geometries layer by layer directly from digital models. Unlike plastic prints, this creates fully dense, solid metal parts.

- Unparalleled complexity: Intricate details – the iconic Lambda (Λ) symbol, embossed musculature, intricate helmet designs, segmented fins (armor flaps) – that would have been extremely difficult, expensive or impossible to achieve with traditional metalworking methods such as forging or casting are now easily achievable. 3D printing unleashes design freedom.

- Numeric precision: Replicating historical elements or achieving modern interpretations requires absolute accuracy. SLM ensures that every proportion, curve, and joint is built to precise numerical specifications, guaranteeing a symmetry and consistency that cannot be achieved by handcrafting alone.

Building Spartan with Cutting-Edge Technology: The GreatLight Advantage

Creating functional and beautiful Spartan armor via 3D printing requires specialized expertise and technology. As a leading brand in rapid prototyping, huge light Ability to solve these complex challenges:

- Advanced SLM Printer: GreatLight uses state-of-the-art industrial SLM equipment. This ensures that the layer-by-layer fusion of high-quality metal powders produces parts with superior mechanical properties – crucial to the parts that inspire Spartan strength.

- Material mastery: Need the weight and protection of steel? Titanium is more elastic and lighter? Maybe a bronze finish? GreatLight offers a wide range of high quality metal alloys (such as titanium Ti6Al4V, stainless steel, aluminum alloys and tool steels) and can advise on the best materials to balance aesthetics, weight, durability and application (display, reproduction, functional elements).

- Rapid prototyping and iteration: Designing the perfect Spartan breastplate or helmet often required experimentation. GreatLight excels at rapid iteration. Quickly create functional prototypes to test fit, aesthetics and clarity. Need adjustments? Design changes can be easily implemented digitally and new prototypes can be quickly printed, significantly speeding up the development process.

- One-stop post-processing: The original 3D print peeled off the printing plate and required refinement to achieve the desired spartan finish. GreatLight provides comprehensive post-processing:

- Support removal: Expertly remove delicate support structures required during printing.

- Surface treatment: Sand blasting, grinding, polishing, hand finishing – from raw metal surfaces to mirror polish or textured finishes that simulate aged bronze.

- Heat treatment: Enhance strength and durability as needed.

- Non-destructive testing (NDT): Ensure structural integrity through techniques such as dye penetration testing.

- Customized: Your Vision, Metal Casting: True to Spartan’s spirit of standing out, GreatLight allows for complete customization. Scale the armor to fit any body type, incorporate unique symbols, modify ergonomics for greater comfort, or design mounting points – the possibilities are limited only by imagination (and physics!). Our teams work closely to transform your concepts into manufacturable digital models.

More than just a prop: a multifunctional app

3D printed Spartan armor goes beyond simple display models:

- High fidelity reenactment: Providing durable, historically inspired (or accurately replicated) gear for serious re-enactors looking for authenticity without the substantial cost of traditional craftsmanship.

- Film and theater production: Quickly and cost-effectively create custom, detailed, lightweight (if desired) armor for your actors, allowing for hero props, background parts and more.

- Advanced role play: The use of real metal parts elevates garments beyond plastic, providing unparalleled realism, weight and prestige. You don’t need to master leatherworking skills to craft segmented armor.

- Functional Art and Collectibles: Create stunning museum-quality display pieces or limited-edition collectibles with intricate forms and premium finishes.

- Protective equipment concept: Inspire novel concepts for modern armor systems, leveraging design freedom to explore geometry-driven protection. (Note: 3D printed armor for actual ballistic protection is very complex, requires rigorous testing/certification, and is different from clothing/larp/re-enactments.)

Why choose 3D printed Spartan armor instead of traditional methods?

- Complexity made simple: Create structures and details not possible with sheet metal forming or casting.

- speed: The speed from digital design to finished metal part is significantly accelerated, which is especially important for custom projects.

- Cost effectiveness (for complexity): Eliminates expensive tooling (molds, dies) typically required for traditional manufacturing of complex shapes. Ideal for small batches or one-off production.

- Lightweight: Optimizing topology to reduce material usage and weight without sacrificing structure is critical for wearable components.

- Personalization: Each piece can be uniquely customized without incurring exorbitant additional costs.

in conclusion

The spirit of the Spartans is embodied in their iconic armor and continues to inspire people thousands of years later. Advanced 3D printing, specifically SLM technology, offers a revolutionary way to recreate or reimagine this tradition. It unlocks an unprecedented level of customization, intricate detailing and versatility that goes far beyond a simple plastic replica.

However, bringing the rugged, complex metallic Spartan armor design to life requires the right combination of cutting-edge technology and deep manufacturing expertise. As a premier rapid prototyping manufacturer with advanced SLM printers, comprehensive material selection and seamless one-stop post-processing services, GreatLight provides the essential bridge between your digital designs and tangible, spartan form. We specialize in solving the complex challenges of custom metal rapid prototyping, transforming your vision of modern Spartan armor—whether it’s historical awe, cinematic spectacle, or personal expression—into a tangible, high-quality metal reality. Partner with us and experience modern forging with authority.

Frequently Asked Questions (FAQ) about 3D printed Spartan armor

Q1: Is 3D printed metal Spartan armor really strong?

A1: Yes, when produced using SLM technology with appropriate aerospace-grade metals such as titanium or high-strength steel, the resulting parts are fully dense and have excellent mechanical properties. They are extremely durable and suitable for handling, display, reenactment (impact resistance is similar to forged parts of the same thickness) and demanding role play. However, they are not inherently ballistic armor.

Q2: What materials are most suitable for making wearable 3D printed Spartan armor?

A2: It depends on your priorities:

- Lightweight and strong: Titanium alloy (Ti6Al4V) is ideal, but more expensive.

- Good strength and cost: Various stainless steels (such as 316L) provide a good balance.

- Cost-effective and lightweight: Aluminum alloys are popular but are generally softer.

- aesthetics: Tool steel can be polished to imitate bronze or achieve a dark finish. GreatLight can provide recommendations based on your specific needs.

Q3: How durable is the surface finish?

A3: The original SLM print has a slightly grainy texture. Post-processing significantly improves durability. Polishing produces a smooth, long-lasting surface. Sandblasting provides a strong, even matte finish. A protective clear coat can be used to minimize oxidation and maintain appearance.

Q4: How much does the finished armor weigh compared to traditional metal?

A4: By strategically designing components using topology optimization, engineers can often make 3D printed parts lighter than solid cast parts while maintaining strength. The final weight depends heavily on the design complexity, the materials chosen (titanium is lighter than steel) and the wall thickness used.

Q5: Can Gretel handle the entire process from my design concept to the finished product?

A5: Of course! This is a core strength. GreatLight provides a true one-stop shop:

- Design consultation and optimization (if required).

- Precision SLM 3D printing.

- Comprehensive post-processing (support removal, heat treatment, finishing).

- Quality inspection.

- Assembly (if required), packaging and delivery.

Q6: What format of files do I need to provide?

A6: GreatLight requires 3D models in standard CAD format, e.g. .STEP (preferred), .IGESor .STL (Be careful to ensure adequate resolution). The complexity of the Spartan armor design should be accurately represented in the documentation.

Q7: How does the cost compare with traditional metal processing?

A7: For highly detailed, customized, or low-volume production runs (e.g., one-piece kits, small groups), 3D printing is often more cost-effective than traditional methods that require custom molds and extensive manual labor. Simple forms of mass production may favor traditional methods, but this is less common with complex Spartan designs.

Q8: Can you simulate a historical patina or aged bronze finish?

A8: Yes! Advanced post-processing techniques, including professional chemical patination and expert hand finishing by GreatLight technicians, can create a variety of authentic-looking distressed metal finishes, including bronze, brass and weathered steel looks.

Ready to bring your Spartan vision from history into tangible metal reality? Partner with GreatLight to provide professional 3D printing solutions. [Implied Call to Action – Link would go here to GreatLight’s contact page or quote request form]