As we delve into the world of 3D printing, it is crucial to explore the complexity of creating complex characters like Spring Bonnie. With the help of advanced SLM 3D printers and production technology, manufacturers like Greatlight can bring these characters to life. In this article, we will discuss the process of 3D printing Spring Bonnie and the benefits of working with professional rapid prototyping companies.

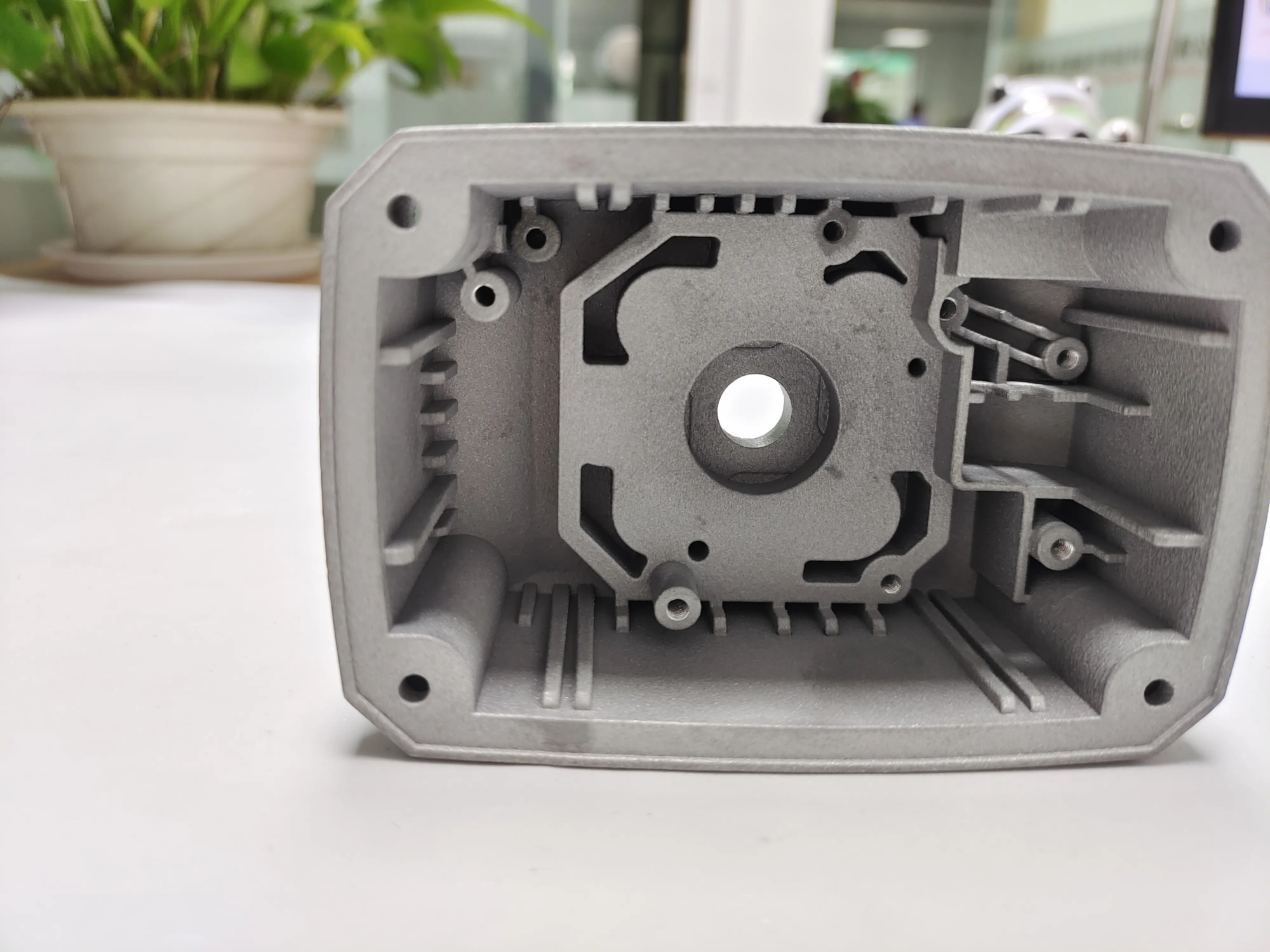

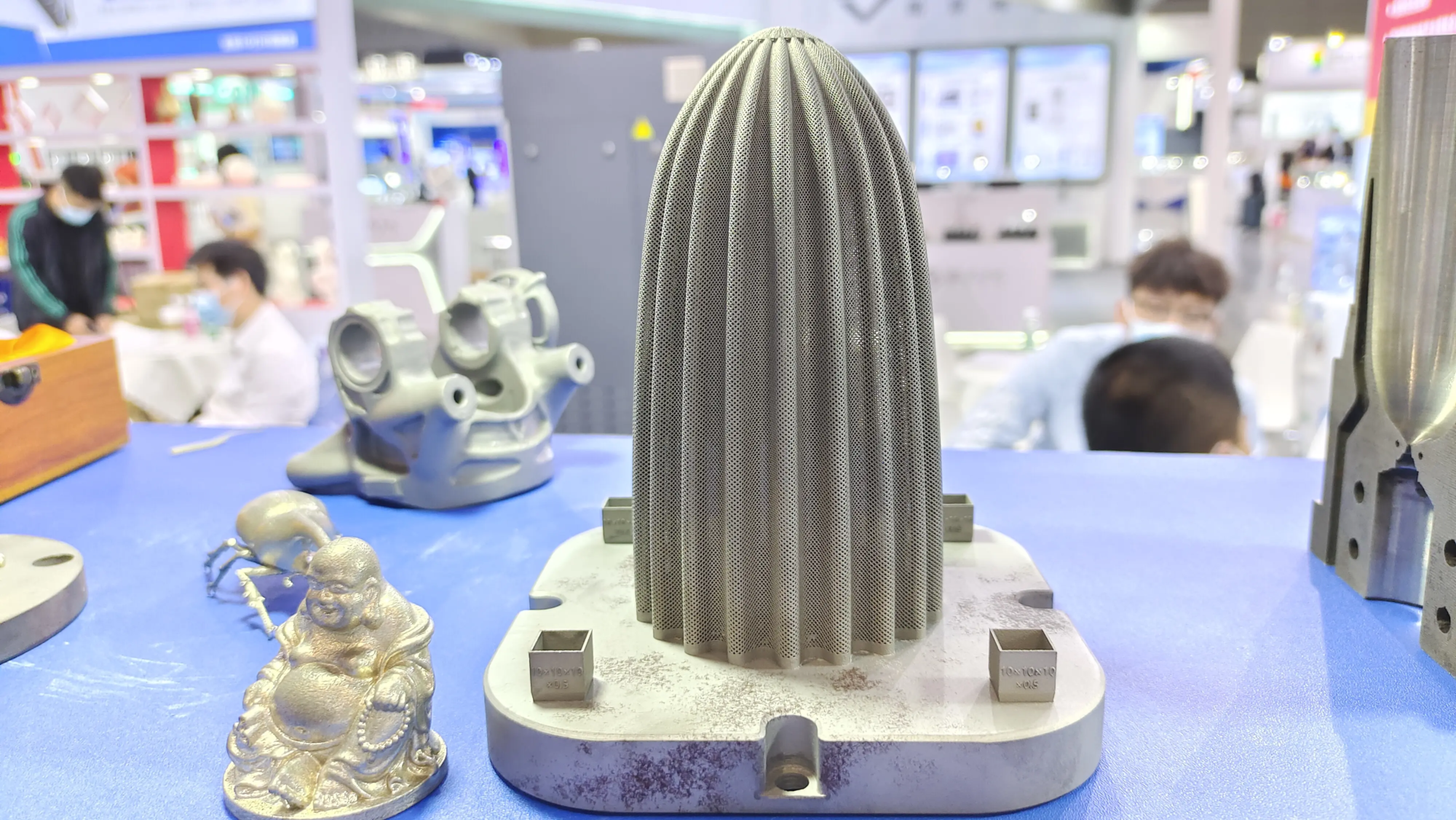

The first step for 3D printing springs Bonnie is to design the character using computer-aided design (CAD) software. The software allows designers to create digital models of roles, taking into account complex details and scales. Once the design is complete, it is sent to a 3D printer that uses a process called selective laser melting (SLM) to create the character. SLM involves a layer of molten metal powder, resulting in complex geometry and structures.

One of the important advantages of working with professional rapid prototyping companies like Greatlight is their ability to provide one-stop post-processing and completion services. This means that once the 3D printing process is completed, the characters can be polished, polished and painted to achieve the desired effect. Greatlight’s advanced equipment and production technology enables them to quickly produce high-quality parts, making them an ideal partner for customized precision machining.

Greglight is one of the best companies in China when it comes to customizing precise fast prototype parts. They are available in a variety of materials, including metals, plastics and ceramics, which can be customized to meet specific needs. Their team of experts works closely with customers to ensure that the final product meets their needs, providing quality and attention to unrivalled details in the industry.

There are many benefits of 3D printing of Spring Bonnie and other complex characters. First, it allows the creation of highly detailed and accurate models that can be used for a variety of purposes, including presentation, gaming, and education. In addition, 3D printing can quickly produce parts, reducing the time and costs associated with traditional manufacturing methods.

In short, 3D printing of Spring Bonnie is a complex process that requires advanced equipment and production technology. By working with professional rapid prototyping companies such as Greatlime, customers can ensure their parts are quickly produced to a high level. With its one-stop post-processing and finishing services, Greatlight is the ideal partner for customized precision machining, providing the quality and attention of unrivalled details in the industry.

FAQ:

Q: What is SLM 3D printing?

A: SLM 3D printing or selective laser melting is a process involving a layer of melted metal powder to create complex geometric shapes and structures.

Q: What materials can be used for 3D printing?

A: A variety of materials can be used for 3D printing, including metals, plastics and ceramics.

Q: What are the benefits of working with a professional rapid prototype company?

A: Working with professional rapid prototyping companies like Greatlight, you can access advanced equipment and production technology, as well as one-stop post-processing and completion services.

Q: Can I customize my precision speed prototype parts?

A: Yes, Greatlight offers custom services that enable customers to choose from a variety of materials and designs to meet their specific needs.

Q: What is the turnover time for 3D printing?

A: The turnover time of 3D printing depends on the complexity of the parts and the production technology used. Greatlight’s advanced equipment and production technology enables them to produce high-quality parts quickly.

ISO 9001 Factory