Implementing the Impossible: Your Final Guide to the Star Destroyer of the Empire (and make it truly legendary)

The sheer slice of the Imperial Star Destroyer in space is imposed on the Imperial Star Destroyer, one of the most iconic images in science fiction. For decades, fans can only dream of having a large enough detailed copy to respect respect. The era of input 3D printing. The field that used to be high-end model kits or overly expensive commissions can now be achieved with surprising details on your own desk or workshop. But printing out the Star Destroyer is more than just hitting "ctrl+p." This is an important project that requires careful planning, technical knowledge and often industrial-grade features. This guide will let you browse the entire process, from model selection to final victory poses, making sure your SSD is ready to dominate your display shelf.

Phase 1: Preparation – Lay the foundation for victory

-

Right blueprint: A crucial first step! There are countless STL files, and the quality, scale and level of detail vary greatly.

- scale: Make a decision early! Consider the goal of displaying space and realism. The 70cm behemoth is impressive, but requires heavy-duty hardware. The 25cm model may be better suited for most home printers.

- Source quality: Looking for design models For printing. Look for clean topology (multiple geometry), logical segmentation (printable parts), sufficient wall thickness and pre-supported versions if resin is considered. Be wary of pure aesthetic models, which often lack physical printability. Sites such as cults3d, myminifactory, and Thingiverse are popular hunting grounds. Consider supporting talented designers! Community advice is gold.

- segmentation: Large models are always printed in many parts. Learn how the model breaks down – hull parts, engines, bridges, turrets. This can affect printing strategy and assembly complexity.

-

Material selection: Select the composition of the hull:

- Standard Plastics (Home Printing):

- PLA (beginner friendly): Easy to print, huge color choice, affordable. Ideal for smaller or fewer models. Easily warp on large parts and weaker under pressure/heat.

- PETG (Stronger Alternative): Increases in strength with PLA, temperature resistance and impact force relative to PLA. More flexible and reduces brittleness. Compared to PLA, printing is a bit challenging, but manageable. Best advice for larger FDM prints that require durability.

- ASA (weather resistance): Ultraviolet rays and weather resistance, good thermal deflection. Perfect for displaying works in a variety of environments. It is easier to bend and emit smoke, requiring ventilation.

- Engineering and Aesthetic Plastics (Professional): For projects that require maximum fidelity, strength or unique finish.

- ABS: Stronger than PLA/PETG, stronger and perfect for post-processing (grinding, steam smoothing). High warpage risk A closed, heated printer and expertise are required.

- Nylon (PA): Extremely tough, durable and somewhat flexible. Ideal for large functional parts. Need for high nozzle temperature and frequent humidity control – Professional machines perform well here.

- Resin (SLA/DLP/LCD): Unrivaled surface details and crispness! Perfect for complex command towers, turbocharger batteries and surface grebriangs. Ideal for medium-sized star destroyer or key coin assembly. Post-treatment (washing, curing) is crucial. Usually used for smaller size models or parts, this is due to volume limitations built on most consumer printers.

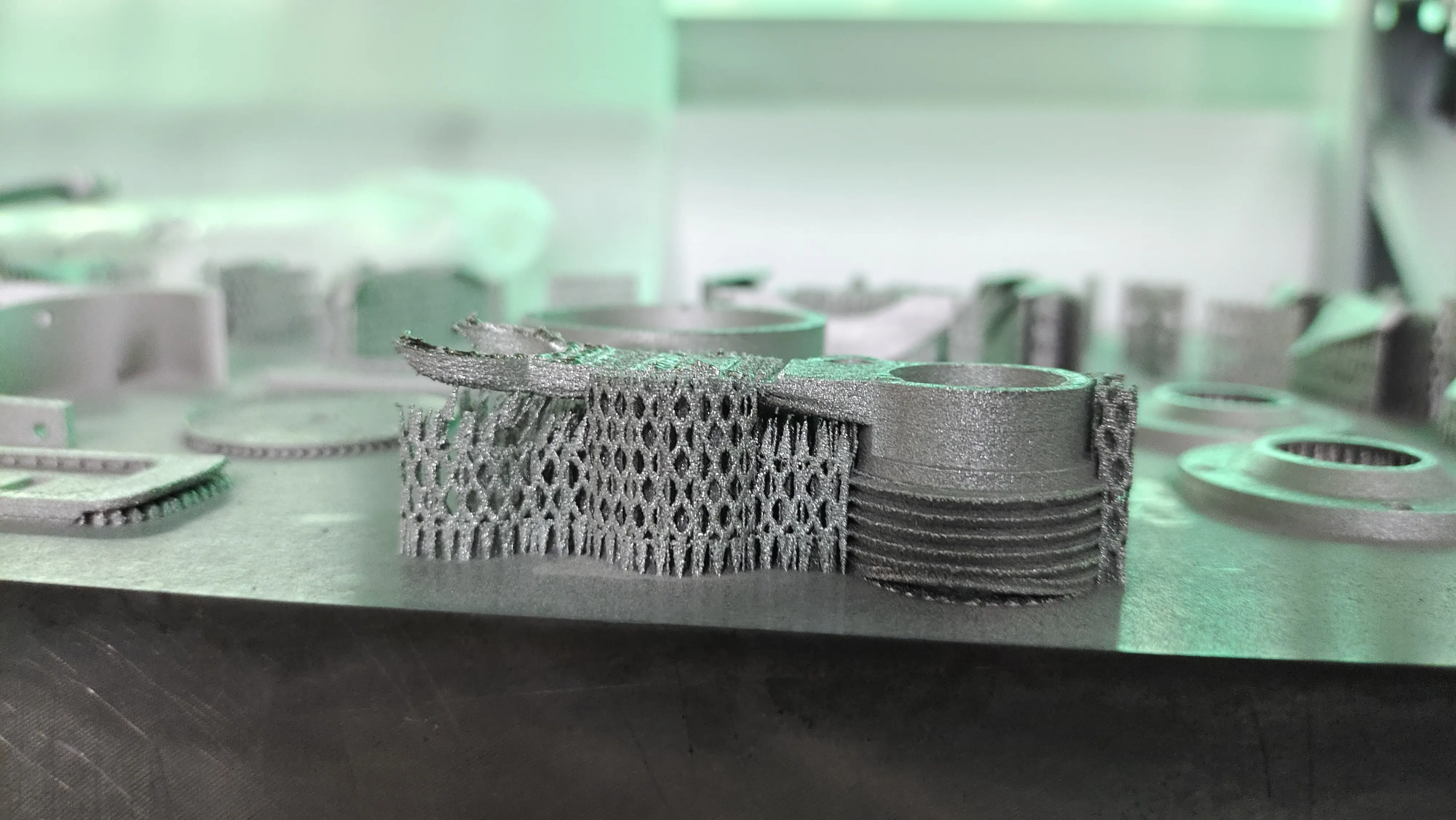

- Think bigger? Enter professional services: Target Museum-scale replicas (1M+) Or need High temperature materials (such as metal alloys)professional rapid prototyping is your own:

- SLS (Nylon 12): No support is required in hollow areas, resulting in incredible strength, lightweight and meridian-free parts. Ideal for large complex structures such as main hulls.

- SLM (Metal Printing): Really want one Stay still Star Destroyer Stainless steel, titanium or aluminum alloy? Selective laser melting creates completely dense metal parts with amazing details. This is Greatwith our advanced SLM capabilities and one-stop post-processing proficiency, transforming ambitious dreams into a tangible heirloom quality collection. We handle everything from precise slices to final finishing.

- Standard Plastics (Home Printing):

- Slicing Strategy: Destroyer Beam Plan Phase

- direction: Balances strength with visual quality. Printing large hull slices minimizes footprints vertically but adds weak lamellar lines horizontally. The tilted print can be a compromise. For almost all slicers, the impstar deuce i must be printed in each section! Better than an impossible print volume.

- support: Required for overhanging. Where possible (Cura) or custom support, use the tree’s support to minimize contact points and scar on delicate surface details. For finely detailed resin prints, supporting placement is an art form – it is highly recommended that you use pre-supported models unless you are an expert.

- Filling and walls:

- Large FDM parts:

- Focus on strength and framework: Use increased surrounding/wall (3-4+) instead of high fill percentage. Structural fill mode (energy, cubic) is used at lower density (10-20%).

- Consider internal reinforcement: Design channels for trusses, rods or threaded rods aligned along the long axis of the hull section. This is Critical For large FDM printing, to prevent sagging or breaking.

- Smaller parts/resin: Higher fillers may be aesthetics, but add materials/cost/time. 20-30% capacity/cube is usually enough to display a model display.

- Large FDM parts:

- Layer height: Aim at the thinner layers (0.1-0.15mm FDM, 0.03-0.05mm resin) to a smooth surface, especially at critical angles such as hull wedges. Thicker layers speed up the speed for thicker details.

- Adhesion and warpage prevention:

- FDM criticism: Glass-made plates or textured PEI are standard. Strong adhesives are not negotiable: Layered bed welds for ASA/ABS, Magigoo, 3DLAC or specialized mixtures. Heating beds are essential for challenging materials.

- shell: Mandatory ABS, ASA, nylon and large PETs that are highly recommended for ease drafts and maintain stable temperatures.

Phase 2: Print – Hire Fleet Court!

- Machine calibration: Ensure that the bed is upgraded to laser precisely. Calibrate the extruder E steps to make it flow perfectly. Test the temperature tower of each new filament to find the best location. A small calibration cube/target marker saves time wasted hours first.

- Religious Surveillance: Start printing and watch the first 5-10 layers closely. Use remote monitoring tools (Baba Pulin, webcam) to focus on long prints. Regularly check for layer offsets, spaghetti monsters, catastrophic capital ships on catastrophic or adhesion failures.

- environment: Keep the printer away from drafts. Maintain the shell temperature of the temperature-sensitive material.

- Patience is patriotic: Large models take days or even weeks. Enter it. Quality cannot be rushed. Ensure power stability – Consider the amount of prints in hostile territory overnight UPS backup.

Phase 3: Post-processing – The best in polishing empire

This stage separates the toys from meticulous entertainment. Don’t skip this step!

- Support removal:

- FDM: Carefully shear and peel the support. Use a rinse cutter and hobby knife. Patience prevents damage to surface details.

- Resin: Strategic support for tailoring. Use high sandpaper to carefully chunks of sand.

- Rally and Join:

- First dry! Never believe in the grid. Test fits all parts before applying any glue. Sand mating if needed.

- Adhesive:

- PLA/PETG: Ca glue (super glue) or special plastic glue. Epoxy is strong but messy.

- ABS: ABS slurry (ABS wire dissolved in acetone) produces stronger welding than the plastic itself.

- Resin: Ca glue or special resin glue works very well.

- strengthen: For large FDM hulls that bond large FDM shells together, add internal reinforcement to the joints – metal rods and embed epoxy/millets drilled/casted into the structure in aligned channels. Large-scale structural integrity is crucial.

- Surface finish – Accurate charm:

- Grinding: The key to professional completion. For the main seams and layer lines start to roughen (120-220 particle size). Progress to finer gravel (400, 600, 800, 1000+) for smooth surfaces. Your fingers will hurt and the result is worth it.

- Filler: Use high-quality styling putty (e.g., Tamia White Putty, Squadron Green Things, Bondo) to fill layers, seams, pits, pits and print artifacts. Apply carefully, the sand is smooth. Multiple cycles are standard. Used for engineering plastic or metal printing GreatOur post-processing team leverages advanced techniques and fillers for flawless surfaces before painting.

- start up: Key steps! The startup reveals surface defects. Use a grey filler primer. Apply a light coat. If the defect reappears, sand between the coats. Repeat until smooth justice is achieved. The third layer can achieve good basic color coverage. Remember: any imperfections you see in the primer will be magnified 10 times in the last layer.

- painting: The right tools are needed. Primer; color masking (for hull panels and plating); careful lighting, sensor dome, hand-painted engine; panel lining with washing; dry brush highlights; decal application. Demand excellent detail work and care. For those who demand perfection on metal prints, professional painting and clear coatings are the ideal successors to our professional work, bringing this model to the top state.

Conclusion: Bring order into the Milky Way, one layer at a time

3D printed star destroyers are marathons, not sprints. It requires meticulous planning, proficiency in materials, diligence in printing and huge post-processing efforts. However, the reward is unparalleled.

Whether you choose to solve this ambitious project at home, pushing printers and skills to the limits of PETG or resin, or dreaming of using huge museum works in aviation grade metals such as titanium or through industrial selective laser melting (SLM), SLM (SLM), SLM (SLM), SLM), (SLM), SLM (SLM), Great Ready.

As a leading rapid prototyping manufacturer with advanced SLM equipment and deep expertise in solving complex manufacturing challenges, we are unique in turning your most ambitious vision of scale modeling into reality. Apart from printing, our comprehensive one-stop post-processing service ensures your Star Destroyer reaches its final, breathtaking finish – perfectly smooth surface, meticulous assembly and ready for professional painting or display. Visit our website today to see how we bring your greatest empire ambitions to life.

FAQ: Your burning question has been answered

-

What is the best material for printing a star destroyer at home?

- Balance (most users): Petg. Stronger than PLA, less warping than ABS, and easier to print than nylon. Perfect for the hull part. Good color choices exist.

- For the final details: Resin. Unparalleled guns, towers and gree bones. Best for smaller models or in combination with plastic hulls.

- Anti-appearance/weather resistance: asa. Needs a closed printer and ventilation, but looks like high-end plastic/less brittle.

- avoid: PLA for any large structural parts – distortion and weakness are serious risks.

-

How do I prevent the long hull from bending?

- FDM Revolution: Case is essential (mandatory for ABS/ASA). High-quality established surface adhesion (Magigoo, LiseNeer, etc.).

- Bed temperature: Ensure proper temperature stability.

- Print slowly: The first layer is slow, heat is the key. Edge or large raft helps.

- Internal reinforcement: Within the hull section, low fillers are used, but the metal rod/carbon fiber channels are designed to anchor the structure and prevent bending over time. Industrial SLS has no problem with distortion, even on a large scale.

-

After assembling the parts, the surface seams are terrible. help!

- This is the main obstacle. Detailed dry fittings and sanding mating edges are crucial before bonding.

- Using modeling putty generous Fill the seams.

- The sand gradually becomes thinner and gravel.

- Main;sand; use more putty if needed; repeat until it is out of sight. It is labor-intensive, but is inevitable for large prints.

-

What 3D printer do I need?

- Large FDM: Corexy printers (e.g. Voron, rat rig) or large Cartesian (e.g. CR-10 S5, CREALTY K1, BAMBU LAB X1 CARBON) 300x300mm bed or larger, recommended for larger models with fewer parts for substantial.

- Highly detailed resin: Any mainstream LCD/MSLA resin printer (Elegoo Saturn series, Anycubic Mono X, Phrozen Sonic) is suitable for superstructure parts. Even the largest consumer printers at present, each carrier can only build about one foot.

- A bigger dream? : For star destroyers over ~70-80 cm, professional printing services with SLS or fusion powder bed fusion machines (including SLM for metals) are required for the strength and lack of warping required to reach this scale. That’s where Great Truly shine.

-

How to get super details and chromed metal finish?

- detail: This is mainly achieved by printing resin for these components. Excellent model design and support are crucial. Post-treatment and carefully polished/polished.

- Chromium/Metal: Professional finishing is required: high-gloss paint jobs, followed by technologies such as Alclad Metal Pacquers, Buffing or Advanced spray guns. For metal SLM printing, professional polishing or electroplating provided by services such as such Great Creates a stunning durable metal finish with plastic.

- Should I design my own model?

- Unless you are an expert 3D modeler with a lot of experience in CAD/digital engraving Printabilitywe strongly recommend not starting from scratch. The complexity is huge. Leveraging existing, highly acclaimed STL files designed specifically for printing is the actual path for most builders. Focus on printing, assembly and finishing perfection.