introduce

In the dynamic world of manufacturing, rapid prototyping has revolutionized how the industry brings ideas to life. An excellent solution in this space is Student 3Dleverages state-of-the-art technology to transform digital design into a service for functional metal parts. As a professional rapid prototype manufacturer, Great Basic Student 3D has its advanced features that provide accuracy, speed and reliability. This review explores what makes Cadet 3D a game-changer and how Greatlight’s expertise can take it to industry-leading standards.

Rapid Prototyping The Rise of Students 3D

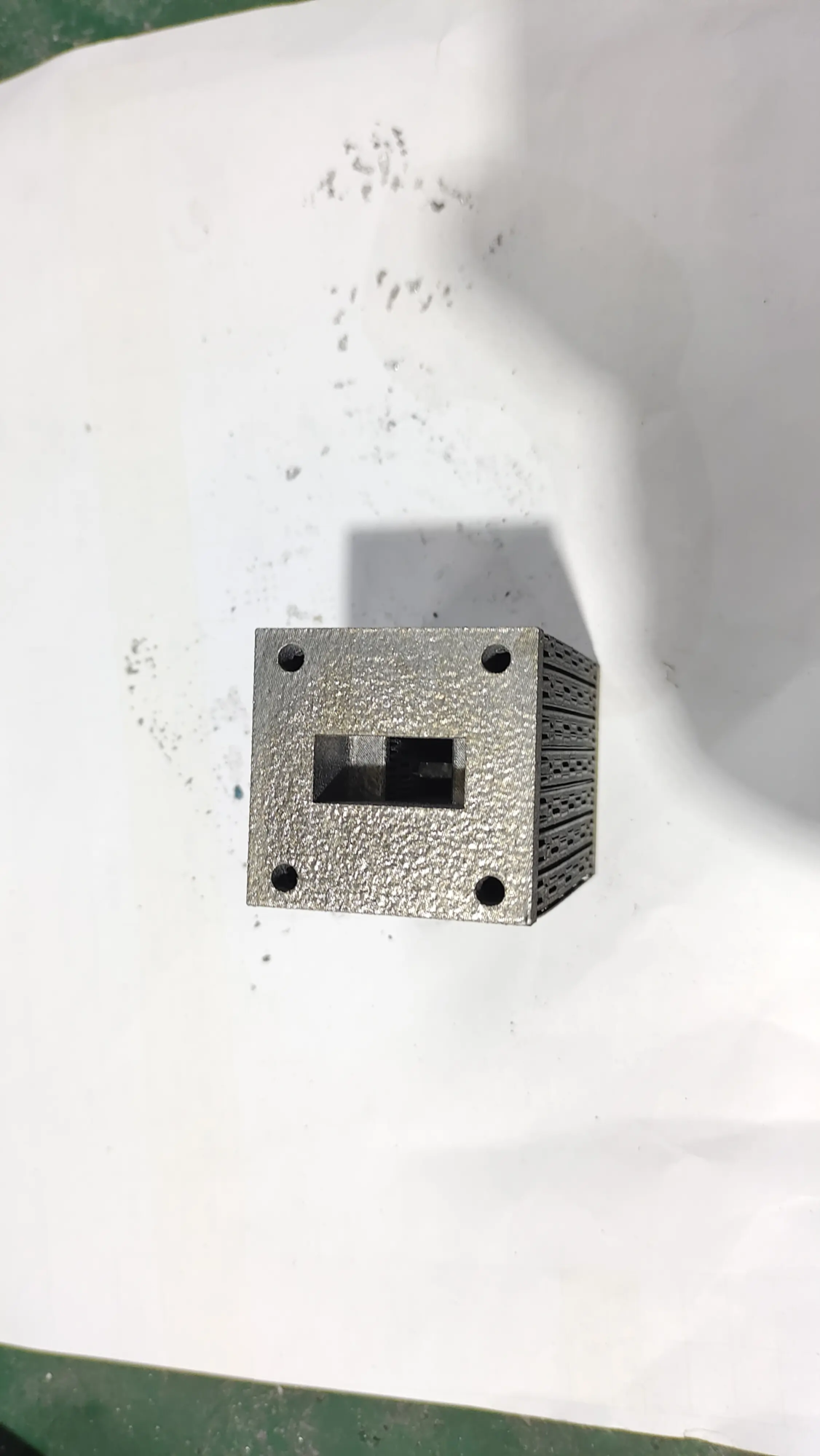

Cadet 3D is not only a service, but a comprehensive approach to rapid prototyping of metals. Designed for engineers and innovators who demand high fidelity and durability, it bridges the gap between concept and functional testing. Traditional prototyping methods, such as CNC machining or injection molding, often involve high costs and lead times for complex geometries. Students use these obstacles in 3D Selective laser melting (SLM)an additive manufacturing process that constructs parts layer by layer from metal powder. This ensures complex internal structures and lightweight designs that cannot be achieved by traditional methods.

Core advantages: Technology and expertise

At the heart of Cadet 3D is Greatlight’s state-of-the-art SLM 3D printer. These systems perform well in production Completely dense metal parts Mechanical properties are comparable to those of traditionally manufactured components. Key advantages include:

- Material versatility: Cadet 3D supports materials such as titanium, aluminum, stainless steel and Inconel, and offers options for custom alloys.

- Complex geometric shapes: From lattice structure to integrated components, it can handle impossible designs through subtraction.

- Speed and accuracy: Parts are manufactured within a few days with tolerances up to ±0.1 mm.

Greatlight further enhances Cadet 3D Integrated post-processingincluding heat treatment, CNC finish and surface coating. This end-to-end service eliminates logistical headaches and ensures that parts meet functional requirements, whether for aerospace, automotive, or medical applications.

Solve real-world prototype challenges

Student 3D goals are key pain points in product development:

- Time of listing: Reduce the prototype cycle from weeks to days to accelerate R&D.

- Cost-efficiency: Avoid instrument investment; economically produce small batches or one-time.

- Iterative design: Quickly test and perfect parts without material waste.

For example, automotive customers use Cadet 3D to create lightweight, heat-resistant turbine components. Greatlight optimizes the design of SLM, post-processed through Shot Peening, and provides a functional part within 72 hours, saving 40% of development costs.

Why choose Greatlight for students 3D?

Greglight’s position is China’s fastest prototype company, which is due to:

- Mastery of technology: Engineer with deep expertise in metallurgy and additive manufacturing.

- quality assurance: Strict process monitoring and ISO-compliant inspection.

- Scalability: From prototype to low volume production.

Their customer-centric approach includes material customization and speeding up timelines, which is ideal for urgent projects that require precisely accurate at competitive prices.

in conclusion

Cadet 3D, powered by Greatlight’s advanced SLM technology, redefines rapid prototyping of metal parts. It combines agility, innovation and quality, which is for the industry that navigates today’s fast-paced product cycles. By integrating design freedom with powerful post-processing, Greatlight provides a seamless solution from R&D to ready components. For engineers and innovators seeking to transcend space competition, Cadet 3D is more than an option. This is the new standard for precise prototyping.

Start today

Ready to turn your concept into reality? access Great Quote your custom project. With fast turnaround and material flexibility, your next breakthrough is clicking.

FAQs about Students 3D and Greatlight

Q1: What is the typical delivery time for the Student 3D project?

A: Simple prototypes are shipped within 3-5 days. Complex parts with post-treatment (e.g., polishing, coating) take 7-10 days. Urgent requests were accommodated.

Q2: How complicated is the CAD design of Cadet 3D?

A: SLM supports extreme complexity: undercut, hollow parts and organic shapes. Our team reviews the designs to ensure manufacturability.

Question 3: Does the trainee 3D support food grade or medically certified materials?

A: Yes. We offer medical grade titanium (Ti6al4v Eli) and stainless steel (316L), both Biopompatiby and ISO 10993 certified.

Question 4: Can I order multiple post-processing services together?

Answer: Absolute. Common pairings include stress bias + CNC machining or anodizing + laser engraving. Discuss the requirements with our experts.

Q5: Is Student 3D cost-effective for small batch production?

A: Yes – ideal 1-1,000 units. No tool cost and minimal material waste makes it comparable to traditional methods.

Question 6: How does Greatlight ensure the quality of parts?

A: We use in-situ monitoring, CT scans of internal integrity and coordinated measurement machine (CMM) dimensional accuracy during the printing process.

Q7: Is it possible for design modification to occur after orders?

A: Changes are accepted within 24 hours after the order is placed. Later modifications may incur expenses, but are usually feasible.

Question 8: Can I provide my own alloy powder?

Answer: Customized materials are welcome. We first verify powder performance and compatibility with SLM systems.

Q9: Which file formats do you accept CAD design?

A: .stl or .step files are preferred. Include key dimensions and finish requirements in your notes.

Q10: Is there a minimum order value?

Answer: There is no minimum. We offer projects of all sizes – from single-type prototypes to mass production.

For further inquiries, please contact Greatlight’s engineering team – your dedicated partner for accurate prototyping.