Building a new world: the key "title" Application of 3D printers in Mars transformation

The dream of humans walking, working and thriving on Mars is no longer confined to science fiction. As space agencies and private companies around the world accelerate plans for Mars’ persistence and eventual colonization, monumental engineering challenges are taking center stage. Transporting massive infrastructure millions of miles is both expensive and impractical. The answer lies in In-situ Resource Utilization (ISRU) – Utilizing the Red Planet’s own materials. What is becoming ISRU’s cornerstone technology is 3D printing. But not just any printer—Mars construction requires specialized machines with unique, critical functions "title," Each plays a unique role in the bold effort to transform the Red Planet.

The ruthless canvas of Mars: Why 3D printing is non-negotiable

Imagine a world devoid of breathable air, with temperatures well below zero, bathed in intense radiation, with a thin layer of toxic air, and covered with a fine abrasive regolith. This is Mars. Establishing any permanent habitat requires overcoming these significant obstacles:

- Logistics nightmare: Shipping every nut, bolt, and habitat module from Earth would be costly and inefficient.

- Harsh environment: Structures must withstand extreme thermal cycles, radiation, low pressure and sand and dust storms.

- Resources are scarce: The initial mission cannot rely solely on imported supplies; sustainability requires the use of local materials (regolith, atmosphere).

- Complexity and speed: Given the risks to human life, construction must be fast, adaptable, and often autonomous.

3D printing, especially Metal Additive Manufacturing (AM) using technologies such as Selective Laser Melting (SLM)become a game changer. It can:

- Made on demand: Complex structures are built using local materials (regolith simulants are initially injected with polymers or adhesives, and subsequently the regolith may be sintered or metal machined).

- Design freedom: Create optimized complex geometries to achieve strength-to-weight ratios, radiation shielding, and thermal management that go far beyond traditional methods.

- Reduce waste and quality: Use only the materials you need.

- Remote and automated operation: Pre-positioning infrastructure or buildings is critical for times of danger.

- Repair and maintenance: No need to wait for supplies to manufacture replacement parts.

Important List: Critical 3D Printing "title" Mars terraforming

To terraform Mars, we envision a variety of professional 3D printers, each with a specific mission. Think of them as versatile robotic pioneers with unique careers critical to planetary engineering.

-

Habitat Builder: Survival Master

- mission: Build pressurized, radiation-proof habitats where humans can live and work safely.

- Processing materials: Mainly regolith-based materials – sintered regolith concrete, regolith mixed with polymers/resins, or possibly processed Martian minerals/metals once mining infrastructure exists.

- Technical focus: Large gantry or robotic arm systems using binder jetting, extrusion deposition or potentially large format sintering.

- importance: Providing essential shelter for human existence. Structures can contain integrated life support channels, insulation and meteoroid protection.

-

Oxygen Generator: Air Smith for the Red Planet

- mission: Produce vital, breathable oxygen (O2) directly from the Martian atmosphere.

- Processing materials: Carbon dioxide (CO2) is extracted from the Martian atmosphere through an electrolysis or catalytic process and integrated into the printers/systems it manufactures.

- Technical focus: The highly specialized system uses high-precision DMLS/SLM to print complex chemical reaction chambers, electrolytic cells, catalysts and storage vessels for chemically resistant metals and alloys. Metal additive manufacturing is critical for miniaturization, complex fluidics and sealing.

- importance: Directly addressing the most critical survival need: breathing air. Important precursors to terraforming, increasing atmospheric pressure and oxygen content on geological time scales.

-

Infrastructure Builders: Architects of Civilization

- mission: Construct basic non-pressurized infrastructure – landing pads, roads, fallout shelters, garages, utility tunnels, berms, foundations for large equipment.

- Processing materials: Raw or minimally processed weathering obtained by sintering, compacting, or extrusion of weathered concrete.

- Technical focus: Heavy-duty, rugged printer capable of working outdoors in sandstorms. Large-scale extrusion, large-area sintering/binder spraying. Typically autonomous or remotely operated.

- importance: Enable ground operations, transport, protect critical assets, and build the physical framework of the colony.

-

Tool Makers: Guardians of Progress

- mission: Manufacture of tools, spare parts, jigs, fixtures, scientific instruments and mechanical components necessary for all operations in situ.

- Processing materials: Primarily metals for functional parts (shipping powder precursors such as titanium, aluminum, steel); later there may be recycled materials or locally sourced metals. Polymers for Tools/Jigs.

- Technical focus: Precision SLM/DMLS (metal), SLS (polymer), FDM (polymer). High resolution and reliability are critical. Smaller format printers are typically used within habitats.

- importance: Eliminating significant downtime waiting for earth replacement. It is crucial for bee colonies to be resilient and adapt to unforeseen challenges.

-

Soil Engineer: Green Cultivator

- mission: Create structures and systems that support agriculture and soil creation, such as greenhouse frames, hydroponic arrays, soil containment beds, and potential soil "conditioning" Equipment that processes regolith into something useful for plants.

- Processing materials: Metals and polymers for greenhouse structures and systems; regolith simulation treatments for soil generation experiments.

- Technical focus: A combination of metal additive manufacturing for structural components and potential polymer/biocompatible printing for specialty elements. Larger extrusion for soil containment.

- importance: Necessary for sustainable food production and the initiation of biological processes (introduction of microorganisms, plants) that are critical for long-term terraforming.

- Bioprinters: Life Engineers

- mission: (Long-term) Possibility of printing biomaterials, tissue engineering scaffolds (for medical needs, perhaps eventually engineering microorganisms/plants), or integrating biocompatible elements into the structure.

- Processing materials: Bioink containing living cells, biocompatible polymers.

- Technical focus: Professional bioprinting platforms require microscopic precision and a controlled environment (maintaining cell viability even on Earth is complex!).

- importance: The potential for future advanced medical support and the potential for seeding life on Mars in controlled terraforming experiments.

GreatLight: Earth expertise paves the way to Mars

While the Martian landscape is unique, the core technology of these pioneering printers is being honed here on Earth. exist huge lightleader Precision Rapid Prototyping and Metal Additive Manufacturingwe employ cutting-edge technologies that are critical to making these Mars dreams a reality.

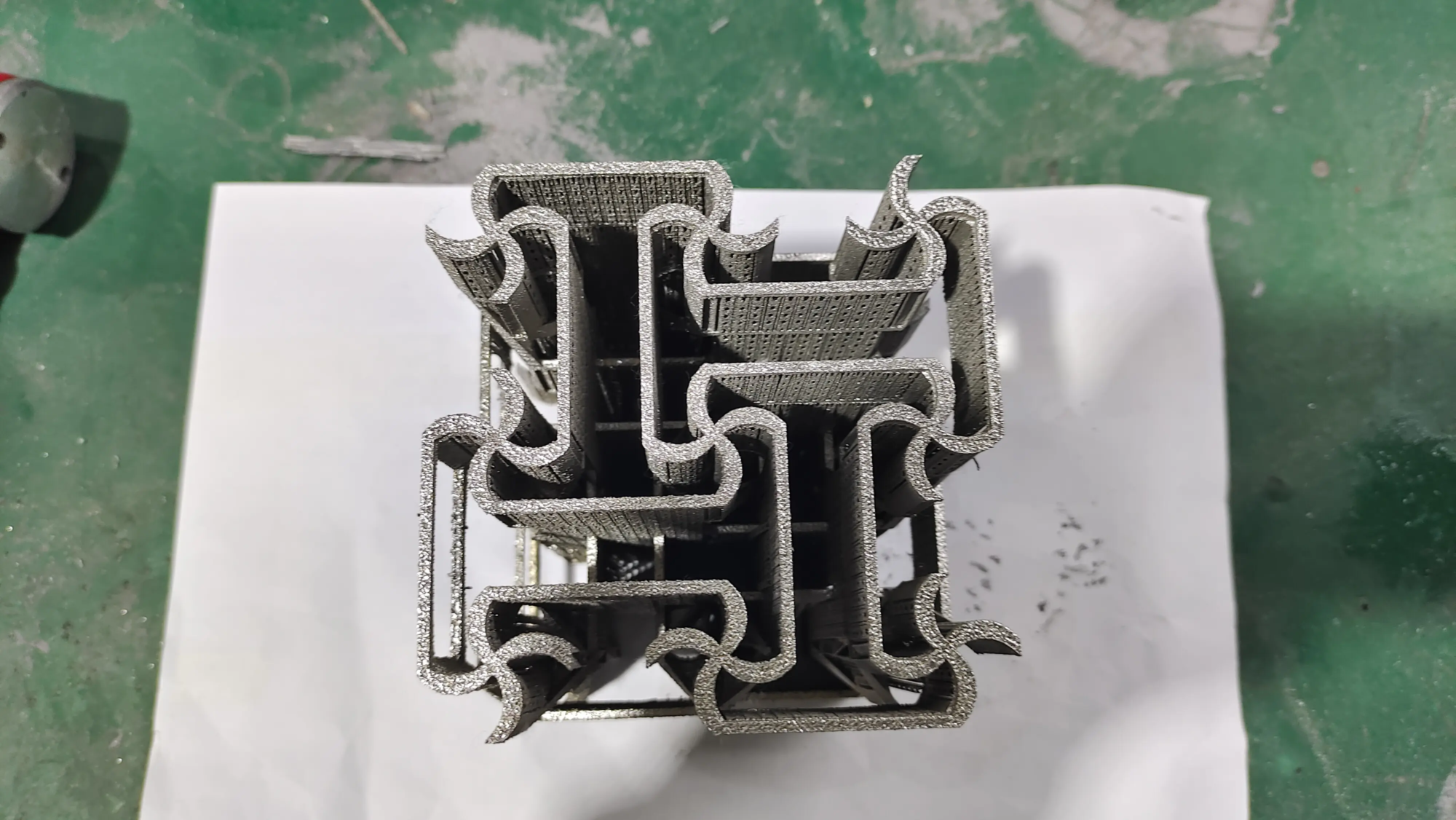

- Advanced SLM/DMLS expertise: We have an extensive fleet of modern aircraft Selective Laser Melting (SLM) The printer enables us to produce complex, high-strength metal parts from challenging aerospace-grade alloys such as titanium (Ti6Al4V), Inconel and aluminum. This capability for complex, reliable metal parts reflects the precision required within manufacturers of mission-critical space hardware and oxygen concentrators or reactor tools.

- Comprehensive one-stop solution: In addition to 3D printing, we also provide the necessary Post-processing and finishing services – Including CNC machining, heat treatment, shot blasting, polishing and surface treatment. This ensures the components meet the tight dimensional tolerances, surface finish and material properties required for the extreme space environment – qualifications that are directly transferable to Mars infrastructure.

- Material Versatility and Customization: We specialize in handling a variety of metal powders and can handle complex custom projects. This reflects the adaptability required for Mars missions, where systems must operate with available resources and solve unique engineering problems.

- Prototyping speed and accuracy: as top Rapid prototyping company from Chinawe understand the need for speed and iteration. Our ability to rapidly produce and refine complex prototypes is fundamental to developing and testing advanced additive manufacturing systems heading to Mars.

Conclusion: Printing the Basics of a Second Home

Terraforming Mars is an endeavor that spans generations, but the first steps depend critically on powerful, versatile, and reliable 3D printing technology. this "title" The designated roles – Habitat Builder, Oxygen Generator, Infrastructure Builder, Toolmaker, Soil Engineer – represent the basic robotic capabilities needed to establish a foothold and begin planetary engineering. Each utilizes the principles of ISRU and advanced additive manufacturing to address a critical survival or growth need.

The journey to Mars begins with innovation on Earth. Gretel is proud to be at the forefront Precision metal additive manufacturingprovides advanced SLM printing and integrated finishing services to prototype these interstellar pioneers and potentially help produce the complex components required. We are committed to solving complex manufacturing challenges with speed and precision – qualities necessary for terrestrial and extraterrestrial exploration.

As humanity heads towards the red planet, 3D printing is more than just a tool; It is the indispensable builder, engineer, chemist and creator that turns the dream of Mars into a tangible, habitable reality.

Frequently Asked Questions (FAQ) about Mars Terraforming and 3D Printing

-

Q: What is "Transforming Mars 3D Printer Title" What does it mean?

- one: This refers to the different roles or specialized functions that different types of 3D printers need to fulfill to achieve the long-term goal of terraforming Mars. each "title" (e.g., Habitat Builder, Oxygen Generator) represent a class of printers designed for specific critical tasks using Earth’s resources.

-

Q: What are the main advantages of using 3D printing for Mars colonization?

- one: Key benefits include:

- In-situ Resource Utilization (ISRU): Using local Martian regolith and atmosphere greatly reduces the mass and cost needed to launch everything from Earth.

- Design freedom: Create complex, optimized structures not possible with traditional architecture.

- Automation and remote operation: Construction is permitted prior to crew arrival or during hazardous conditions.

- Made on demand: Production of spare parts and tools in situimprove task flexibility.

- Reduce logistics and waste: Only raw materials or printer feed are transported; minimizing on-site waste.

- one: Key benefits include:

-

Q: What materials can be 3D printed on Mars?

- one: Initially, the focus is on rich resources:

- Regolith: Weathered concrete is sintered (hot melted) into a solid form for use with a binder or processed into large structures.

- Atmospheric carbon dioxide: Processed into oxygen via printing reactor.

- Shipping powder: Metal powders (titanium, aluminum, steel) for critical tools and precision parts via SLM. Polymers used for less important items. Techniques for extracting and processing native Martian metals may evolve over time.

- one: Initially, the focus is on rich resources:

-

Q: Can metal be 3D printed on Mars?

- one: Yes, but initially metal powders pre-shipped from Earth were used. Selective Laser Melting (SLM) is the leading candidate technology. It requires a lot of energy and a controlled (possibly pressurized) environment within a habitat or enclosure. Processing native Martian ores into usable metal powders is a more distant prospect.

-

Q: How does GreatLight’s expertise on Earth relate to applications in space?

- one: Huileite’s core competencies—— High-precision SLM metal printinghandling complex geometries with demanding alloys, rigorous Post processing and finishingand rapid prototyping – Directly related to developing space hardware:

- Prototype components of the Mars printer (reaction chamber, custom tooling, structural components).

- Use qualified materials and processes to manufacture critical aerospace components.

- Solve complex engineering challenges requiring custom metal parts.

- Delivering the speed and accuracy required for iterative spatial technology development.

- one: Huileite’s core competencies—— High-precision SLM metal printinghandling complex geometries with demanding alloys, rigorous Post processing and finishingand rapid prototyping – Directly related to developing space hardware:

-

Q: Isn’t terraforming Mars science fiction?

- one: Achieving a fully Earth-like planet may be beyond our current technology and timescales (centuries or millennia). However, the first steps Actively researching and developing in-situ fabrication using 3D printing to build habitats and life support for human groups (e.g., NASA’s Centennial Challenge, ESA’s initiatives). this "title" Represents fundamental technology for sustainable development for printers presenta necessary prerequisite for any long-term terraforming effort.

- Q: Can GreatLight help with aerospace or advanced applications related projects?

- Answer: Of course. Our advanced SLM 3D Printers and Comprehensive Machining Services Designed to meet the demanding requirements of the aerospace, defense, medical and high-tech industries. We specialize in custom rapid prototyping and low-volume production of complex, high-performance metal parts. Please contact us to discuss your specific precision machining and component needs.