Getting Started with TEVO Printers: Your Comprehensive Setup Guide

Now that you’ve dived headfirst into the exciting world of 3D printing, your shiny new TEVO printer has arrived! Congratulations! TEVO printers are known for their excellent value proposition – packing powerful technology into kits to facilitate learning and customization. However, the process from unboxing these components to producing your first high-quality print requires careful setup. This guide will walk you step-by-step through the process, ensuring you have a solid foundation for countless successful prints to come. Remember, patience and attention to detail during setup are crucial to unlocking TEVO’s full potential.

Step 1: Unboxing and Inventory – Start with the Right

Carefully unpack each component. Arrange them methodically in a clear workspace. Do no Discard all packing materials until you are sure you have everything! Please carefully refer to the official packing list (or BOM – Bill of Materials, if not included, which can sometimes be found online). Check each item on the list – frame extrusions, motors, electronic components (circuit boards, power supplies, screens), hot end components, print boards, belts, pulleys, bolts, nuts, wires and other hardware. Missing parts happen, but catching them early can simplify the problem-solving process.

Step 2: Assemble the core structure

Most TEVO kits arrive partially assembled. Now focus on building the main framework:

- Frame assembly: Connect the aluminum profiles strictly according to the instructions. Use the correct bolts and make sure everything is square. Carpenter Square is priceless here. Misaligned frame angles will affect future print quality! Tighten the bolts securely but avoid stripping the aluminum threads.

- Movement components: Mount the stepper motor firmly to the designated position (X, Y, Z axis). Install the rod/bearings carefully – first clean the rod with isopropyl alcohol (IPA), then lightly lubricate the bearings according to manufacturer specifications. Avoid binding!

- Shaft belt: Properly connect the timing belt to the motor pulley and idler pulley on each shaft. Make sure they are tight but not too tight. Use the belt tensioner correctly.

Step 3: Integrate Electronics

Take electrostatic discharge (ESD) precautions when handling electronics – keep sensitive components grounded:

- Install: Use the provided hardware to securely connect the main control board (such as an Arduino-based MKS Gen or similar device), touchscreen (if applicable), and power supply unit. Make sure there is adequate air circulation around the power supply.

- Motor connection: Connect the stepper motors to the marked ports on the motherboard (X, Y, Z, Extruder/E) using typical color-coded connectors. If you’re not sure, look up the circuit board schematic online.

- End stop/sensor connection: Accuracy requires knowing where the axis starts. Install the limit switch or proximity sensor correctly and wire it securely.

- Hot end assembly: Mount the entire hot end (heater block, nozzle, heat sink) and parts cooling fan to the X-axis bracket, connect the heater box and thermistor wires very carefully. Make sure there are no short circuits. Connect parts cooling fan. Use zip ties to securely connect wiring to avoid catching moving parts.

- Heated bed: If equipped, connect the wiring securely. Pay attention to the dynamic movement of the bed! Use the supplied flexible cable chain/strain relief or temporary solution.

- Final wiring: Use zip ties to methodically route all wires along designated paths No Prevent any axis from moving freely. Double check polarity if applicable (motors are usually polarity independent, but fans/heaters/thermistors are not!).

Step 4: Power-on initialization

- Double check: Before plugging in, carefully check all electrical connections, especially heater and thermistor wiring. Improperly wired thermistors can cause thermal runaway, creating a serious fire hazard.

- strength: Now only connect the power input cable. power ups!

- Firmware communication: Make sure the touchscreen/monitor powers up correctly.

- Motor direction: Use the printer menu to briefly test each axis individually. Move the nozzle +10mm in the X, Y, Z directions. Viewing direction – it should match the expected movement (right, front, up). If moving backward, reverse the motor connector on the motherboard. Do the same for the extruder motor. Test the homing function (G28 command or via menu).

- Temperature verification: Preheat the nozzle and bed to common temperatures (e.g., PLA settings: 200°C nozzle, 60°C bed). Use an infrared thermometer (if available) to roughly verify that the nozzle has reached the commanded temperature. Crucially, ensure that the nozzle does not continue to heat uncontrollably – if it is told to heat to 200°C, it should cycle/stable around that value.

Step 5: Precise calibration – the key to great printing

- Bed Leveling/Transportation: This is Paramount! Automatic leveling (BLTouch, sensor-based) usually requires manual verification initially using the paper method (you should feel slight friction as the paper under the nozzle slides across the bed). Methodically adjust the base screws. Most TEVO printers require manual leveling. It takes practice – be patient!

- Adjust Z offset: After leveling, set the first level height. This is the distance between the nozzle tip and the build plate "Z=0" (achieved by homing) when just holding the leveling paper. Fine-tune with printer firmware offset settings or base screw final adjustments. Strive for perfection "flatten".

- Extruder Calibration (ESTEPS): Crucial for precise filament extrusion. Mark the filament 120mm above the extruder entrance. Extrude 100 mm via Printer Menu/Firmware/G Code command. Measure the actual wire feed length (should be exactly 100 mm). If you only feed 90mm, calculate: NewSteps = (OldSteps * 100) / 90. Update the ESteps value. Retest until accurate.

- PID tuning: Achieve stable temperatures without overshoot/drift (preventing print artifacts such as spots/zits). Look under the printer menu for PID Autotune or send a specific G-code command. Required after any major hot end changes.

Step 6: Slicer Setup and Your First Print

Install your favorite slicer (Cura, PrusaSlicer, Simplify3D). Download a validated baseline slicer profile that’s right for you precise TEVO model (see TEVO Forum/GitHub/etc.). Minimum modifications:

- Set the filament diameter accurately.

- Confirm the nozzle diameter setting (usually 0.4mm).

- Start with basic PLA configuration file parameters.

- Slice a small calibration print (Benchy is popular).

- Transfer G-code files (SD card, USB or network).

- Print! Closely monitor the critical first layer – adjust real-time Z offset/movement if needed.

Conclusion: Mastering the basics opens the door to creativity

Successfully setting up a TEVO printer is a rewarding achievement. The diligence you put in now will directly translate into superior print reliability, dimensional accuracy, and minimization of frustrating breakdowns on the production line. Using setup as part of a DIY learning journey can demystify your machine—essential knowledge for later troubleshooting. Mastering bed leveling and calibration allows you to confidently tackle a variety of filigree and intricate projects.

When Precision Moves Beyond DIY: Enter GreatLight Prototyping

While DIY printers like TEVO can unleash incredible creativity and learning capabilities, professional applications often require unparalleled precision, complex geometries, engineering-grade materials, tight tolerances, and rugged finishes that most hobby setups can’t deliver. This is where working with a professional rapid prototyping partner becomes extremely valuable.

GreatLight Rapid Prototyping Services – Your partner that goes beyond DIY

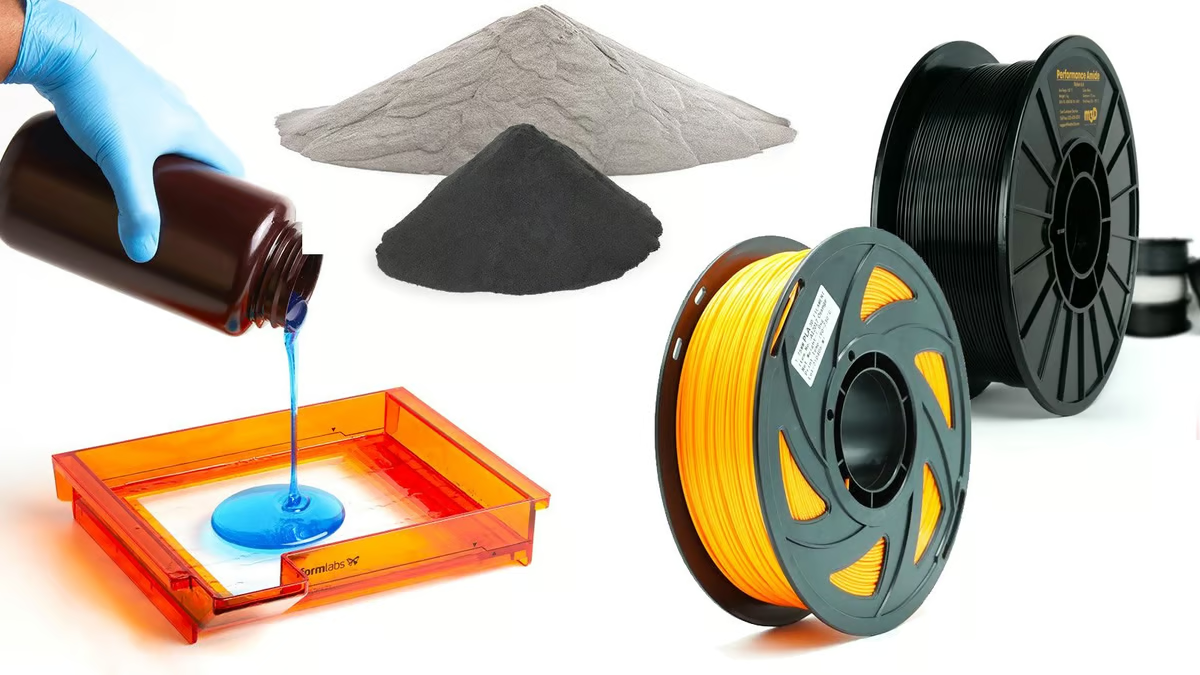

For engineers, designers and businesses in need of industrial-grade 3D printed parts, GreatLight stands out. We utilize advanced technology, specifically industrial Selective Laser Melting (SLM) metal 3D printers, to deliver complex metal prototypes not possible on Fused Deposition Modeling (FDM) machines such as TEVO. Our expertise effectively solves complex metal rapid prototyping challenges.

Beyond printing:

GreatLight excels as One stop solution:

- Advanced Materials Expertise: Rapidly process a wide range of metals, polymers and composites. Provide customized solutions.

- Precision Machining: Combining additive manufacturing (3D printing) with precision CNC machining to achieve unparalleled dimensional accuracy and surface finish.

- Comprehensive finishing: professional polishing, staining, plating, painting, heat treatment – tailored to the final application requirements.

- Unrivaled price/performance: Deliver superior prototyping solutions quickly and at a competitive cost.

Let GreatLight transform your complex CAD designs into tangible, functional, market-ready prototypes with unparalleled accuracy and speed – completely bypassing setup hassles. Explore custom rapid prototyping quotes here

FAQ: TEVO Setup and More

Q: Why can’t my TEVO printer start up?

A: Check: The power cord connections at both ends (printer and wall). Power voltage selector switch (110V/220V) –