The Dawn of a New Dimension: Embracing the Next Era of 3D Printing

The manufacturing industry is undergoing a dramatic transformation, driven by growing advances in additive manufacturing, commonly known as 3D printing. We are moving beyond our initial fascination with plastic trinkets and prototypes into a transformative era where complex, durable, and mission-critical metal parts are being manufactured layer by layer. welcome to The 3D Printed Universe: The Next Eraa paradigm defined by unprecedented capabilities, materials diversity and industrial applications. This era has unleashed possibilities once considered science fiction, fundamentally reshaping the way we design, iterate and produce.

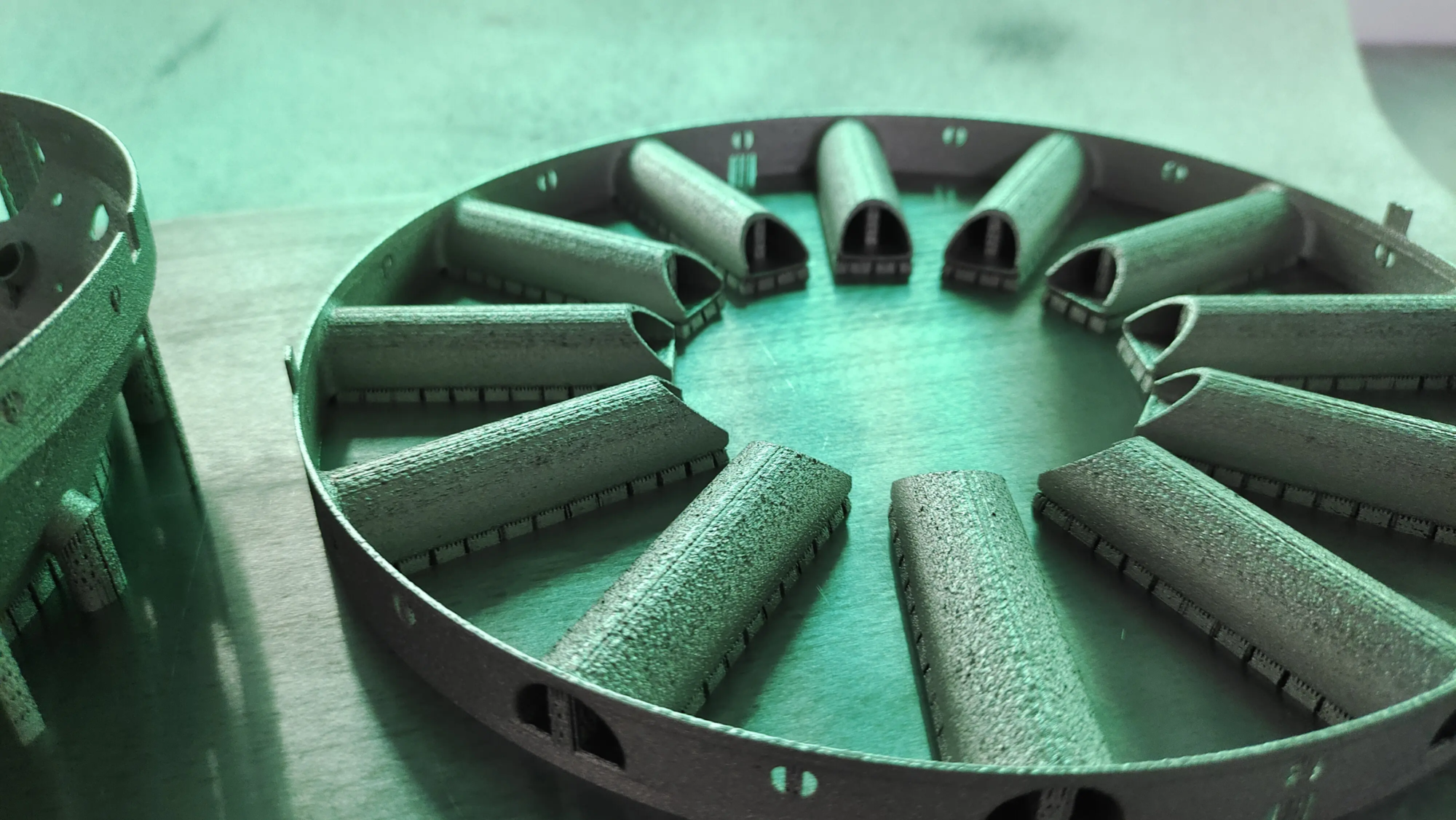

The core of this revolution lies in Metal Additive Manufacturingespecially techniques like Selective Laser Melting (SLM). SLM harnesses the power of a focused laser to carefully melt fine metal powders (titanium alloys, stainless steel, aluminum, Inconel, tool steel, etc.) to create fully dense parts with complex geometries not possible with traditional machining or casting. This leap enables engineers to:

- Unconstrained design: Enable optimized lightweight structures such as internal lattices, complex internal channels for cooling or fluids, and organic shapes dictated by function rather than manufacturing constraints.

- Accelerate innovation: Greatly shorten the prototype design and product development cycle. Radical designs can go from digital concept to physical testing in days instead of months.

- Production on demand: Promote the economical operation of small batch production, enable mass customization and reduce warehousing costs.

- Create a one-piece structure: Consolidates multiple assembly parts into a stronger assembly, increasing reliability and reducing potential points of failure.

Leading the way: GreatLight – your industrial rapid prototyping partner

Navigating the complexity of metal 3D printing requires more than advanced hardware; it requires deep expertise, rigorous process control, and a commitment to solving complex engineering challenges. where is this huge light Rise as a leader and firmly establish yourself as a One of China’s leading rapid prototyping companies.

GreatLight differentiates itself by offering comprehensive end-to-end solutions for high requirements Rapid prototyping of metal parts and production:

- Advanced SLM expertise: Our factory features state-of-the-art SLM 3D printers and industry-leading production technology. We have a deep understanding of the laser parameters, powder handling, inert atmosphere control and thermal management required to produce parts with excellent mechanical properties, dimensional accuracy and surface integrity.

- Problem Solving Master: We specialize in solving complex challenges. Whether achieving fine feature resolution, managing stress and deformation in large structures, optimizing support structures or ensuring the airtightness of fluid components, our experienced engineering team works with customers to design effective solutions.

- One-stop post-processing and finishing: The original 3D printed part is just the starting point. GreatLight provides seamless integration of necessary post-processing, including precision CNC machining of critical interfaces, stress relief, heat treatment (annealing, aging, HIP), meticulous support removal, complex surface finishing (machining, polishing, sandblasting, electropolishing) and special coatings customized to application requirements.

- Unparalleled material customization: We know that materials are the foundation. In addition to a broad range of standards (AlSi alloys, Ti6Al4V, 316L/304L stainless steels, maraging steels, Inconel, copper alloys), GreatLight specializes in customizing material blends to unique customer specifications to achieve tensile strength, heat resistance, weight reduction or biocompatibility. We work closely to identify or develop the best materials your application.

- Speed and precise focus: "quickly" It’s ingrained in our DNA. We optimize our processes to achieve extremely fast turnaround times without compromising accuracy or quality. Our stringent quality control protocols ensure that every part meets the strict dimensional tolerances and performance benchmarks required by the aerospace, automotive, medical, robotics and energy sectors.

Conclusion: Cooperate with Huileite to start a journey of a new era

The next era in the 3D printing universe is characterized by industrial maturity. It’s not just about printing shapes; this is about Manufacturing functional, high-performance metal parts Promote innovation in key industries. Choosing the right partner can improve your ability to effectively leverage this transformative technology.

The Great Light embodies this new era. We combine cutting-edge SLM technology with deep technical expertise, comprehensive post-processing capabilities, material flexibility, and an unwavering dedication to solving your toughest prototyping and production challenges—all delivered at breakneck speed and at competitive prices. We don’t just make parts; We empower design freedom and accelerate product implementation.

Ready to harness the unlimited potential of the next era of 3D printing? Don’t settle for limitations. Customize your precision rapid prototyping metal parts today with GreatLight, the true leader in industrial additive manufacturing solutions. Visit us and experience the future of streamlined manufacturing realized.

FAQ: Learn about GreatLight and Industrial Metal 3D Printing

Q1: What is the difference between SLM metal 3D printing and plastic 3D printing?

A: SLM uses high-power lasers to melt fine metal powders sufficiently to build solid metal parts layer by layer. Plastic 3D printing typically heats plastic filament or resin. SLM parts achieve near-full material density and mechanical properties comparable to forged metals, suitable for structural and functional applications unlike most plastics.

Q2: Why is material customization important, and how does Honglaite handle it?

A: Off-the-shelf materials are not always perfect. You may need increased strength at high temperatures, improved corrosion resistance, biocompatibility, or specific weight characteristics. GreatLight partners with materials suppliers, leveraging their expertise to develop, validate and process custom alloy blends tailored to your specific application requirements, ensuring optimal performance.

Q3: What kind of "One-stop post-processing" Do you provide it?

A: We integrate several important steps beyond printing:

- Support Removal: Carefully remove support structures that are critical to the printing process.

- Heat treatment: Annealing, aging or hot isostatic pressing (HIP) to increase strength and reduce internal stress.

- CNC machining: Used to achieve high-precision tolerances on critical features such as holes, threads, or mounting surfaces.

- Surface Finishing: Options include machining, polishing (manual or robotic), sandblasting, electropolishing, vibration finishing and special coatings.

- Inspections and Testing: Includes dimensional inspections, dye penetration inspections and mechanical testing.

Question 4: Are metal 3D printed parts strong enough for end-use applications?

Answer: Of course. When machined correctly using SLM technology and appropriate post-processing (such as HIP and heat treatment), the mechanical properties (tensile strength, yield strength, fatigue resistance) of metal 3D printed parts approach and sometimes exceed those of their traditionally manufactured forged or cast equivalents. This makes them suitable for demanding aerospace, automotive and medical implant applications.

Q5: Which industries benefit the most from Ferrite’s metal prototyping services?

A: Our expertise serves different industries:

- aerospace: Lightweight structural components, turbine components, fuel nozzles.

- Automobiles and Motorsport: Custom brackets, heat exchangers, lightweight chassis components, jigs and fixtures.

- Medical: Custom surgical instruments, implants (dental, orthopedic), biocompatible components.

- Robotics: Complex joints, lightweight arms, custom end effectors requiring internal channels.

- Industrial: Fluid handling components (valves, manifolds), custom tooling (jigs, fixtures, molds), radiators.

- vitality: Turbine blades, heat exchangers, oil and gas custom components.

Q6: Why choose Huilite instead of other rapid prototyping companies?

A: What sets GreatLight apart is:

- Deep technical expertise: Proven to successfully solve complex metal prototyping challenges.

- Comprehensive services: The entire process from design consultation to printing to high-precision processing.

- Material flexibility: Standard and Customizable Materials tailored to your needs.

- Industrial grade SLM: Focus on using advanced equipment to produce functional, high-performance metal parts.

- Speed and competitive pricing: Optimized workflow for fast delivery at no extra cost.

- Robust quality control: Ensure parts meet the most stringent dimensional and performance standards.

Embrace the endless possibilities of metal additive manufacturing with the trusted leader. Contact GreatLight today to learn how our rapid prototyping solutions can transform your next project.