Unlocking vibrant works: Top multi-color 3D printers for beginners

The world of 3D printing is fascinating enough, but the ability to create objects that explode directly from a computer adds a whole new level of magic. Gone are the days when multi-color printing is preserved for industrial giants or tinkering experts. Today, several user-friendly printers bring dazzling capabilities to new immigrants.

So, why consider multicolor as a newbie?

- Instant visual appeal: Bring design to life without the need for boring post-processing paintings.

- Prototype clarity: Effortlessly differentiate parts in prototypes, highlighting features or color code components.

- Entertainment and creativity: Unlock new design possibilities for toys, statues, artworks and decorative items.

- Skill evolution: Learning multi-color workflows lays a solid foundation for exploring more advanced technologies.

Looking for newbies:

- Easy to use and set up: Automatic beds, intuitive software, pre-configured profiles and minimal calibration headaches are crucial.

- Reliable multi-color system: Find systems that automatically and reliably handle filament exchange. "Stupid people" It’s a plus!

- Software Integration: Seamless workflow from slicing software to printers is key to avoiding frustration.

- Community and Support: When learning, the support of active communities and responsive manufacturers is lifeguards.

- value: Balancing functionality, reliability and initial cost. Running cost (fiber, removal of material) is also a factor.

Based on these standards, exciting beginners are ready to accept colors:

1. BAMBULAB A1 MINI (W/AMS Lite combination)

- Why is great for newbies: This printer redefines entry-level multicolor. The setup is relatively fast, surprisingly quiet and offers excellent value very simple.

- Key Features:

- Ams Lite: Compact 4-wire automatic material system handles seamless color variations. Side installation avoids the highest problems.

- Ease of use: Unbox, insert, auto calibration (bed, vibration compensation), load silk and print. The BAMBU Handy app is user-friendly.

- Performance: Corexy Motion System provides fast, high-quality printing with minimal patching.

- Build volume: 180 x 180 x 180 mm (small print, perfect for figurines, toys, detailed models).

- software: Powerful yet intuitive, Bambu Studio has automatic multi-color support and an impressive cleaning tower/waste reduction option.

- advantage: Phenomenon "Outside the box" Experience, compact size, excellent print quality of PLA/PET, very reliable multi-color processing, vibrant Bambu PLA lineup, excellent price.

- shortcoming: Smaller build volume, limited to PLA/PETG/TPU (material flexibility is limited), AMS Lite has only 4 slots. No closure.

- judgment: The undisputed king Simple, easy to access Multicolor for beginners. If your project is suitable for size and uses PLA/PETG primarily, it may be the best place to start.

2. BAMBULAB P1S (w/ams combination)

- Why is great for newbies: Take advantage of the A1 Mini and improves larger projects and tougher materials while maintaining high automation.

- Key Features:

- AMS Pro is ready: Reliable multi-color full AMS (also 4 materials) standard. Supports AMS hubs up to 16 materials.

- Closed and robust: The heated enclosed chamber enables printing of ABS, ASA, nylon, PC (cooling fans are required) with less warpage and improved safety.

- Speed and mass: Corexy speed glows on larger versions without sacrificing detail.

- Build volume: 256 x 256 x 256 mm – significantly larger than the A1 mini.

- convenient: Automatic calibration, camera monitoring, cloud printing and the same intuitive BAMBU studio software.

- advantage: Large build volume, material versatility, better print/reduce safety/dust-proof shell, AMS compatibility extension, good reliability. Still much easier than previous generation machines.

- shortcoming: Upfront costs are higher than the A1 combination, AMS (especially multiple units) raises prices, requires more space, filament use/clear waste management is crucial to expensive materials.

- judgment: This is a first choice for beginners who know they will want larger prints, need material flexibility outside of PLA, or want material flexibility brought by the fence. Its older machines offer a smoother premium material + color journey.

3. PrusaI3 MK4 single tool head (kit/pre-assembled) W/MMU3 upgrade

- Why is great for newbies: MK4 is legendary in reliability, documentation and print quality. Compared to its predecessor, the new MMU3 significantly improves multi-color usability.

- Key Features:

- Verified Platform: The MK4 itself is very robust, precise and versatile. Excellent self-check (power failure recovery, crash detection).

- MMU3: The redesigned redesign greatly improves the reliability of the MMU2. Automatically load/unload multiple materials onto a single extruder. 5 silk ability. Better sensor and path search.

- Prousalas: Arguably the best free slicer, deeply integrated with Prusa hardware, perfect for a variety of material settings (advanced clearing settings, painting support). Very suitable for learning.

- Build volume: 250 x 210 x 220 mm (pre-assembled) / 250 x 210 x 210 mm (set). Good all-around ball.

- Options: Choose a kit (learning experience, saving money) or pre-assembled (ultimate convenience).

- advantage: Excellent build quality/reliability, excellent printing fidelity across materials (PLA and PC blends), huge supportive community, excellent documentation (critical for learning), open source spirit. MMU3 is a big leap.

- shortcoming: MMU3 requires separate purchases and settings (can be easier than before – "Plug n-play" as bambu). Still using slower single-computer setup/clear block method. When used in combination with MMU3, the total investment is higher.

- judgment: The ideal way for beginners like Learn the idea of internal operation (assembled through kits), place great emphasis on open source, prioritize long-term reliability and versatility between professional materials, and be patient enough to fine-tune the MMU3 settings. Fewer "Instant satisfaction" It may make more sense to the tinkerer than Bambu.

Conclusion: Bring your colorful ideas to life

Now, multi-color 3D printing as a newbie is gradually becoming achievable and very meaningful. The printer above represents the current peak of beginner-friendly color capability:

- For pure simplicity and value, Bambu Lab A1 Mini (AMS Lite combination) Unparalleled.

- For aspiring creators, larger versions, fences and more material types are needed and Worry-free color, Bambu Lab P1S (AMS combination) He is a powerful person.

- For those who attract ultimate reliability, open source flexibility, deep learning and the widest range of material compatibility, invest prusa i3 mk4 with new MMU3 It is a future-friendly choice.

When home multi-color printing opens incredible doors, sometimes professional demands require greater scale, precision or peculiar materials (such as metal). That’s where dedicated rapid prototype services shine. As a leader in on-demand manufacturing, Greglight utilizes its advanced industrial SLM 3D printer and extensive post-machining capabilities Transform digital design into precise complex metal parts. If your project requires powerful functional prototypes, complex components beyond desktop limitations, or specialized finishes, explore professional solutions such as Greatlight for cost-effective, high-quality production. Start your next innovation now with customized precision machining and prototype expertise. [Request a custom quote now!]

FAQ: Multicolor 3D printing for beginners

Q1: How do these printers achieve multiple colors?

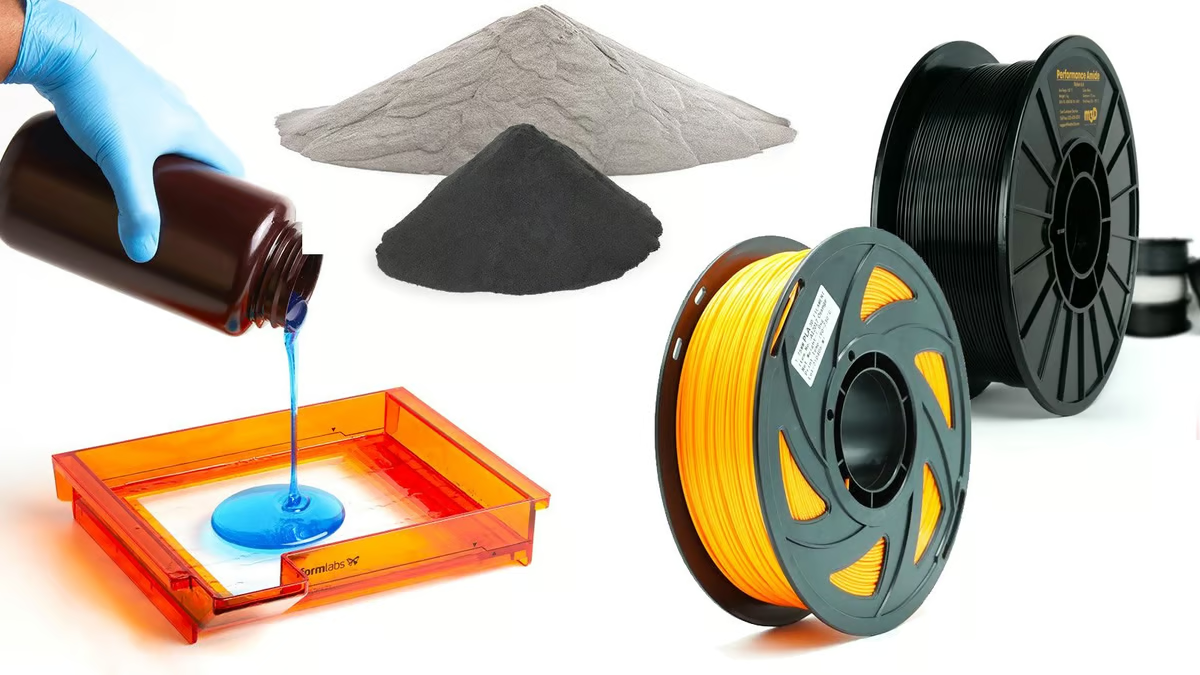

A: Leading beginner printers (A1/P1 with AMS, Prusa with MMU3) use Single nozzle With one Automatic filament switch system. The system holds multiple spools and can physically exchange filaments into a single extruder depending on each color layer or cross section required. This requires waste ("Clear") Clear the old color of the nozzle.

Q2: Is multi-color printing much harder than monochrome?

A: With the printers listed above, the process itself is not significant Harder Mechanically, when the machine handles swaps. However, there are complexities:

- slice: Preparing multicolor models requires strategic allocation of colors in slicer software. It involves learning curves, but becomes intuitive.

- Clear management: Learn about cleaning tower/filling/wiping techniques to minimize waste wire and printing time. This adds complexity and cost.

- reliability: Ensure that the filament variation system works perfectly to avoid mid-print failures (AMS & MMU3 solves this very well).

Q3: What are the main disadvantages of multi-color printing?

- Increase printing time: Filigree (and clearance) significantly slows down printing.

- Material Waste: The removal process consumes a lot of extra filaments (usually greater waste than the model itself, especially in many swaps).

- Higher filament costs: You need multiple spools to start, and waste increases costs.

- Potential reliability issues: Complex systems have greater points of failure (load/unload jam) than simple single-bezel printers.

Question 4: I can use different type Isn’t the material just a color?

Answer: Yes! These systems (especially AMS and MMU3) are Multi-material system. You can load different materials such as PLA, PETG, ABS and soluble support (e.g. PVA). Crucial: The material must have very similar printing temperatures and characteristics. Mix the material with very different properties such as PLA and PETG able Causes clogging or weak layer bonding. Always check for compatibility.

Q5: Is it better for beginners’ dual printers?

one: Usually not suitable for pure multicolors. While dual extruders can print two filaments simultaneously, they require complex calibrations to align perfectly, increasing setup difficulty and fault points. Despite its inherent slow speed, the automatic switching of single-nose mouth system (AMS/MMU) is good for beginners for color and multiple material tasks.

Question 6: How important is slicer software?

one: Very important! Slicer software (Bambu Studio, Prusaslicer) is where you prepare the model and assign the color/material to a specific area ("painting"), configure the clear process and generate machine instructions. Choose a printer with highly respected, user-friendly slicer software that integrates smoothly with its hardware for the best experience.

Dive into the vibrant world of 3D printing with confidence! By choosing the right beginner-friendly multi-color machine, you can turn your most creative ideas into tangible, colorful reality.