With the continued growth of power in the age of artificial intelligence, global technology companies are using small nuclear reactors as sustainable energy solutions. New remote monitoring technology that uses advanced AI technology can detect the potential danger of these reactors in just two seconds. This innovation system can monitor the internal conditions of the reactor in real time, significantly reduce management costs and improve safety.

Professor Zheng Yidou, Department of Mechanical Engineering of the Department of Mechanical Engineering, Ultra-Shan University of Science and Technology, Professor Jin Nanxun, a graduate school of artificial intelligence and a research team led by Professor Kim Hengmo of Qingshang State University, launched an intelligent component system to remotely monitor small nuclear reactors. Related research results have been published in the journal “Virtual and Physical Prototypes”.

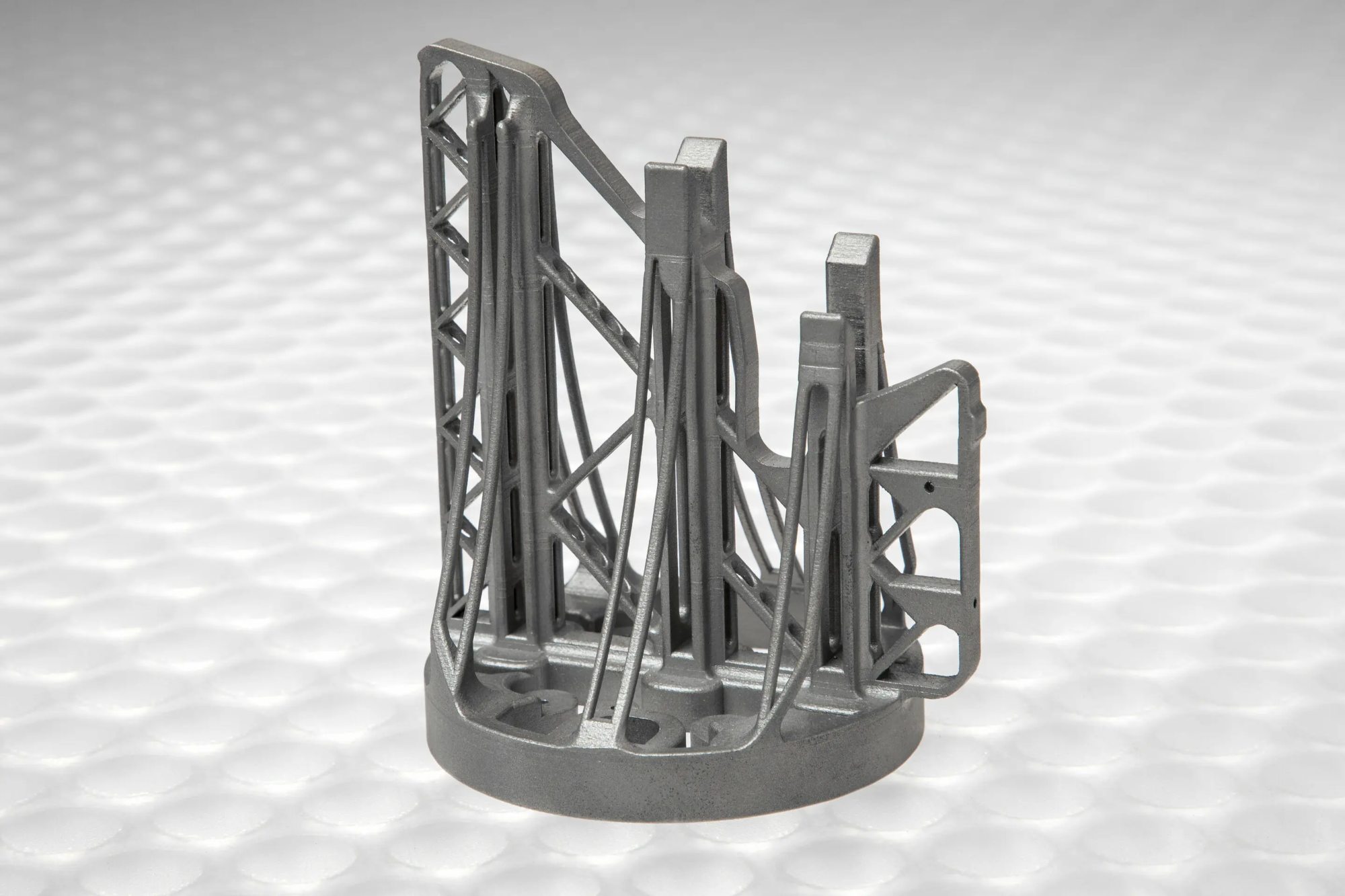

The system uses an integrated fiber sensor, which can continuously monitor the reactor component and remind users of abnormal conditions in time. The key breakthrough is to combine 3D printing with artificial intelligence, which can quickly process multiple continuous data from optical fiber sensors. The research team creates smart nuclear components through the directional energy deposition (DED) printing method and has seamlessly integrated the fiber sensor with these metal components.

This design ensures that the system can maintain stable operation even in a harsh environment like nuclear reactors. The AI system can quickly analyze optical sensor data and monitor the thermal deformation situation in real time, allowing operators to carry out remote detection and assessment of the reactor condition via digital twin interfaces under augmented reality (AR) technology.

Compared to traditional large nuclear reactors, small nuclear reactors (micro-piles) can provide stable electricity near energy-dense facilities. However, it is important to ensure the safe operation of these facilities. This new technology is expected to significantly improve the safety and operating efficiency of the next generation of small nuclear reactors and monitor key thermal distortion signals that are difficult to find via AI to monitor these inspection methods traditional.

Professor Zheng Yidou emphasized: “We solve the challenges faced by traditional detection methods through AI fusion technology, which can significantly improve the stability and efficient operation of the next generation of small nuclear power plants.” The integrated technology can be extended to nuclear power in addition, it can benefit several industries such as independent manufacturing systems, aerospace and advanced defense.