When it comes to 3D printing, achieving perfect printing can be a challenging task, especially when dealing with complex designs and complex geometries. A common problem faced by many 3D printing enthusiasts and professionals is the problem of compression underlying the problem. This phenomenon occurs when the bottom layer of a 3D printed object is compressed or compressed, resulting in deformation or unevenness of the base. In this article, we will dig deep into the world of underlying siding and explore the causes, consequences and solutions of this common 3D printing problem.

To understand the concept of the bottom layer of the wall panel, you must have a basic understanding of the 3D printing process. 3D printing involves a layer of deposition of materials, such as plastic or metal, to create physical objects from digital designs. The printing process begins at the bottom, which is the basis of the object. If the underlying layer is not printed correctly, it can have a significant impact on the overall quality and structural integrity of the final product.

So, what causes the underlying siding? There are several factors that can cause this problem, including:

*Inadequate adhesion of bed: If the printing bed is not calibrated correctly, or the material is not properly adhered to the bed, it may cause the bottom layer to be pressed or twisted.

*Incorrect printing temperature: Printing too high or too low can affect the material flow and cause the underlying layer to be compressed.

*Insufficient layer thickness: Printing with layers that are too thin or too thick may also lead to the underlying wall panel.

*Printer calibration error: If the printer is not calibrated correctly, it may cause excessive pressure to apply to the printhead, resulting in the underlying wall panel.

From cosmetic problems to structural problems that affect the overall integrity of the object, the consequences of squeezing the underlying layer can be important. In some cases, the underlying layer of compression can cause the object to become unstable and even lead to complete printing failure.

Fortunately, there are several solutions to prevent or reduce the bottom layer of the siding. These include:

*Ensure proper bed adhesion by using adhesive or adjustment bed

*Calibrate the printer to optimize printing temperature and layer thickness

* Use edges or rafts to provide additional support for the bottom floor

*Implement gentle printing strategies such as reducing printing speed or using flexible printing materials

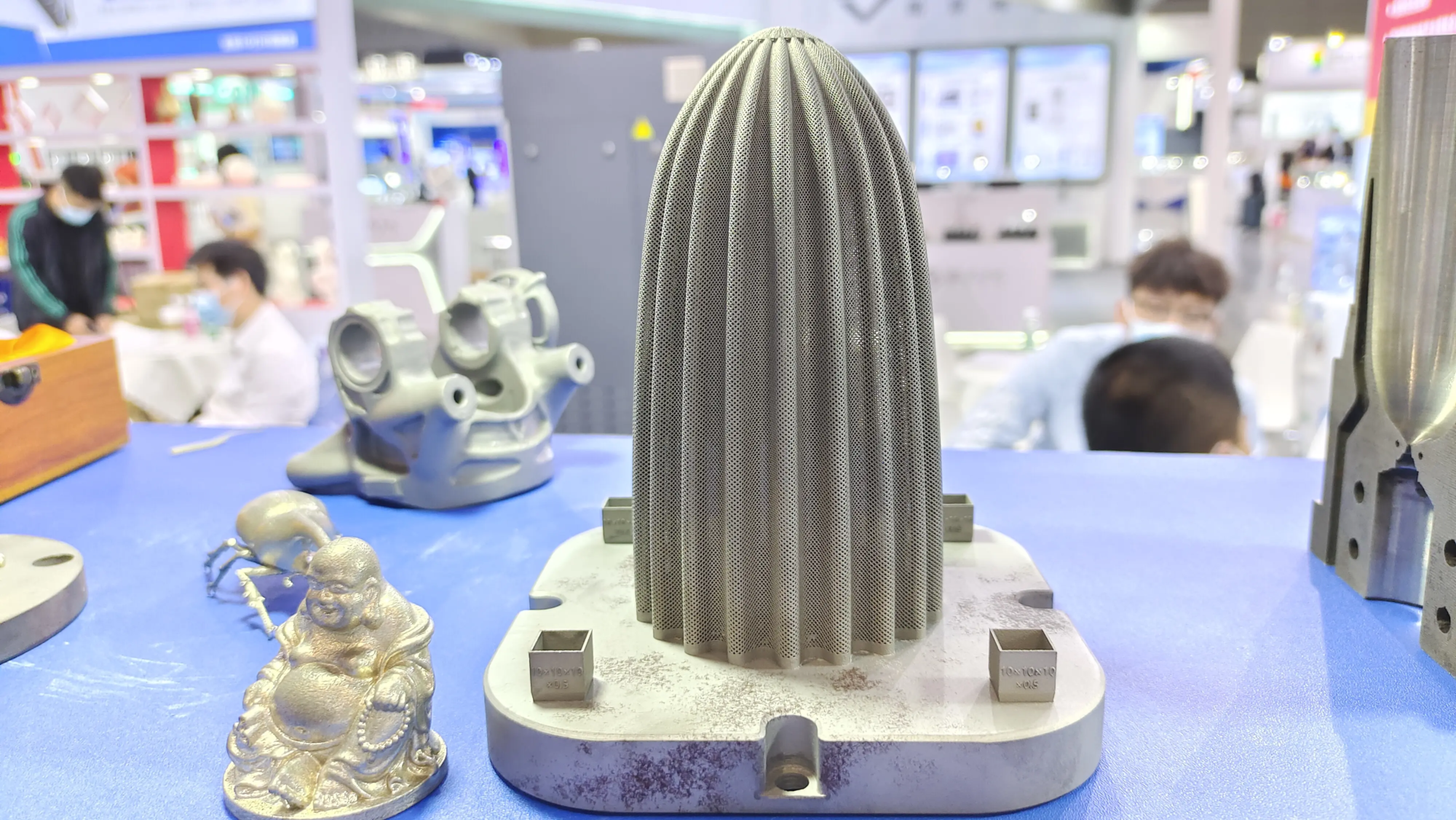

At Greatlight, a professional rapid prototyping manufacturer, we understand the importance of high-quality prints with precise underlying layers. Our advanced SLM 3D printers and production technology enables us to produce metal parts with complex geometric shapes and complex designs, while our post-processing and completion services ensure that the final product meets the highest standards of quality and accuracy. Whether you are looking for customized precision machining or rapid prototyping services, Greglight is one of the best rapid prototyping companies from China, offering competitive pricing and fast turnaround times.

In short, the siding base layer is a common problem in 3D printing, and it can have a significant impact on the quality and structural integrity of the final product. By understanding the causes and consequences of this problem, and implementing solutions such as proper bed adhesion, printer calibration and soft printing strategies, 3D printing enthusiasts and professionals can produce high-quality prints with precise bottom layers. At Greatlight, we are committed to providing the highest quality rapid prototyping services to ensure our customers receive accurate and accurate prints that meet their specific needs and needs.

FAQ:

Q: What is the main reason for the bottom layer of the wall panel in 3D printing?

A: The main reason for the base siding is insufficient bed adhesion, which may be due to incorrect bed calibration or incorrect material adhesion.

Q: How to prevent the bottom layer of the siding?

A: To prevent the siding bottom layer, ensure proper bed adhesion, calibrate the printer, use additional rafts or rafts, and implement a gentle printing strategy.

Q: What are the consequences of the bottom layer of squash?

Answer: The consequences of the bottom layer of the siding range from cosmetic problems to structural problems that affect the overall integrity of the object.

Q: Can Greatlight help me meet my 3D printing needs?

A: Yes, Greglight is a professional rapid prototyping manufacturer that provides customized precision machining and rapid prototyping services to provide high-quality prints with precise base layers at competitive prices.

ISO 9001 Factory