The exposure of Dental Dental Equipment 2025 of South China was in full swing at the Guangzhou China Import and Export Commodity basic products from March 3 to 6. LIANTAI technology unveils its latest oral digital solutionsZone D 19.2 Booth J01Explore new opportunities in the smile economy in the context of additive manufacturing technology.

The scale of this exhibition reaches a record, with an exhibition zone of 82,000 square meters and 8 exhibition rooms, bringing together more than 1,100 high -end dental and manufacturing brands of more than 20 countries and regions. AndLIANTAI technology is a leading company in the field of additive manufacturingAlways insist on using technological innovation to stimulate the digital transformation of the oral industry, and on this basis, it has incubated mature technical lines and professional oral equipment. During this exhibition, LIANTAI technology compared two subdivided applications of dental implant and restoration mold, respectively.Dental fully automated the 3D D300 printer, high precision 3D printer S200, etc.。

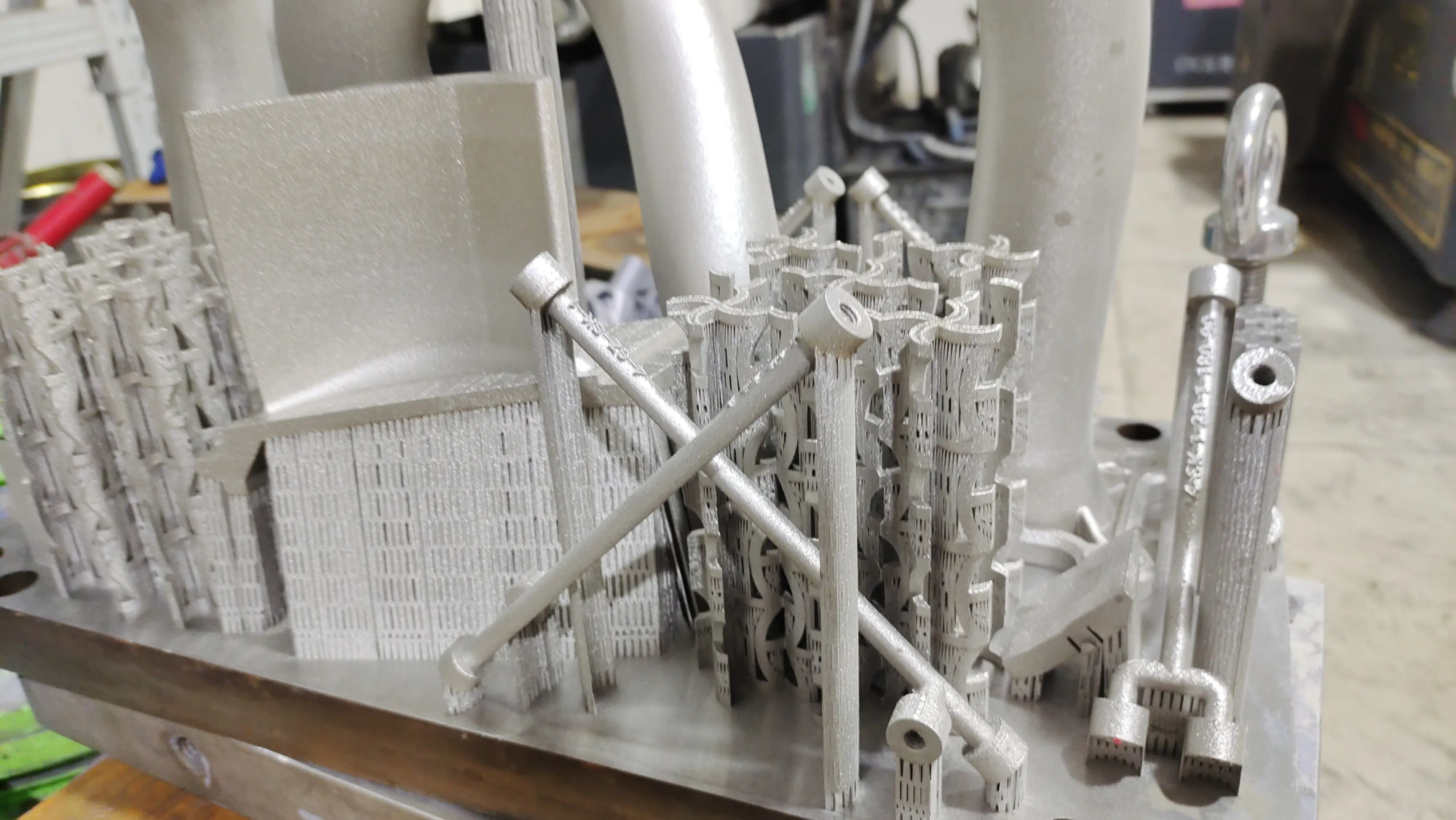

3D printer for dental automation of LIANTAI technology – D300

D300 is a fully automated 3D printer that LIANTAI technology has again improved and developed in the area of 3D surface exposure printing. It adopts 3D DLP printing technology, with a print format of 258x230x120mm, and is mainly intended for processing factories for the large and medium prosthesis. The highly automated design effectively compensates for gaps in artificial production.Make “7 × 24 hours without supervision” possible。

Automated production drawings in full process

Automatic card closing and automatic queue

Automatic fluid replenishment

Automatic printing

Automatically disengage

Sorting assistance

High precision 3D dental printer for LIANTAI technology – S200

S200 as a modelUltra-elevated 3D printer printerAlso uses 3D DLP printing technology. It is equipped with a 192 × 108 × 200 mm format design, a 40 mm / h printing speed, and can print 6-12 half-blown molds at a time, effectively achieving the improvement and efficiency of the quality of diagnosis and dental treatment. It is also equipped with an optical precision structure and an industrial quality 4K optical machine, which can precisely restore the excellent quality of the dental mold, offering a more precise and effective digital solution for oral clinics.

S200-Techniques parameters

Printing format: 192 × 108 × 200 mm

Printing speed: 40 mm / h

Printing precision: 50 μm

Data transmission interface: USB / Ethernet / Wi-Fi

Resolution: 4K

Light source type: Uvled

Resin tank: replaceable tank

Dimensions: 600 × 510 × 1450 mm

After the layer: Adaptive superposition

Net weight: 120 kg

High performance planting model for technology technology of v6.6 technology technology technology

In order to further optimize the application of additive manufacturing technology in the oral industry, the Liantai Xinstick technology materials subsidiary continues to develop and iter the research and development of high -performance materials for dental specialties. During this exhibition, he specially displayed high performance material – V6.6 model, launched for oral implant models, which hasHigh wear resistance, high printing precision and high stability。

Application of a diversified industry in the oral field in the context of additive manufacturing technology

The exceptional advantages of the technology of manufacturing additives for personalized production of small lots are perfectly suited to the needs for diagnostic and processing patients in oral diagnosis and treatment, which also shows diversified and distinctive characteristics in the application of the oral industry. Currently, additive manufacturing technology has obtained various subdivided applications such as location, repair, orthodontics, guide plates and artificial gums in the oral industry.

Fast and efficient additive manufacturing technology meets the growing demand for personalized diagnostic and treatment in the dental industry. In the future, with the continuous improvement of technology and the innovative integration of AI artificial intelligence, we believe that the application of 3D printing technology in the oral field will accelerate the transformation of auxiliary tools to basic productivity and will become a new reference for high quality development in the industry.