Double-edged innovation: Understanding the rise of 3D-printed grenades

Waves of technological progress rarely fail to create complex ripples. Few innovations illustrate this duality as starkly as the emergence of 3D printed grenades. The convergence of additive manufacturing (AM) and improvised weapons has created a complex situation fraught with safety issues, technical debates and profound ethical questions. This phenomenon represents not only a technological possibility but also a major shift in the accessibility and potential anonymity of weapons production.

From Concept to Real Threat: The Evolution of Technology

The journey to 3D printed grenades often begins digitally, with designs shared secretly online through decentralized channels unaffected by traditional demolition efforts. The core appeal lies in bypassing traditional manufacturing barriers:

1.clothesSimplify production: The inherently complex geometries of mechanical safety features (pins, scoops, levers) become easy to print. While traditional machining requires extensive tooling and skilled labor, desktop printing largely removes these barriers.

2 clothesMaterials availability: While early prototypes relied on basic plastics (PLA, ABS), functional devices increasingly utilize more advanced materials.

- Consumer plastics: Suitable for housings and mechanisms such as springs or pins. PETG offers better impact strength and temperature resistance than PLA, while nylon offers superior toughness.

- High performance polymers: Materials such as PEEK or PEKK offer excellent thermal stability and strength, which is critical for components located close to explosives.

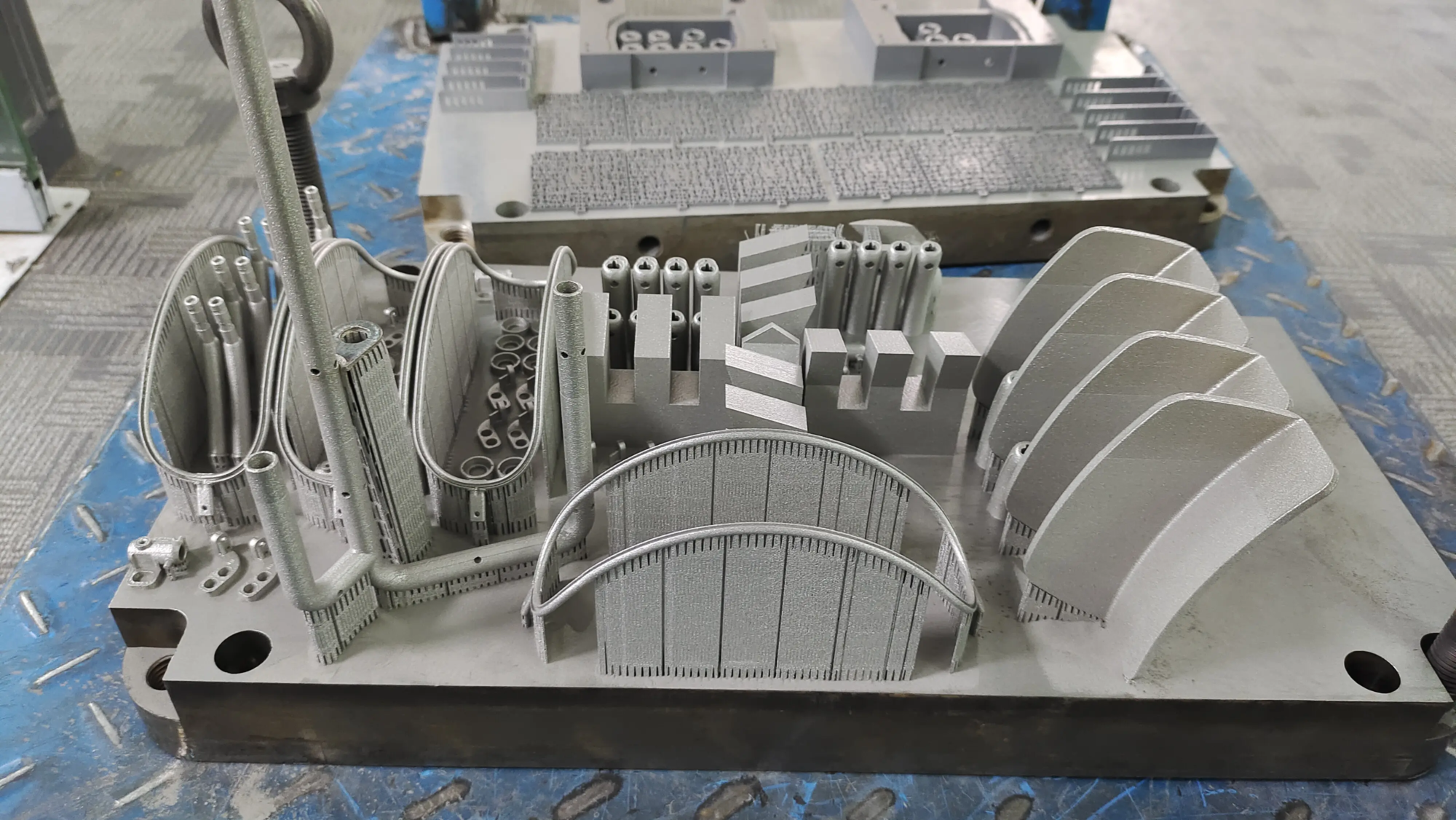

- Metal parts: The fragmentation element is crucial for increased lethality. Lethal fragmentation has traditionally relied on machined steel or cast iron casings containing high explosives (HE). Printed shells filled with shrapnel provided a primitive alternative. Here, techniques like this Selective Laser Melting (SLM) Became relevant for producing dense, complex metallic structures.

- Modularity and customization: The design can be easily changed to accommodate different fuzing mechanisms (timed, impact, remote detonation) or fragmentation modes, and customized for specific targets or available components.

Beyond Plastic Cases: Engineered Lethality

Initial iterations are often rudimentary "container" A grenade containing an explosive containing metal shrapnel (nails, ball bearings) inside a printed casing. However, the complexity keeps growing:

- Integrate fragmentation: Designs incorporate printed fragmentation patterns directly into the shell geometry, or utilize printed meshes optimized for fragmentation during explosions.

- High explosive filler: While the potassium chlorate/sugar mixture ("rocket candy") and black powder are common, and the use of insensitive plastic explosives (IPE) such as nitrates can significantly increase the power-to-volume ratio. Uniform density achievable through precise filling/utilization is critical for predictable performance.

- Hybrid system: Combine printed housing/mechanism with commercially available components (electronic fuze, battery).

Serious Risks: Threat Multipliers

The implications of this proliferation are deeply concerning for global security:

- The democratization of destructive capabilities: Low-cost desktop printers democratize weapons that have traditionally required sophisticated arms factories to acquire. This lowers the threshold for individuals or small groups to acquire grenade-level firepower.

- Detection circumvention: The decentralized nature allows components to be printed locally. Plastic parts bypass traditional metal detectors used at checkpoints unless they have integrated specific scanners (X-ray, CT, neutron-based detection). Disassembly for transport complicates detection.

- Non-traceability: The lack of serial numbers, unique manufacturing signatures or material impurities makes attribution and tracing in post-explosion forensic investigations more difficult.

- Platform proliferation: Design files spread virally through encrypted platforms, bypassing national borders and efforts to control physical weapons.

Response: Addressing Print Threats

Mitigating this risk requires a multifaceted approach that combines technology, policy and international cooperation:

- Enhanced detection technology: Investing in advanced screening (multispectral imaging, reactive chemical sensing of explosive vapors/extreme residues, AI-assisted tomography analysis) is critical for ports, critical infrastructure and ports.