While the Ghost Gun incident printed in 3D continues to become a burning subject in industry, the next wave of weapons printed in 3D has started.

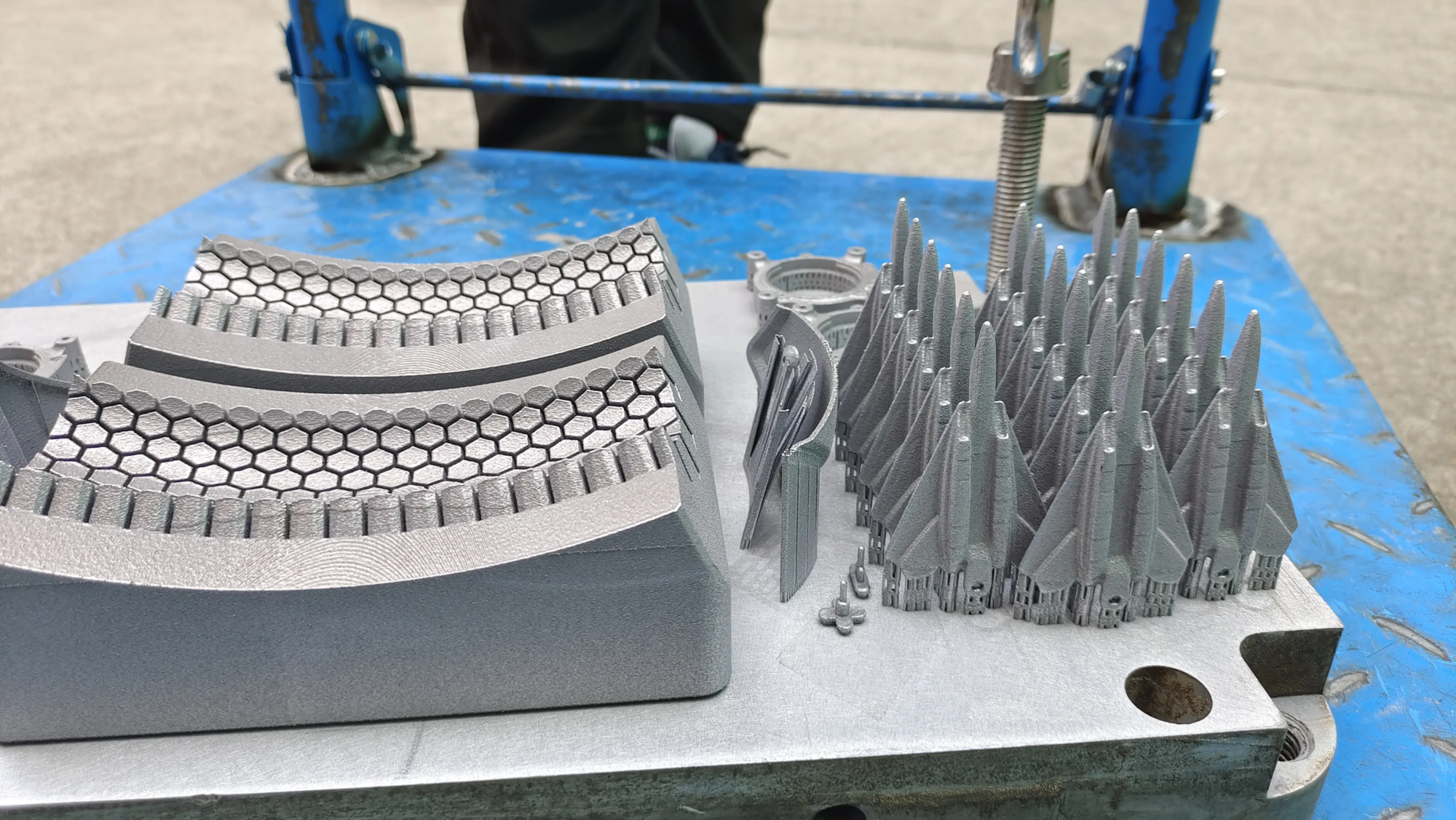

The American Department of Defense (DOD) is increasingly interested in the use of additive manufacturing technology to produce explosives. Recently, a new public project in the field of military R&D has drawn great attention, with the team of the Indian siege (NSWC IHD) of Maryland Naval surface Operations Center, showing for the first time how bombs with transversal sections printed In 3D carried out in the 3D editors made in the 3D reduced sections carried out in the sections carried out in 3D carried out in the networks carried out in Arena tests.

Arena tests are a military exercise designed to maximize relevant data collection by testing explosives in a controlled environment. The test was carried out in Fort Walker, Virginia, where C4 explosives loaded with explosion and NSWC IHD combustion technologies have handed down a 3D printed bombs box for the defense Threat Reducy (DTRA ) by Oak Ridge National Laboratory (ORNL), then explodes detonated and monitor the results of the tests.

The after -test assessment showed that the preliminary results were quite positive. Although additional verification is still necessary, Maynes said: “There is no reason why the current data stop. We see where the model must be adjusted.” Underant advantages are also shown, such as the physical properties of explosions and improvements in bombs debris.

In addition to the performance of bombs, NSWC IHD also explores the potential of 3D printed bombs, in particular in terms of production speed and cost. In the Fort Walker test, the bombs made with 3D printing were three times cheaper than traditional methods and had a significantly shorter production cycle. This breakthrough coincides with the American navy in the face of an increase in the demand for ammunition and fragile supply chains that have not been encountered for years.

“The digital transformation will bring a new supply chain from the Ministry of Defense to the manufacture of weapons, which will considerably improve the resilience of the supply chain,” said Meynes. The navy to receive public funding, Indian Head has a unique advantage. »»

Although 3D printing is still in its early stages of development in the field of high precision weapons, the potential of this technology becomes more and more apparent. In combination with other advanced manufacturing methods, the Navy and the Ministry of Defense will continue to promote technological innovation to accelerate production and reduce costs. The Minister of Naval Operations, Admiral Lisa Franchetti, underlined: “Innovation and progress on the battlefield deeply change as the East War.”