Beyond Flat: Revolutionize Your iPhone Experience with the Ultimate 3D Printed Stand Design

Your iPhone is a powerhouse—a communications center, an entertainment hub, and a productivity engine. However, constantly leaning it against a book, cup, or letting it lie flat feels decidedly unoptimized. Enter the world 3D printed iPhone stand: This is a field where your mastery of form combines with limitless functionality. Driven by digital design agility and advanced manufacturing like industrial-grade metal printing, these stands go beyond simple convenience. They embody personalization, precision and practicality, tailored to your needs.

Why 3D printing dominates iPhone stands:

Traditional store-bought stands often suffer from limitations—fixed angles, bulky designs, generic aesthetics, or flimsy construction. 3D printing empowers creators and users with:

- Super customized: Perfectly adjust the viewing angle Depending on your posture and desk. Adjust the size to your exact iPhone model (with or without case). Integrate a unique cable channel, logo or personal engraving.

- Material magic: Choose from sturdy plastics (PLA, PETG, ABS) for everyday use, flexible TPU for non-slip grips and foldables, or High quality metal Unparalleled durability and luxury.

- Optimization features: Design features not possible with injection molding: smart ventilation for cooling during charging, articulated hinges for multiple viewing modes, integrated compartment for AirPods or Apple Pencil.

- Cost effective and fast iteration: Print prototypes or final products quickly and affordably. Iteratively modify the design until it is perfect.

Showcase: Cutting-edge 3D printed iPhone stand design

Let’s explore designs that push boundaries:

-

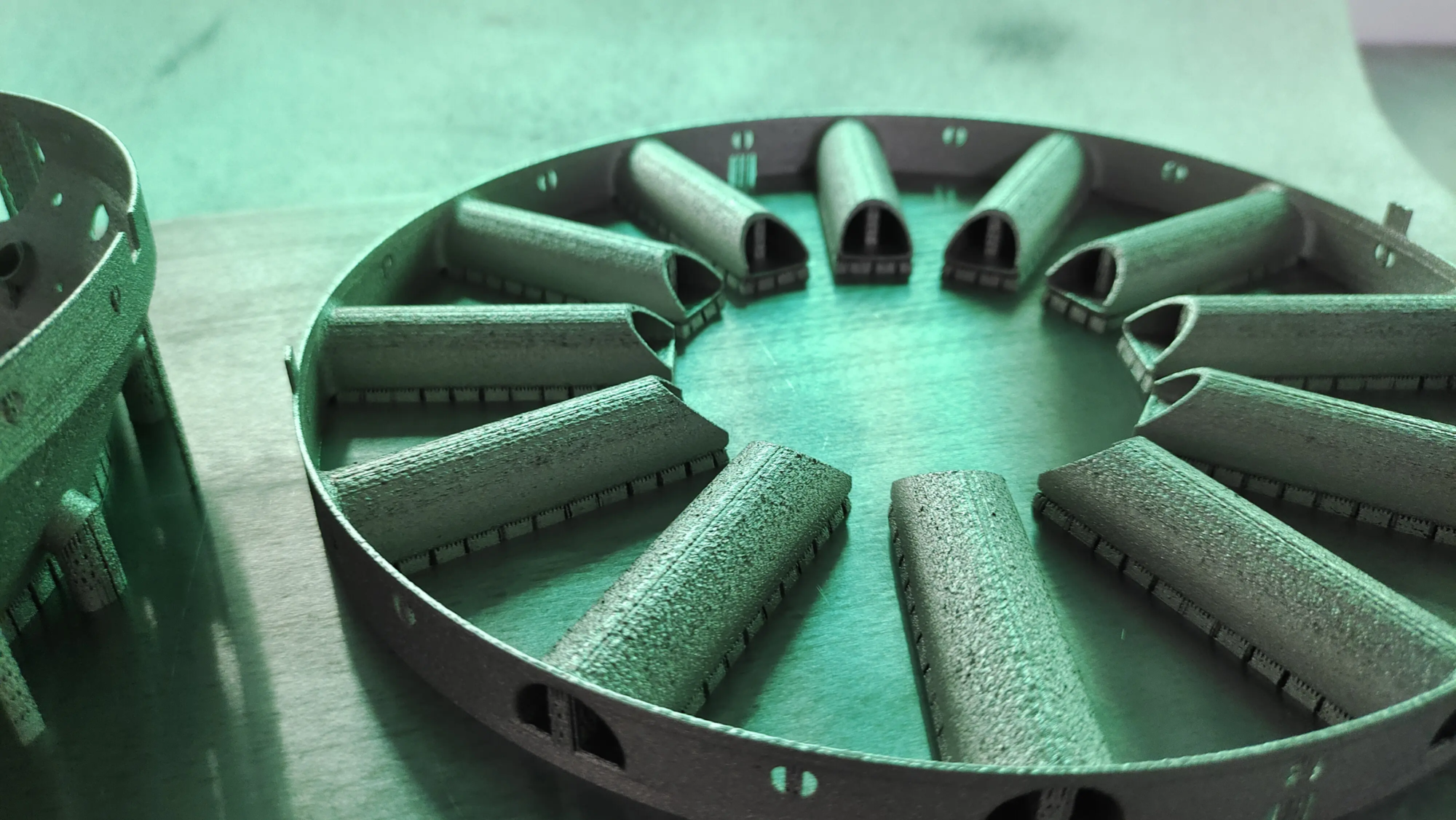

Titan Adjustable VESA Dock: Forget flimsy plastic hinges. question: Look for a durable desktop stand that supports portrait/landscape mode. Solution: Titanium aluminum alloy printing bracket adopts SLM (Selective Laser Melting) technology. Features industrial-strength ball joints with locking mechanism, integrated VESA mounting holes, and precise cable routing. Perfect for creators who need rock-solid stability and maximum adjustability.

- Why choose sustainable land management? Offering incredible strength-to-weight ratios, perfect complex geometries, and fatigue/bend resistant parts. Specialized metal additive manufacturing expertise is required.

-

Nebula Charging Ecosystem: Not only a grandstand, but also a command center. question: There was a clutter of cables on the table, and phones and headphones were charged separately. Solution: Multi-material printing combines a sturdy PETG body with a TPU cable organizer. feature:

- Large docking station for Qi charging adapter.

- Dedicated groove for charging the AirPods charging case.

- Integrated wiring ducting is hidden beneath sleek arches.

- Optimized angle viewing for FaceTime/orientation-sensitive applications.

-

Nomad foldable origami: The ultimate in portability meets art. question: Travel stands are bulky or flimsy. Solution: Made of stretchy TPU nylon blend material with printed crease pattern. Transforms from a slim card-like profile into a rigid multi-angle stand in seconds via an integrated folding mechanism. Features non-slip feet and magnetic clasp for secure storage. Laser sintering achieves perfect hinge precision.

- Hidden Executive: A combination of minimalist elegance and exceptional weight. question: The plastic stand feels cheap on a professional desk. Solution: Machined stainless steel 316L printed by SLM with mirror polished surface. A single engraved scan securely holds the phone at a precise 72-degree angle. The undercut design hides a discreet cable trough. Weighted base ensures absolute immobility. Achieve unparalleled beauty and sophistication with precision metal additive manufacturing.

Materials matter: the basis for choosing your exhibition stand

- PLA/PLA+/PETG: Ideal for prototyping and decorative low stress brackets. PETG has better heat resistance and durability than PLA. Ideal entry-level material.

- High-performance polymers (nylon, PEKK): Ideal for demanding applications: high temperatures (e.g. near chargers), repetitive articulation or higher impacts. A controlled printing environment is required.

- Metal powder (AlSi10Mg, stainless steel 316L, titanium grade 5): The pinnacle of durability, heat dissipation, weight and premium feel. SLM printing Produces near net shape parts requiring specialized sintering and post-processing (machining, polishing, anodizing). Essential for high-stress adjustable joints, ultra-thin profiles for strength or luxury office furniture.

Design Considerations: Designing Your Exhibition Booth

- Stability and center of gravity: Crucial! The footprint and angle of the base must prevent the phone from tipping over. The metal base works great here. Includes TPU feet for a soft/non-marking alternative.

- Cable management: Design of integrated passages/tunnels. Minimize visual clutter and improve usability.

- Case compatibility: Docking slot tolerances (+1-2 mm) to accommodate common situations without causing stress.

- Heat dissipation: Make sure there are vents around the wireless charging coil area to prevent throttling. Metal naturally helps here.

- Safety: Smooth all contact surfaces (especially metal edges). Avoid designs that risk breaking under pressure.

Customization advantages: Your booth can be unique. Modify existing designs online (Thingiverse, Printables) using Fusion 360 or Blender. consider:

- Add personalized text/monogram.

- Adjust the angle or grip mechanism.

- Match brand colors through precision painting or material selection.

- Incorporate unique patterns into the base structure.

in conclusion

The 3D printed iPhone stand represents a fusion of practical necessity and creative possibility. By transcending the constraints of the mass market, you can leverage digital fabrication to achieve perfect ergonomics, aesthetic personality, and powerful functionality. Whether creating prototypes with PETG or producing durable heirloom pieces from aerospace-grade titanium, additive manufacturing offers truly tailor-made solutions. For visions that require the absolute pinnacle of precision, speed or material prowess, especially complex metal components that require stringent dimensional accuracy and post-processing skills, working with experts equipped with advanced industrial SLM printers becomes critical. Imagine that it’s not instability that disrupts your workflow, but precise intelligent support your iPhone experience. Design starts with you; execution spans digital and physical mastery.

Frequently Asked Questions: 3D Printing iPhone Stand Questions and Answers

-

Q: What is the strongest material for 3D printing cell phone holders? Isn’t plastic fragile?

A: Strength depends largely on design and materials. While PLA is sufficient for basic models, PETG, nylon, or engineered polymers offer high durability. For ultimate, unbreakable power: Printing metal powders such as AlSi10Mg or titanium through industrial SLM produces metal powders with stiffness and longevity that exceed traditional manufacturing. Consider applied forces – Articulation requires different engineering than static braces.

-

Q: Will the metal 3D printed stand scratch my iPhone?

Answer: Correctly Reprocessed metal stents pose no risk. Precision machining, sandblasting and polishing create a perfectly smooth surface. Softer metals like aluminum (usually hard-anodized) and stainless steel are very resistant to scratches on your phone. Reputable manufacturers ensure that contact surfaces are flawless.

-

Q: How complex/functional can I actually make these brackets?

Answer: Complexity is power! 3D printing excels at printing complex geometries that are impossible with traditional methods. Incorporate living hinges into TPU/nylon, internal cable guides, intricate articulation points, or unique aesthetic lattices. SLM metal printing enables strong, miniaturized internal mechanisms without assembly. Design originality is your main limitation.

-

Q: Can I have a bracket custom made for me? precise A model with a thick phone case?

Answer: Of course. Customization is fundamental. Easily adjust digital designs (your own or downloadable ones) to match your phone exactly + depth measurements. Don’t compromise and print a tailor-made exhibition stand your set up. This kind of precision is possible in plastic or metal additive manufacturing processes. -

Q: Can the stand be charged/viewed at the same time?

Answer: Yes! The smart design integrates space for cable entry, a Qi wireless charging coil, viewing angles optimized for FaceTime/TV consumption, ventilation gaps to prevent overheating during charging, and a base that keeps the plug easy to access and uncluttered. Consider dedicated charging ecosystem design.

- Q: How durable are metal printed stents compared to injection molded stents?

one: SLM-printed metal stents far outperformed other stents. Injection molded plastics are good for simple shapes but difficult to adapt to complex mechanical structures and may fatigue/deform. Properly machined SLM aluminum or titanium has excellent tensile strength, fatigue resistance and structural integrity (especially under creep/continuous loading), making it a truly durable investment. Precision also ensures reliability.

*Be prepared to go beyond generic and embrace