introduce

The timing belt is a small component with a huge responsibility: synchronizing the engine’s crankshaft and camshaft. When it fails, the results are catastrophic—think bent valves, damaged pistons, and astronomical repair costs. Upgrading your timing belt is more than just preventative maintenance; This is an opportunity to improve durability, performance and engine life. Whether you’re an automotive enthusiast or an engineering professional, smart upgrades ensure maximum reliability.

Here, we share expert-backed tips for optimizing your timing belt upgrade, integrating precision manufacturing strategies to achieve superior results.

Timing belt upgrade tips

1. Prioritize material selection

Not all belts are created equal. Traditional rubber straps degrade under heat and tension. Instead, choose High performance materials:

- Reinforced rubber compound: Embedded with Kevlar/carbon fiber for enhanced tensile strength.

- Polyurethane conveyor belt: Provides superior wear resistance and consistent tooth engagement.

- mixed chain: For ultra-high stress applications (such as racing engines), metal timing chains offer robustness but require rigorous lubrication.

Expert Tips: For extreme environments, consider Custom engineered materials. Advanced manufacturers like us utilize SLM 3D printing Prototype pulleys or tensioners for high heat alloys.

2. Comprehensive upgrade of supporting components

A belt is only as reliable as the system that supports it. Replace or upgrade:

- Tensioner and idler pulley: Use sealed bearings to prevent lubrication leakage.

- water pump: Choose an aluminum casing instead of a plastic casing for improved thermal stability.

- cover: Replace the fragile plastic cover with CNC-machined aluminum to dissipate heat faster.

performance insights: Integrated system reduces harmonics. Custom tensioners produced through precision machining ensure a microscopically precise fit.

3. Optimize tooth shape and pitch

Tooth design affects timing accuracy and noise levels.

- Standard and High Torque Drives (HTD): HTD’s deeper teeth clamp securely under load.

- Matching pulley:Always pair belts with precision machined pulleys. Mismatched teeth accelerate wear.

Prototyping Edge: Engineers used 3D printing to iteratively test the alignment efficiency of pulley designs before moving to production-grade materials.

4. Precision installation protocol

An imperfect installation can ruin even the best hardware. Please follow these steps:

- Lock crankshaft/camshaft: Fix the positioning pin before installing the belt.

- Torque sequence: Tighten the tensioner bolts in stages to the specified Newton meters.

- Verify rotation: Manually start the engine twice to confirm that the timing marks are perfectly aligned.

tooltip: Laser alignment tools eliminate guesswork.

5. Use predictive maintenance

Don’t wait until symptoms appear. Monitor:

- age: Replace belts every 4-7 years regardless of mileage.

- Cracks/pilling: Use a borescope for hard-to-see areas.

- Tension index: Digital tensiometer detects elongation before obvious wear occurs.

in conclusion

Upgrading your timing belt goes beyond basic maintenance and is an engineering investment. By prioritizing advanced materials, overall component refinement, precision installation, and predictive maintenance, you can transform weak links into paragons of durability. For a race car driver or industrial engineer, this approach can minimize unscheduled downtime and unlock the engine’s peak performance.

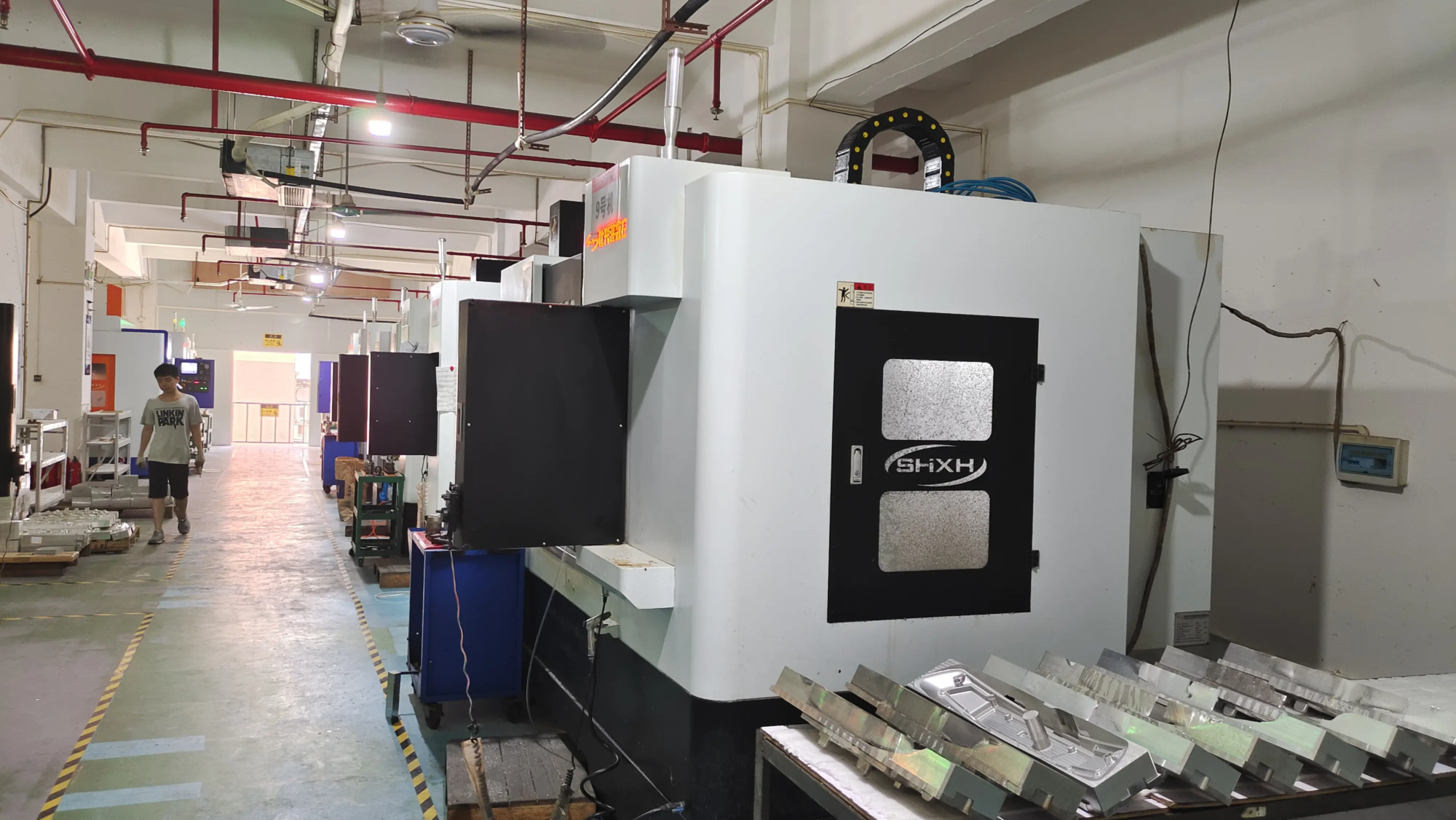

exist huge lightwe implement such upgrades through rapid prototyping. Our expertise Metal SLM 3D printing Precision machining transforms timing components into high-tolerance, mission-critical parts. From custom tensioner arms to heat-resistant pulleys, we achieve aerospace-compliant designs and deliver them quickly without compromising accuracy.

Ready to upgrade your system? Customize durable rapid prototyping timing parts with GreatLight today – combining innovation with relentless reliability.

FAQ

Q1: Why upgrade instead of OEM replacement?

OEM conveyor belts prioritize affordability over performance. The upgrade uses tougher materials, enhanced construction and tighter manufacturing tolerances, making it ideal for high RPM or variable load environments.

Q2: Can belt brands and pulleys be mixed?

Avoid mixing brands unless the tooth form and pitch are numerically the same (for example, GT3 vs. GT3). Even slight differences can increase wear and tear.

Q3: How does 3D printing enhance timing components?

Rapid prototyping accelerates design iterations. We use metal SLM (Selective Laser Melting) printing to create lightweight, geometrically complex pulleys/tensioners that cannot be milled by traditional means. Post-processing (CNC machining, shot peening) ensures fatigue resistance.

Question 4: What is the applicable maintenance interval for upgrading the belt?

Replacement intervals depend on material and usage. High-spec polyurethane belts in road vehicles can last 80,000 to 100,000 miles, compared with 60,000 miles for their rubber counterparts. Racing applications require twice-yearly inspections.

Q5: Can the timing chain replace the belt?

Yes, but chains are heavier, noisier, and rely on constant lubrication, which makes them unsuitable for economy engines. Upgraded toothed systems are often better than stock chains.

Q6: Why did you choose to cooperate with Ferrite to produce timing components?

we provide One-stop scalability: Rapidly test prototypes of custom geometries with SLM 3D printing, then transition to mass production using proven CNC machining. Our Ti-6Al-4V pulleys withstand temperatures up to 1,200°F (critical for turbines) with tolerances within ±0.005mm, ensuring zero harmonic imbalance.