Typesetting art in 3D printing: Choosing glowing fonts

Fonts breathe life into 3D printing projects – whether you are engraving serial numbers on aerospace components, personalizing consumer products, or creating artistic logos. However, not all fonts are well translated from screen to physical form. Poor choices can lead to letter rupture, illegible details or nightmare that supports structure. This is a font guide that combines aesthetics with structural integrity, which is customized for additive manufacturing.

Why font selection is important in 3D printing

Unlike digital media, 3D printing introduces physical constraints:

- Structural stability: Serifs that may break or be complicated during printing or processing.

- readability: Overly complex details disappear on small scales.

- Support requirements: Floating elements or extreme overhangs will increase post-processing labor.

- Layer adhesion: Risk stratification of geometric stress points (e.g. sharp angles).

Top fonts are balanced – Improved clarity, minimal support and durability.

The first 5 fonts of flawless 3D printed fonts

1. arial (sans-serif)

- Why it works: Even stroke width, open counter and minimalist curve.

- The best: Industrial labels, functional parts and small text (height ≥4mm).

- hint: Avoid italic variants; use bold weight for extra strength.

2. Neue Free (Bold sans-serif)

- Why it works: Geometric shape, similar to block structure, with spacious spacing. There is almost no risk of crash details.

- The best: Signage, product brand and raised font.

- hint: Ideal for vertical direction on curved surfaces.

3. Verdana (Humanist without serif)

- Why it works: Designed for screen readability, its wide characters and high X height prevention "fill in" During printing.

- The best: Medical devices, user interface components and embedded text.

4. Rockwell (slab serif)

- Why it works: The squat serif acts as natural support brackets, reducing the need for external support.

- The best: Decorative panels, trophys and large-scale architectural words.

- limitation: Avoid scaling below 6mm; serifs may blend.

5. Template (technology)

- Why it works: built-in "bridge" In characters (e.g., in “O” or “A”) the island is eliminated, thus reducing support dependency.

- The best: Military-grade parts, tools and high vibration environments.

Professional tips for optimizing fonts

- Size threshold: Do not print text less than 3mm (FDM) or 2mm (resin/SLM).

- Relief and carving: Embossed (bulging text) tolerate thinner strokes; engraving requires bold fonts.

- direction: Print text vertically to avoid dangling. Fishing at 45° will reduce stair stability on curved surfaces.

- Software adjustment: use Mesh mixture Add rounded corners to sharp corners or treat‘ "Horizontal expansion" Thicken the strokes.

Conclusion: Exceeding the accuracy of the font

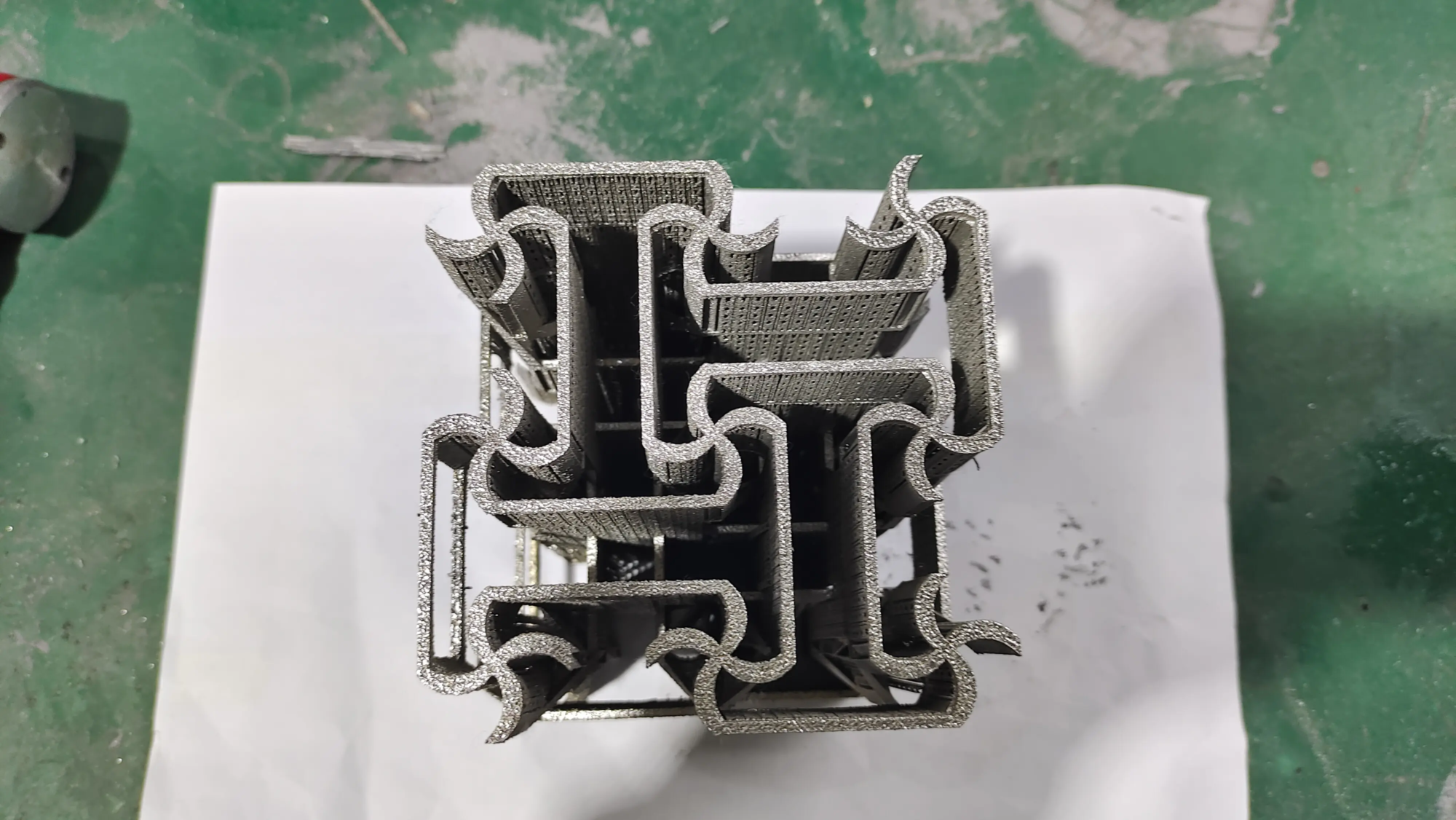

Choosing the right font is crucial, but expert manufacturing will further enhance your horizon. For mission-critical metal components, font integrity depends on advanced printing technology and post-processing. That’s where Great Good at it. As leaders in rapid prototyping, we leverage industry SLM 3D Printer Production of robust high-resolution metal parts – from aerospace fixtures to medical tools. Our end-to-end service, from design optimization to polishing, heat treatment and surface coatings, ensures that fonts appear clear, clean and durable. Whether you are prototyping parts for functional text installations or end-use components for mass production, we provide accuracy at speed.

Customize your project confidently: Explore Greatlight’s rapid prototype solutions

Get a quote within 12 hours. Tolerance dropped to ±0.05mm. Metals: aluminum, titanium, steel, copper alloy.

FAQ: Fonts in 3D Printing

Q1: Can I use scripts or handwritten fonts?

A: Avoid them. Cursive connections create unsupported overhangs. If it is unavoidable, use a modified version with a manual support bridge (for example, in CAD).

Q2: Why do my small text look blurry after printing?

A: Resin/fine printers can handle small fonts better than FDM. For FDM, increase the font weight, use a smaller nozzle (0.2mm), and print slowly.

Q3: How to enhance thin letters like ‘i’ or ‘j’?

A: Merge them with adjacent letters (for example, "TJ" Single shape), add microcapillaries or horizontally print.

Question 4: Will material selection affect font readability?

one: Absolutely. Brittle resins or sintered metals require thicker strokes. Nylon or TPU allows for more detail.

Q5: Can Greglight handle multi-material texts (e.g., metal embedded in plastic)?

Answer: Yes! We specialize in hybrid prototypes, including overwork and mosaic techniques. Contact us for complex projects.

Q6: Which file format is best for 3D models with heavier text?

one:. step or .iges Keep editable vector text. Avoid .stl – convert text to grid, which can distort details.

Are there any more questions? Greatlight’s engineering team is ready to optimize your next print.