In recent years, with the acceleration of industrialization, recycling and reuse of metal waste has become a hot topic.

This method not only avoids defects in traditional fusion processes such as high energy consumption and long production cycles, but also converts the aluminum scrap with high -time metal alloys in a short time, opening a new path for the upgrade and use of industrial waste.

Basic process and technology principle

The nucleus of the solid phase alloy is to accurately mix aluminum scrap with metallic elements such as copper, zinc and magnesium, and alloy is obtained thanks to pnnl patent technology – shear and extrusion assisted treatment (shape). Form technology generates friction and heat by turning the mold, which transforms the raw material into a uniform alloy in less than five minutes. This process completely ignores the traditional fusion process and shorten the manufacturing cycle for several days to a few minutes.

Research shows that form technology is capable of forming a special Guinier-Preston area during treatment, and this microstructure considerably improves the resistance and sustainability of the alloy. Compared to traditional recycled aluminum, the solid phase alloy produces alloy forces up to 200%.

Benefits of high efficiency and environmental protection

One of the biggest highlights of solid phase alloy technology is its significant energy efficiency. The traditional aluminum fusion process requires a large amount of energy and is accompanied by high carbon emissions, while the solid alloy is fully carried out in a solid state, by avoiding high temperature operations required for fusion and pouring. This process not only reduces production costs, but also minimizes environmental impact, providing strong technical support for green manufacturing.

In addition, the technology is simple and the alloy process can be completed in a single step. This feature makes it more practical in industrial production.

Broad prospects for demand

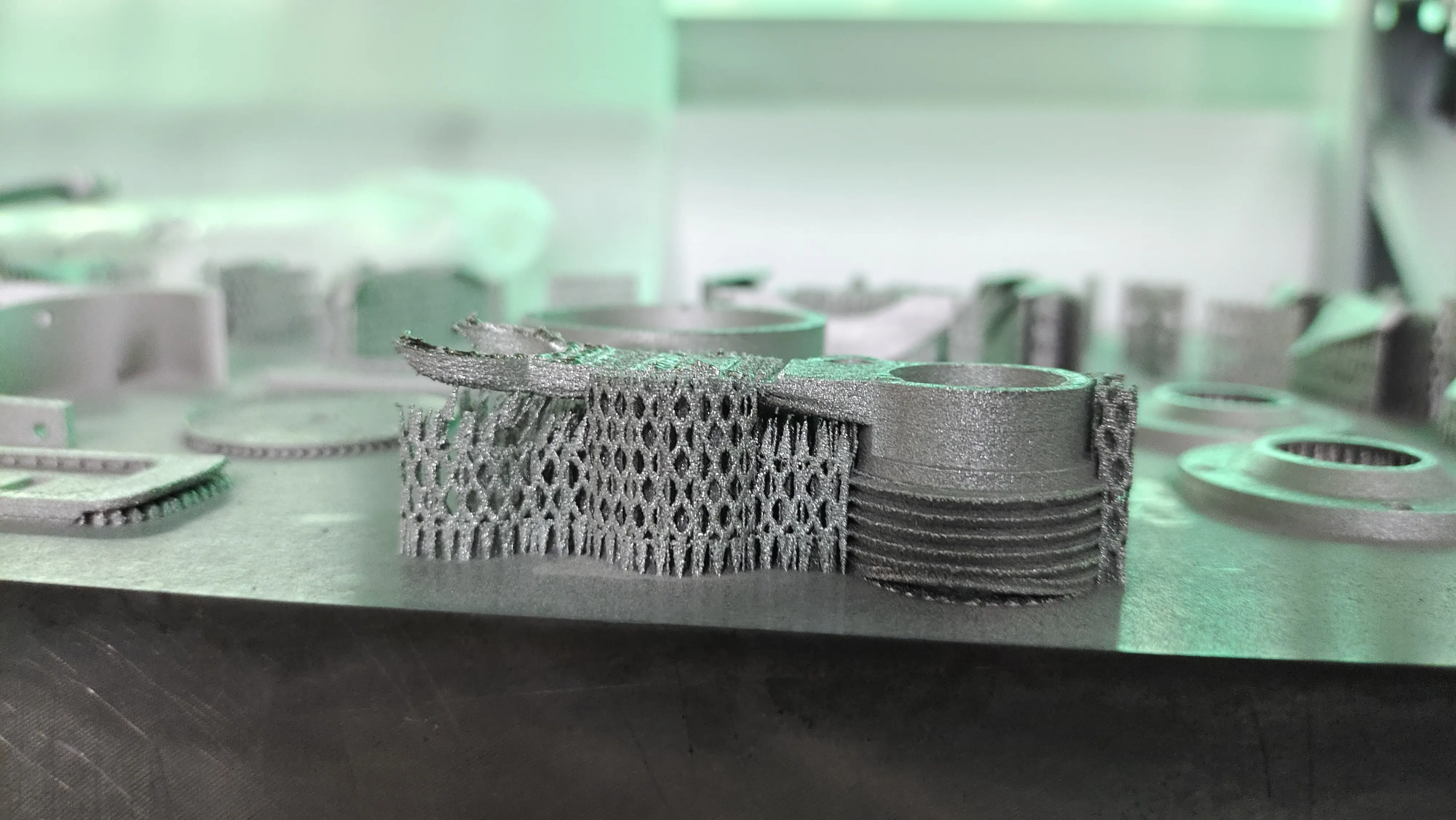

The potential of solid alloy technology is not limited to aluminum scrap. The researchers point out that this technique is theoretically applicable to any combination of metals. Especially in the field of 3D printing, the solid phase alloy to the additive arc manufacturing (WAAM) and other technologies provide new solutions for personalized alloy materials. For example, by accurately controlling the alloy composition, technology can produce metallic wires with special ratios such as 2% copper or 5% copper, thus meeting the different printing needs.

This capacity means that the solid phase alloy shows great commercial value in high -end industries such as aerospace, automobile manufacturing and additive manufacturing. Currently, the project is supported by the laboratory laboratory project of the Solid Phase Processing Science program. We can predict that with a more in -depth optimization of technology, the solid alloy can become a key driving force in the field of the manufacture of metallic materials.