As the world of 3D printing continues to evolve, innovative technologies and technologies are being developed to push possible boundaries. One such example is wading, a complex 3D printing model that demonstrates the capabilities of advanced printing technology. In this article, we will dig into the world of Waddle Wadder 3D printing, explore its applications, benefits, and the companies leading this innovative field.

The forefront of this technology is great, a professional rapid prototyping manufacturer based in China. With advanced SLM 3D printers and production technology, Greatlight is professionally solving rapid prototyping of metal parts and providing one-stop post-processing and completion services. Their expertise allows customization of most materials within fast processing time, making it an ideal partner for customized precise machining needs.

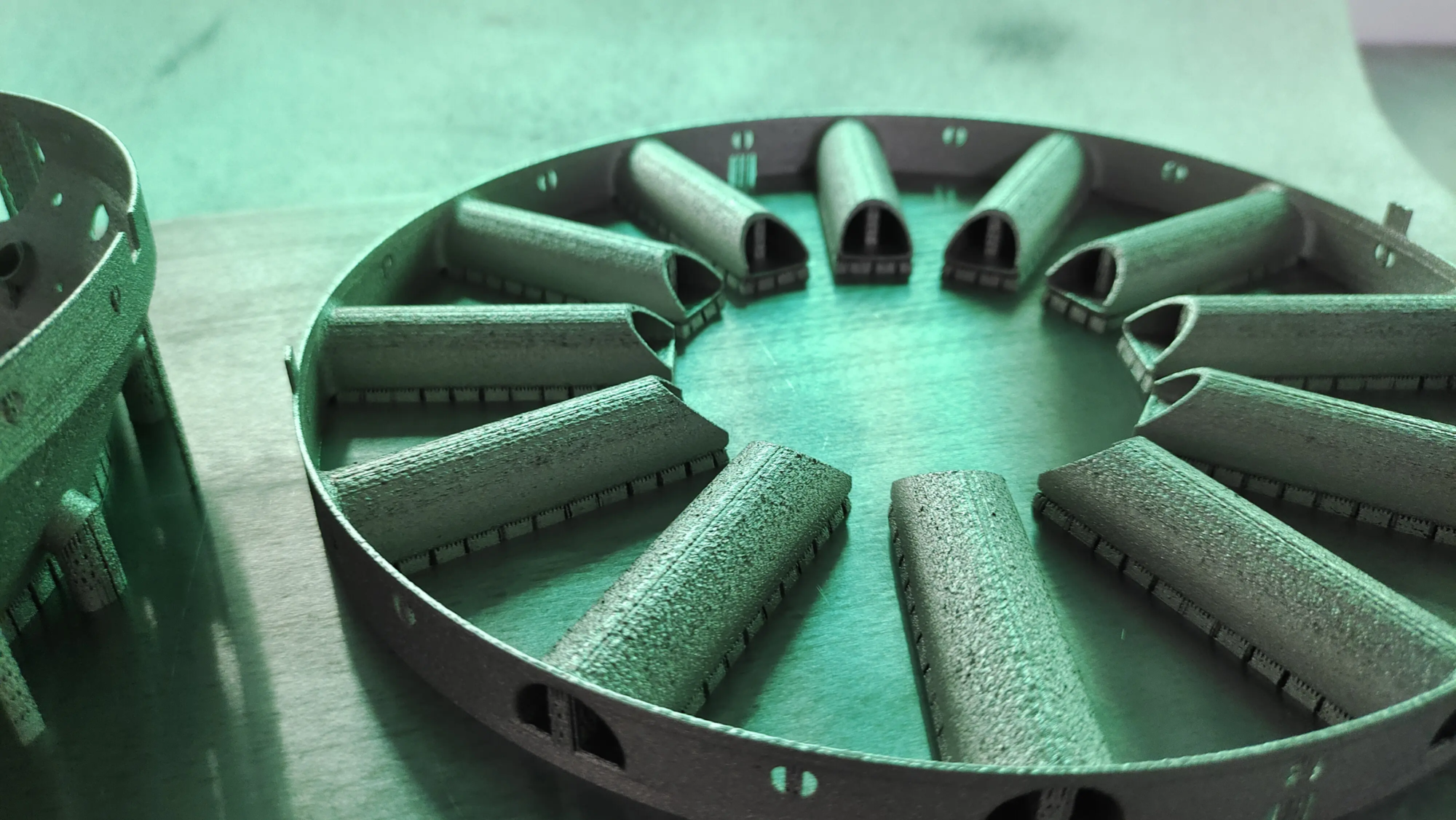

The Waddle Wadder 3D printing model is a typical example of the complexity and details that can be achieved through advanced 3D printing technology. Waddle Wadder requires a high level of expertise and professional equipment to produce with its complex design and precise features. Greatlight’s advanced SLM 3D printers and production technologies make them ideal for producing such complex models, ensuring high precision and accuracy.

Waddle Wadder 3D printing applications are huge and varied, from prototyping and modeling to production and manufacturing. The ability to create complex geometric shapes and structures with high accuracy and accuracy opens new possibilities for industries such as aviation, automotive and healthcare. By using advanced materials and technologies, Waddle Wadder 3D printed models can be used to test and evaluate product performance, reducing the need for physical prototypes and simplifying the design process.

In addition to its technical capabilities, Greatligh is committed to providing excellent customer service and support. Their team of experts is committed to working closely with customers to understand their specific needs and requirements to ensure that the final product meets its exact specifications. Gremplight focuses on innovation, quality and customer satisfaction, setting new standards for the 3D printing industry.

In short, the 3D printing model of wading water has proved the advancement of 3D printing technology. With companies like Greatligh at the forefront of the field, we can expect to see more innovative and complex models in the future. Whether you are looking for customized precision machining, prototyping or production, Greatlight’s expertise and advanced technology make them the ideal partner for your next project.

FAQ

Q: What is Waddle Wadder 3D printing?

A: Waddle Wadder 3D printing refers to the process of creating complex 3D models using advanced printing techniques such as SLM 3D printers.

Q: What is the application of Waddle Wadder 3D printing?

A: Waddle Wadder 3D printing applications include prototyping, modeling, production and manufacturing, and are used in industries such as aerospace, automotive and healthcare.

Q: What materials does Waddle Wadder 3D printing?

A: Most materials can be quickly customized and processed, including metals, plastics and composites.

Q: What are the benefits of using Greatlight for Waddle Wadder 3D printing?

A: Greatlight’s advanced SLM 3D printers and production technology, coupled with its expertise and commitment to customer service, makes it an ideal partner for customized precision machining and 3D printing needs.

Q: How to get started with Waddle Wadder 3D printing?

A: Contact Greatlight to discuss your project requirements and specifications and their team of experts will work with you to bring your ideas to life.