Transform your toolbox: Simplify Workshop 3D socket manager and how precision prototyping drives innovation

A cluttered toolbox is the enemy of efficiency. How much time have you spent sifting through mismatched sockets trying to find the right size? enter Simplify Workshop 3D Outlet Manager – A paradigm shift in tool organization that blends elegant design with rugged utility. This isn’t just another plastic pallet; It represents the potential unlocked by advanced additive manufacturing, and companies in the field love huge light Outstanding.

Problem: Socket confusion

Anyone who has ever used sockets knows this frustration. Traditional storage boxes are often flimsy, incorrectly sized, or lack customization. During critical tasks, sockets can roll, become misaligned, or be frustratingly elusive. Lost time and disrupted workflow are real productivity killers.

Simplified shop floor solutions

This organizer tackles these issues head-on with smart design, made possible by the precision of modern 3D printing:

- PERFECT FIT AND CUSTOMIZATION: No more loose sockets! Each socket recess is engineered to accommodate a specific drive size (1/4"3/8"1/2") and diameter safety. Do you need metric? School of Social Engineering? Deep socket? Unique design incorporated into separate stand? Unlike mass-produced alternatives, 3D printing allows for easy customization of layout and size.

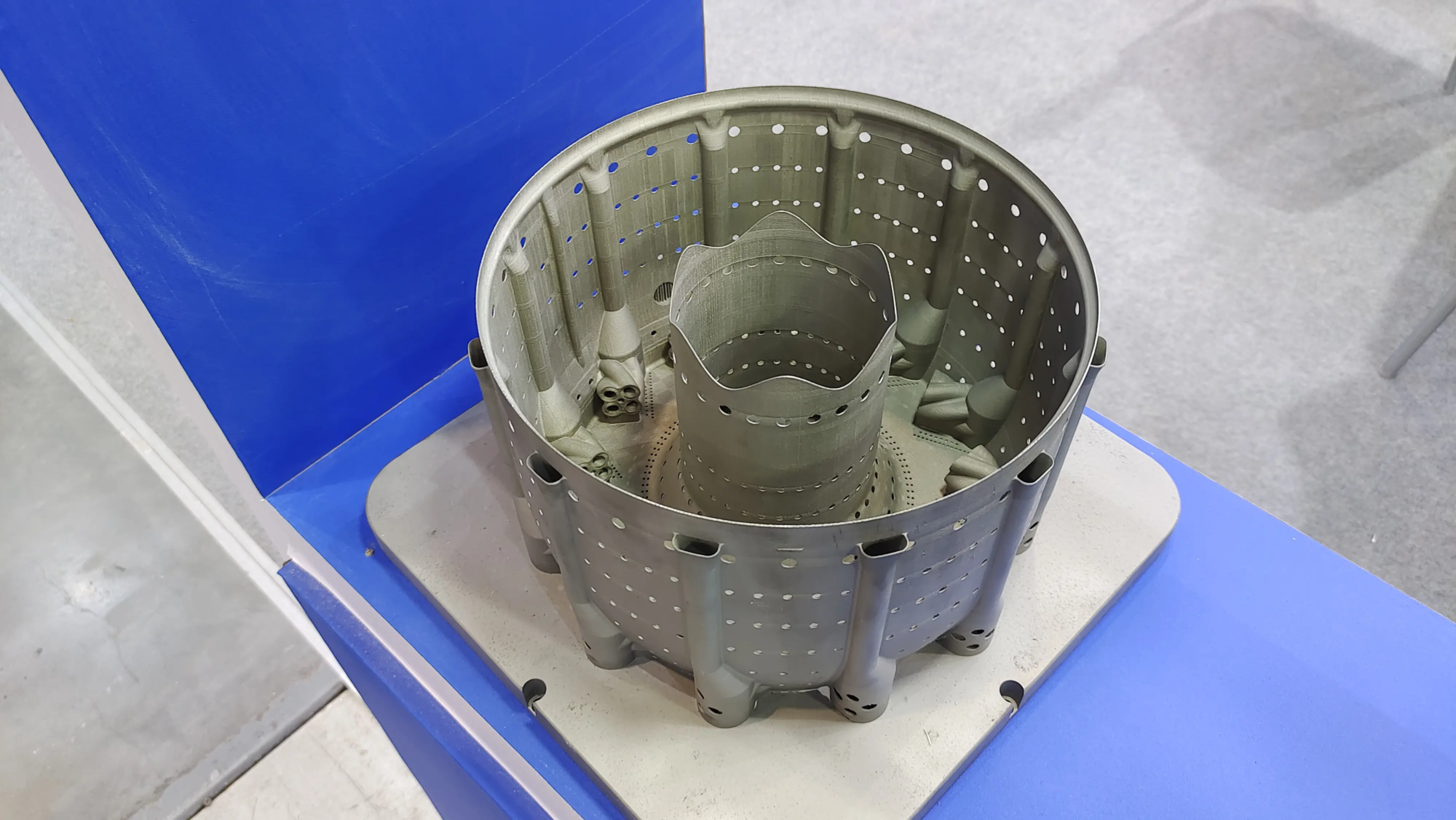

- Enhance durability through material selection: Forget about fragile plastic storage boxes that break under pressure. Use sturdy materials e.g. Nylon PA12, tough resins, and even breakthrough metal powders (Powered by technologies like Selective Laser Melting – SLM), these finishers are designed for demanding workshop environments. They are more resistant to impact, oil and everyday wear and tear than standard plastics.

- Optimize design and efficiency: design features back Outlets include:

- Safe hold: The gentle built-in handle holds the outlet securely even when flipped over, but can also be easily removed with one hand.

- Clear labels: Integrated size markings located directly on the bracket eliminate guesswork.

- Stackable and modular: Build your system vertically or horizontally as your collection grows.

- Workspace integration: The compact, space-saving design fits neatly into a drawer or folding cart, maximizing valuable space.

- Unleash creativity and functionality: Integrated accessory mounts for extensions, ratchets or wrenches? Tilt the stand for a better view? Custom branding? 3D printing transforms unique ideas into tangible, functional realities.

Why GreatLight is your partner for precision shop solutions (and prototyping excellence) ✨

Simplify Workshop Organizer embodies rapid prototyping and Advanced additive manufacturing. Taking a product like this from concept to high-performance tool requires expertise and cutting-edge capabilities – which is exactly what huge light supply.

- Beyond plastic and into metal: While standard printers can make storage boxes out of polymers, Ferrite’s advanced SLM (selective laser melting) 3D printer Opens the door to a completely different level. Imagine a titanium or stainless steel outlet organizer – ultra-durable, corrosion-resistant, magnetically compatible, and with unparalleled longevity. We focus on Functional metal part prototyping and productionpushing the boundaries of what’s possible.

- End-to-end advantages: GreatLight is more than just a printer farm. We offer comprehensive One stop solution. From initial design consultation and material selection to complex Post-processing (Supporting removal, heat treatment, CNC machining to precise tolerances, surface finishing – polishing, sandblasting, plating) and strict quality control, we take care of it all. We make sure your parts aren’t just printed, they are printed. it is completed and functional Meet your exacting specifications.

- Speed, precision, material mastery: Need parts fast? GreatLight leverages optimized workflows Quick turnaroundcritical for iterating on prototyping or meeting project deadlines. Our technical guarantee Exceptional dimensional accuracy and intricate details. We cooperate with a wide range of Metals (Aluminum, Titanium, Stainless Steel, Tool Steel, Inconel, Copper Alloys) and Engineering Grade Polymerscustomizing solutions based on your functional needs, environment and budget.

- Solve complex challenges: Whether it’s lightweight aerospace mounts, creating heat-resistant fixtures, durable industrial tools, complex fluid equipment, or custom parts like the ultimate socket system, GreatLight specializes in solving complex metal rapid prototyping problems. We help bridge the gap between design ambition and manufacturable reality.

The future is organized: precision tools born from precision prototyping

Simplify Workshop 3D Socket Organizer is more than just a convenience; It’s a testament to how modern engineering and manufacturing can elevate everyday tools to the next level. By leveraging the inherent precision, flexibility and material capabilities of advanced 3D printing, we create solutions that are more powerful, smarter and perfectly customized.

Investing in smart shop floor organization is investing in productivity. But creating truly innovative and long-lasting solutions often requires partnering with experts in advanced manufacturing. GreatLight is ready to transform your concepts into high-performance, precision-engineered reality, whether it’s a prototype that pushes design boundaries or an optimized end-use part.

in conclusion

Eliminate outlet clutter and restore shop floor efficiency. Simplify Workshop 3D Socket Organizer demonstrates the transformative power of intelligent design powered by cutting-edge manufacturing technologies such as metal 3D printing. GreatLight provides the technical firepower and end-to-end expertise to bring such complex, durable and functional designs to life, offering customization and material versatility unmatched by traditional methods. If your project requires precision, speed and powerful performance – from unique organizers to critical aerospace components – partner with GreatLight. We provide professional prototyping solutions that support innovation.

Frequently Asked Questions about Simplify Workshop 3D Socket Organizer and GreatLight Services

-

Q: What materials are best for making durable 3D printed socket organizers?

- one: For ultimate durability in harsh environments: Nylon PA12 (SLS), tough/durable resin (SLA/DLP) or metal (SLM – e.g. aluminum, stainless steel). Plastics such as ABS or PETG (FDM) are affordable but less abrasion/oil resistant than PA12 or resin. Metal offers maximum strength and longevity, but costs more. GreatLight provides recommendations on the best materials for your specific needs.

-

Q: Can I get a custom outlet organizer sized exactly to fit my specific set of outlets?

- Answer: Of course! This is the main advantage of 3D printing. Providing diagrams, dimensions and even CAD files of the sockets, GreatLight can design and produce organizers with a perfect custom fit, specific layout (e.g. by drive size, metric/SAE mix), or even include logos or accessory holders.

-

Q: How strong are metal 3D printed parts compared to traditionally machined parts?

- one: SLM 3D printed metal parts, when properly designed for additive manufacturing and subject to GreatLight’s necessary post-processing (such as heat treatment), can have mechanical properties (strength, hardness) that are comparable to, and sometimes exceed, cast or even forged equivalents, especially for complex geometries. We ensure material certification and quality.

-

Q: What post-processing options does GreatLight offer for 3D printed organizers?

- one: In addition to basic support removal, we offer a comprehensive suite of: Sanding/Polishing (Various abrasive grains make the surface smooth), Bead/Media Blast (matte finish), Painting/dying (plastic), Electroplating/anodizing (corrosion resistance of metal, color), and even accuracy CNC machining Achieve tight tolerances on critical surfaces. We select finishes that offer the best functionality and aesthetics.

-

Q: I have a unique industrial part that is difficult to machine. Can GreatLight help with metal prototyping?

- A: Yes, this is our core expertise! Complex geometries, internal channels, lightweight structures and high-performance alloys are the strengths of SLM. GreatLight specializes in solving challenging metal rapid prototyping and production problems. Send us your CAD model and our engineers will advise on printability, material selection, and deliver a high-quality functional prototype or end-use part.

- Q: How quickly can GreatLight deliver custom prototypes or parts (such as organizers)?

- one: Turnaround time depends on complexity, materials and quantity. However, GreatLight prioritizes speed. Simple polymer prototypes can be shipped within days. Metal SLM parts usually with standard surface treatment 1-2 weeks. We offer expedited options and provide a clear project timeline up front.

Ready to streamline your shop or turn your complex parts vision into reality? Discover Gretel’s potential!