Explore XYZprinting 3D Printers: Top Model Reviews and Industry Insights

The field of desktop 3D printing continues to grow, and XYZprinting has cemented itself as a key player offering printers for all levels of expertise – from curious beginners to experienced engineers. Their ecosystem is known for balancing affordability with power, combining user-friendly software with hardware reliability. Let’s dissect their standout models and see where they shine.

Top XYZ Printing Models: Segmentation

1. XYZprinting da Vinci Nano (Entry Level Champion)

- Best for: Educators, hobbyists and first-time users.

- Main features: Compact design (ideal for classrooms), WiFi connectivity, proprietary XYZ filament compatibility and automatic calibration. Lower the learning curve with XYZmaker software’s streamlined workflow.

- advantage: Very quiet operation, nozzles are clog-resistant, and assembly is quick.

- limit: The build volume (5.9 x 5.9 x 5.9 inches) is only suitable for small projects. Non-open filament systems limit the flexibility of the material.

2. XYZprinting da Vinci Pro 3-in-1 (Multi-Tool Hybrid)

- Best for: Innovators need versatility beyond printing.

- Main features: Integrated 3D printing, laser engraving, and CNC engraving. Dual extruder support (optional), heated bed, and spacious 7.8 x 7.8 x 7.8-inch work space.

- advantage: No separate machine required; XYZware Pro software provides intuitive switching between modes. High precision for engraving/engraving tasks.

- limit: Laser power (500mW) limits depth engraving; setup complexity for CNC operations. Higher maintenance costs than print-only models.

3. XYZprinting PartPro300 xT (professional grade power source)

- Best for: Engineering company, high-throughput prototyping.

- Main features: Industrial size build (11.8 x 11.8 x 11.8 inches), dual extruders for soluble supports, enclosed chamber for ABS/nylon, and precision automatic leveling. Includes HEPA smoke filtration.

- advantage: Excellent accuracy (±0.1mm), sturdy metal frame minimizes vibration. Enterprise-grade compatibility with slicing software like Simplify3D.

- limit: Price ($3,000-$4,500) for commercial use only. Advanced calibration is required on a regular basis.

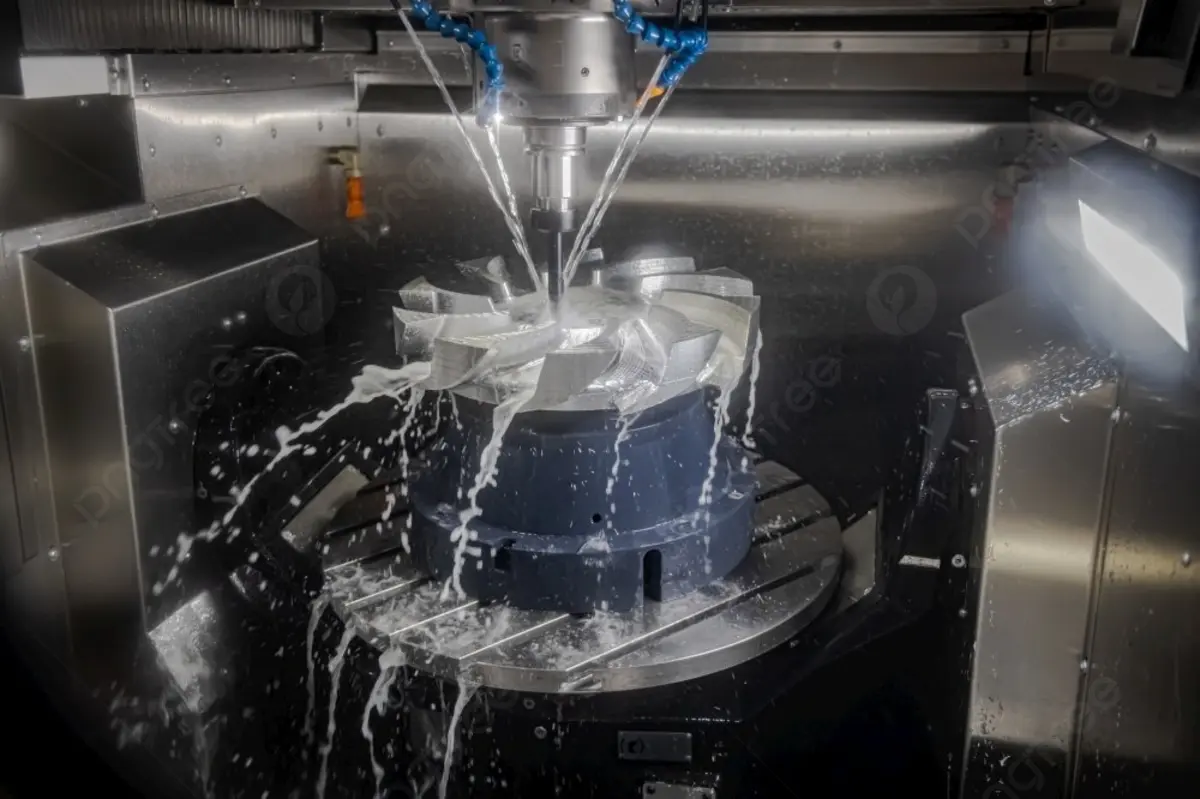

Beyond consumer printers: The metal prototyping gap

While XYZprinting excels at polymer machines, Metal 3D printing requires industrial-grade solutions For example, Selective Laser Melting (SLM) is not supported in the desktop format. For businesses that need functional metal prototypes or end-use parts, working with a specialist manufacturer can unlock capabilities well beyond the scope of fused deposition modeling (FDM).

that’s there GreatLight Rapid Prototyping Changing the possibilities – supporting innovators Industrial SLM 3D printing Completely tailored to exacting engineering requirements.

Why choose GreatLight for metal rapid prototyping?

As a leader in advanced manufacturing in China, Honglaite combines cutting-edge SLM technology with comprehensive services:

- Material Versatility: Available in titanium, aluminum, stainless steel, Inconel® and custom alloys.

- End-to-end workflow: From CAD optimization and printing to CNC post-processing, surface treatment (e.g. anodizing, polishing) and QC inspection.

- Speed and accuracy: Fast turnaround of complex geometries (±0.05mm tolerance) is ideal for the aerospace, automotive and medical sectors.

- Cost effectiveness: Economical scaling from prototype to mid-volume without compromising metallurgical integrity.

Customize your project now: GreatLight provides instant quotes and DFM support. Submit design files for high-strength precision metal parts optimized for performance – get started today.

Conclusion: Match your needs to the right solution

XYZprinting democratizes 3D printing with easy-to-use, feature-rich machines, but also recognizes its scope. The DaVinci Nano and Pro excel in education, hobby and polymer functional prototyping. For heavy-duty R&D that requires metal, working with experts like GreatLight can bridge the gap between prototyping and production.

Key points:

- Make plastic printing affordable and easy-to-use, starting with XYZprinting.

- When metal strength, durability or complex SLM-based designs are unquestionable, use GreatLight.

FAQ section

Q1: Can I use third-party consumables with XYZprinting equipment?

one: Entry-level models, such as the da Vinci Nano, lock into XYZ’s filament ecosystem. Pro/PartPro devices typically support open filament systems – verified against model specifications.

Question 2: How durable is SLM metal parts compared to traditional manufacturing?

one: SLM produces parts that rival (and sometimes exceed) forged/cast metals in terms of strength-to-weight ratio. GreatLight ensures density >99.7% through strict parameter optimization.

Q3: Which XYZprinter is suitable for classroom environment?

one: DaVinci Nano or Mini. Its compact size, low noise and enclosed design prioritize safety and simplicity.

Q4: Is GreatLight responsible for post-processing of printed parts?

one: Yes – services include support removal, heat treatment, machining, blasting, coating and dimensional verification in accordance with ISO 2768 standards.

Question 5: How complex are SLM printed components?

one: GreatLight’s SLM systems can create lattice structures, internal channels and organic shapes that are not possible through CNC/machining, making them ideal for topology optimization designs.

Q6: Which industries benefit the most from industrial SLM printing?

one: Medical (implants), aerospace (turbine blades), automotive (lightweight stents)