The advent of 3D printing has revolutionized the way we design and manufacture a variety of products, including electric boxes. Traditionally, electric boxes are made using traditional manufacturing methods such as casting, processing or injection molding. However, these methods have several limitations, including high production costs, longer lead times and limited design flexibility. 3D printed electrical boxes provide game-changing solutions to these challenges, allowing rapid production of complex geometries, reducing material waste, and increasing design customization.

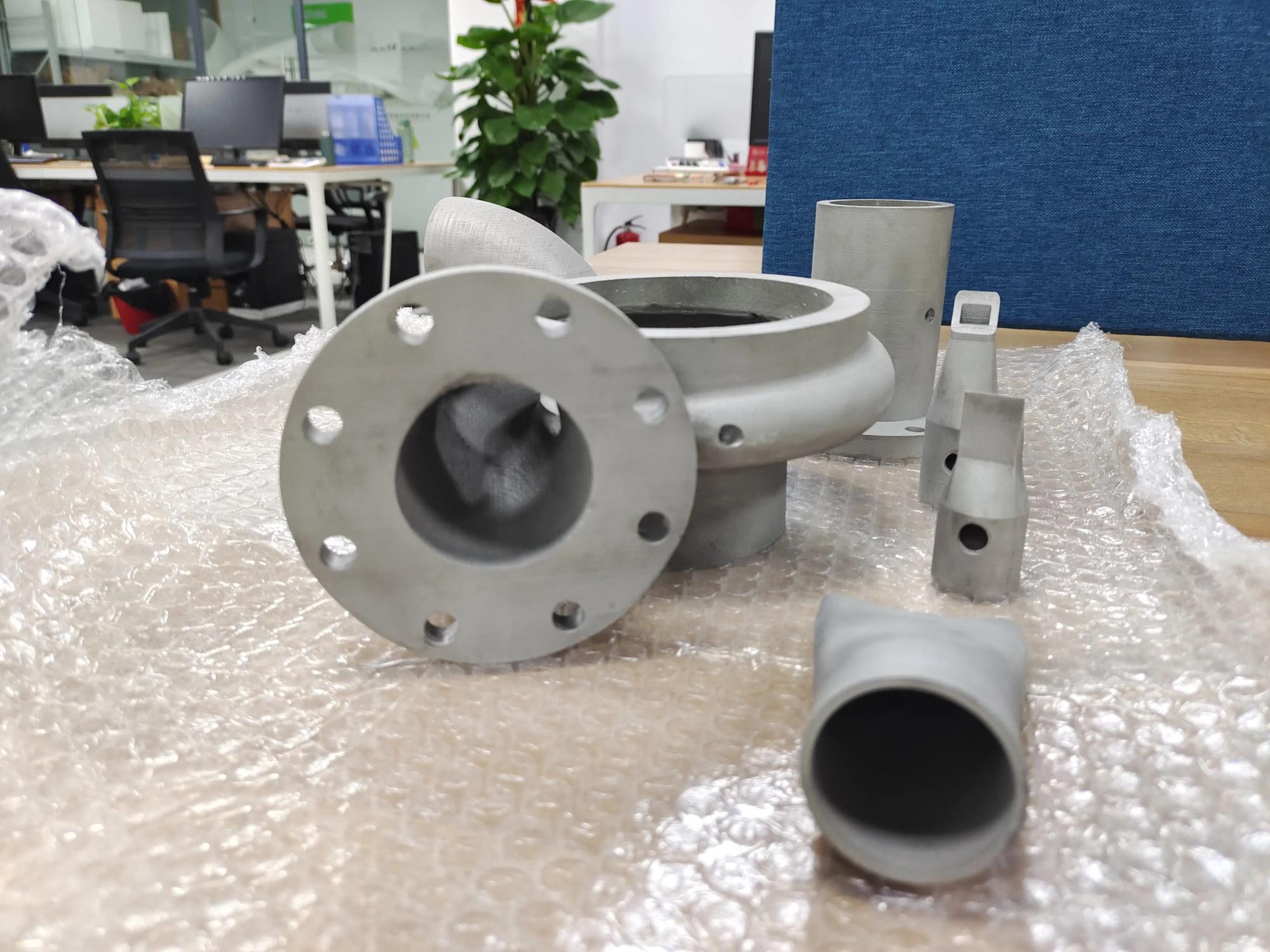

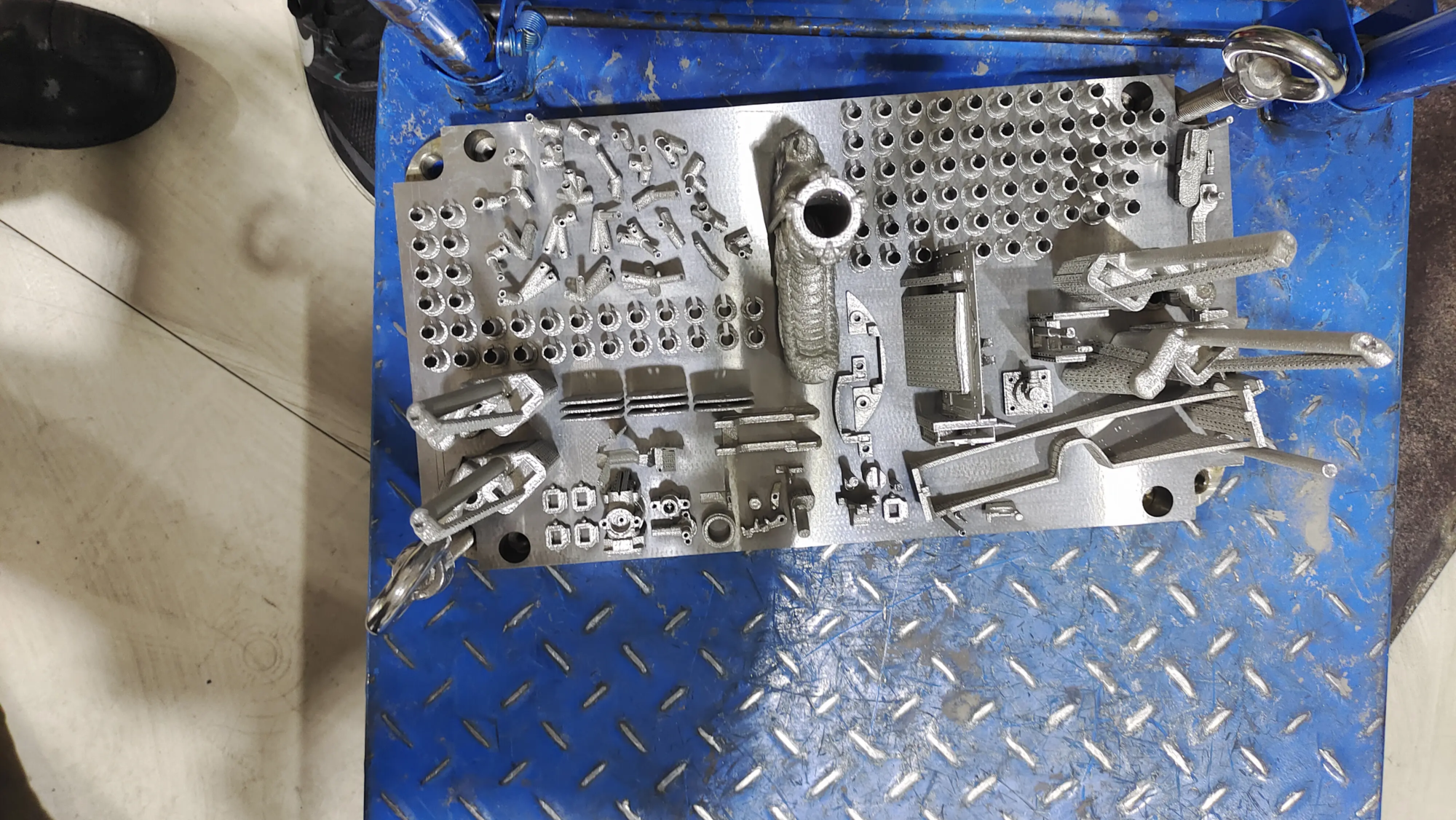

At Greatlight, is the leading rapid prototyping manufacturer from China, we specialize in providing high-quality 3D printed electric boxes to meet the various needs of our customers. Our state-of-the-art SLM (Selective Laser Melting) 3D printers and advanced production technology enable us to produce metal parts with excellent accuracy, finishing and mechanical properties. In addition, our one-stop post-processing and finishing services ensure that the final product meets the required standards of quality, functionality and aesthetics.

One of the important advantages of 3D printed electrical boxes is their ability to accommodate complex geometries and designs. Unlike traditional manufacturing methods that usually require expensive tools and molds, 3D printing can create complex shapes and structures without any additional expense. This design freedom allows engineers and designers to optimize the performance, efficiency and safety of the electrical box while also reducing material waste and weight.

Another benefit of 3D printed electrical boxes is their fast production time. Using traditional manufacturing methods, it can take weeks or even months to produce an electric box. By contrast, 3D printing can produce electrical boxes within a few days, which is particularly useful for prototyping, testing and verification purposes. This accelerated production time also enables the company to respond quickly to market demand, thereby reducing market time for new products and services.

In terms of materials, 3D printed electrical boxes can be made of various metals including aluminum, copper and stainless steel. Each material offers unique properties such as conductivity, corrosion resistance and strength that can be tailored to specific applications and industries. At Greatlight, we work closely with our customers to select the most appropriate materials and design parameters to ensure that the final product meets its specific requirements.

In short, 3D printed electrical boxes provide revolutionary solutions for companies seeking to improve the design, functionality and productivity of electrical systems. 3D printing has the ability to adapt to complex geometric shapes, fast production time and material flexibility, thus helping to transform the electrical industry. At Greatlight, we are committed to providing high-quality 3D printed electrical boxes that meet the evolving needs of our customers and invite you to explore our services and expertise to take your electrical system to the next level.

FAQ:

Q: What is the typical lead time for producing 3D printed electric boxes?

A: The lead time for producing 3D printed electrical boxes may vary depending on the complexity of design, materials and production. However, with the most advanced SLM 3D printers, we can produce power boxes in a few days.

Q: Can 3D printed electric boxes be customized according to specific materials and designs?

A: Yes, 3D printed electrical boxes can be customized to specific materials and designs. We work closely with our customers to select the most appropriate materials and design parameters to ensure that the final product meets its specific requirements.

Q: Are 3D printed electric boxes more expensive than traditionally made electric boxes?

A: The cost of 3D printed electrical boxes may vary depending on the complexity of design, materials and production. However, 3D printing can save a lot of money when it comes to reducing material waste, energy consumption and production time.

Q: What is the typical application of 3D printed electric boxes?

A: 3D printed electrical boxes can be used in a wide range of applications, including aerospace, automotive, industrial automation and consumer electronics. They are especially useful in situations where complex geometry, high performance and rapid production are required.

Q: How do I start with a 3D printing electric box?

A: To get started with 3D printed electrical boxes, just contact us on Greatlight and our team of experts will work with you to understand your design requirements, select the most appropriate materials and production parameters, and produce high-quality 3D printed electrical boxes that meet your needs.

ISO 9001 Factory