Embrace the future of role-playing: Mastering 3D printed space armor

Thanks to the revolutionary power of 3D printing, the grim darkness of the distant future has never felt close. For role-playing enthusiasts, creating the awesome powerful armor of Warhammer 40,000 Space Marines is no longer an impossible dream left for elite prop makers. With careful planning, the right technique and some elbow grease, you can build your own suit worthy of the emperor. This guide delves into the key steps and precautions for making plays of 3D printed space roleplaying.

1. The Holy Grail: Detailed Planning and Design

- Source your blueprint: Start with the exact 3D model. Websites like Thingiverse and Cults3D offer free and paid STL files. Prioritize models designed specifically for role-playing – look for pre-burned parts, optimized geometry for printing and wearing, and clear segmentation. Verification ratio! Compare the key measurements (shoulder width, bust, forearm length) to your own body. Software like Blender or Meshmixer can make basic scaling modifications and cut large pieces into manageable parts.

- Design wearable capabilities: Remember, this is a wearable outfit, not a static statue. factor:

- Mobility: How will you bend your knees? How many shoulder pronunciations do you need? Design or modify joints accordingly.

- Filling and comfort: Integrate space inside the high-density foam-filled assembly at the pressure points (shoulders, elbows, knees, overhead). Plan accessories for belt or buckle.

- Visibility and ventilation: Helmet visors need to be tinted mesh or acrylic. Strategy-placed vents (hidden behind barbecue details) are essential for airflow to avoid overheating.

- Modular components: Break down the armor into logically printable parts (e.g., shoulder baul bone, front/back of the torso, thigh guard, shin guard, gloves). Plan how to securely connect every piece with an internal belt, buckle or strong magnet. Carefully document the plan.

2. Select your arsenal: Printer Technology, Materials, and Settings

- Printer selection: Fusion deposition modeling (FDM) printers such as Prusa or Creality models are the most common and affordable for large armored pieces. Their size needs to be carefully sliced.

- The solution is important: The layer height is between 0.15mm and 0.3mm, providing a good balance of detail and speed. Smaller heights are equal in surfaces, but greatly increases printing time.

- Filling strategy: Do not print solids! Use a fill density of 10-20% with powerful patterns such as ability to balance weight, strength and material savings. Add filler (~30%) at critical stress points (belt attachment, joint area).

- Support structure: It is crucial for overhanging. The support of a tree can usually save material and be easier to remove than standard support, but requires careful placement in the slicer. Complex geometry may require custom support using meshmixer.

- Material selection:

- PLA: First choice for beginners. Advantages: Easy to print, cheap, low warpage, width range. Disadvantages: It may become vulnerable in cold weather, susceptible to heat (such as hot car or conference lights), and has a lower impact resistance.

- PETG: Major upgrades. Advantages: More durable, softer, heat resistance, higher impact strength, water resistance than PLA. Cons: Printing can be slightly strict and usually costs more.

- ABS/ASA: Best for durability and heat resistance. Advantages: Very powerful, grindable, paintable, can handle higher temperatures better. Disadvantages: A printer housing, usually a heated chamber, is required to prevent severe warping on most of the time, and the discharge of smoke requires excellent ventilation.

- TPU (Flexible): Strategically used for components that require bending or comfort, such as finger joints or fill bases. Requires slower printing speed and careful calibration.

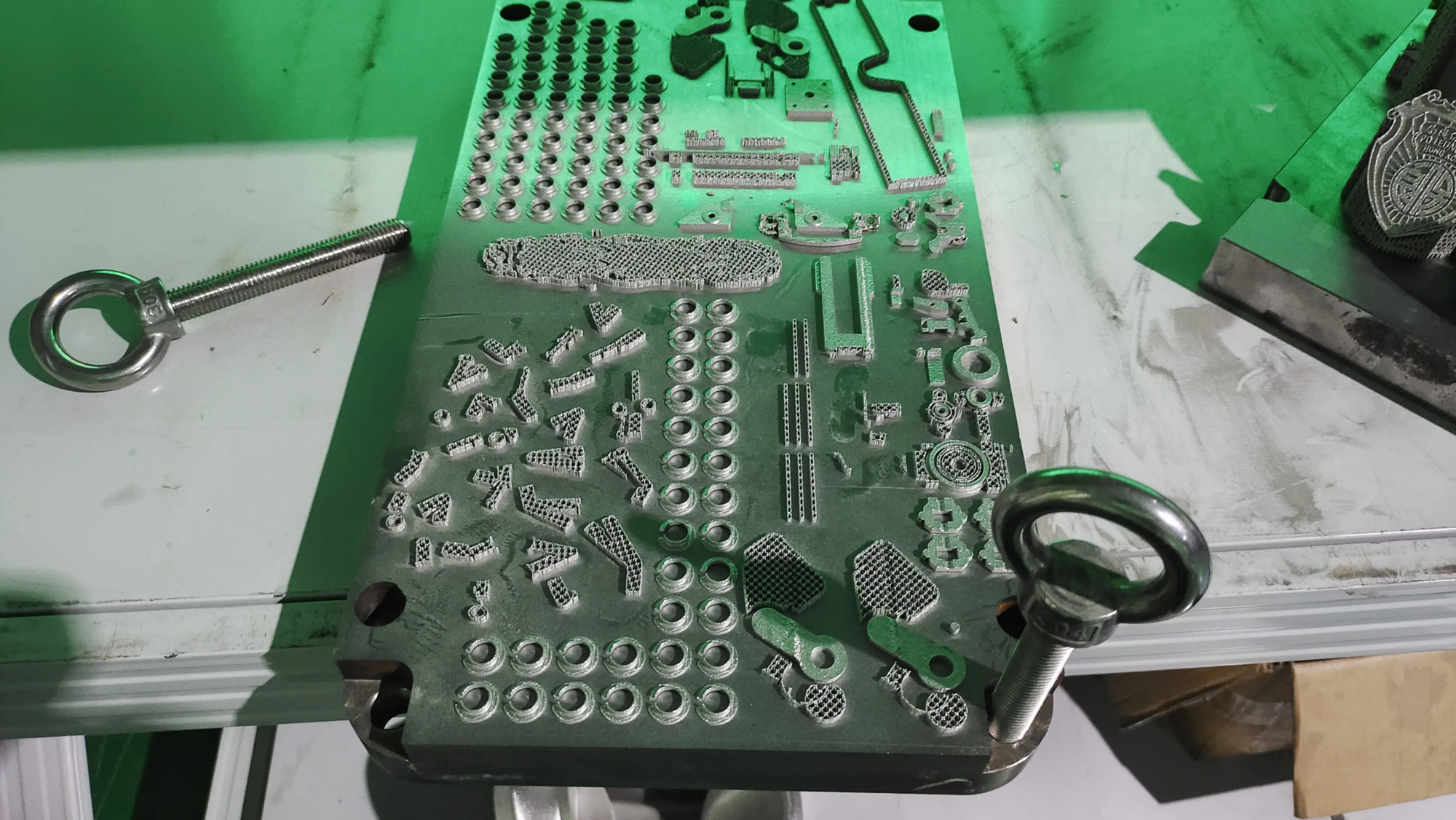

- Expert tips for large projects and durability: For mission-critical components that require maximum durability, dimensional accuracy and professional finishes (helmets, weapons, intricate shoulders), consider Industrial grade materials and technology. Professional rapid prototyping services such as Greatlight and its advanced selective laser melting (SLM) capabilities can produce exceptionally powerful, complex metal parts. While coats are more expensive than plastic printing, outsourcing critical structural components can greatly improve life and realism.

3. Empire Forging: Advanced Printing Technology

- Slice wisely: Master your slicing software (Cura, Prusaslicer). Adjust settings for each section – Larger, simpler parts may use higher layer heights, while detailed bits require finer resolution.

- The power and appearance of the East: Print curved parts so their strongest axes align with the expected stress – usually perpendicular. The oriental surface will be highly visible (helmet, chest eagle) to avoid the main support ahead.

- Printing Management: Monitor large prints! Power failures can be catastrophic. Consider a UPS. Ensure stable bed adhesion (clean bed, proper temperature, edge/raft). Take the initiative to manage spaghetti monsters!

4. Clear Heresy: Perfect Advanced Postprocessing

This is where your armor transforms from printed objects to imperial relics.

- Support removal: Carefully use the rinsing cutter and needle files. Dremel (Orbital Sander) speeds up initial support scar removal, but may melt the plastic; use a lower speed to avoid staying in one place. Wear a respirator!

- Gap filling and seam hiding: Temporarily assemble adjacent sections to identify gaps and mismatches. use Epoxy putty (like Milliput or something green) is carved into gaps and joints. The sand is smooth after curing. CA glue + accelerator Work for hairline cracks.

- Advanced polishing: Start the rough (80-120 grit) to keep the major defects and putty seams horizontal. Gradually progress through gravel (220, 320, 400, 600) to make the surface smooth and paintable. Wet sand can reduce dust.

- Start and spot correction: spray High fill primer Even on all debris. This reveals every flaw! Grind again where needed (over 400 gravel). Repeat prime cycles until completely smooth. Don’t skip this!

- Painting and weathering:

- Bestcart: Use high quality hobby acrylic or spray paint designed for plastic/car use. Apply a thin layer. The spray gun provides the best results for smooth gradients and base materials.

- detail: Hand-painted badges, pure seals, lenses (using gem paint as realistic lenses), metallic materials (dry brushing is great).

- weathering: Make it a battle! Use similar:

- Dry brushed metal paint at the edges, which can wear.

- Wash (sparse dark paint or professional wash, such as grey oil/agrax Earthshade, for dirt and shadows.

- Oil stains and striped dirt effects.

- Sponge on darker/rust colors for random fragmentation.

- Dust/muddy pigment to boots and calves.

- Clear Coating: Protect your masterpiece! Use durable matte varnish as the final weathering step. Gloss varnish before applying decals/transfers or a specific part needs gloss (lenses, certain metals). The last satin varnish that takes into account the balanced sheen.

5. Suitable for War: Final Assembly and Wearability

- Internal comfort: The line area contacts the skin with soft fabric (velvet, suede) or sews it onto the foam fill. Use sweat straps in helmets.

- Wire Harness System: Create an internal wiring harness for the torso core using a sturdy vest or belt system. Secure the shoulder baul bone, chest plate and back plate to this seat belt. Leg armor is usually attached to belts or padded shorts via buckles or Velcro belts. Test weight distribution!

- Modular connection: Use strong neon magnets (N50-N52 grades, Always wrapped In plastic or epoxy to prevent cracking during use) reinforce with Velcro or quick release buttons. This makes it easier to transport, dress and break down.

- Technology integration: Add LEDs to glasses, power packs, or weapon glow. Plan the battery pack and wiring carefully. Small USB power bank is very convenient.

- Mobility Practice: Before the major incident, I walked down, sat down, and raised my arms repeatedly. Refining belts and fillings based on comfort and function. It’s a lot of hydration when wearing it – it’s very hot there!

Conclusion: Forge your legend

Building a 3D printed spacecraft suit is a huge undertaking that combines digital art, craftsmanship and body endurance. The journey from digital models to weathered battle boards is demanding but incredibly beneficial. Embrace the challenges of planning, precision printing and meticulous finishing. Don’t be afraid of iteration, learn from mistakes, and unleash your creativity during the drawing phase. Remember, Emperor protection, but quality glue, solid printing and smart engineering protection you A long day at the conference. Whether you choose to print yourself completely or leverage Professional rapid prototyping expertise for critical components that require extremely high durability and precise metal finishes (such as Greatlight’s SLM technology for perfect helmets or weapons)Your dedication will forge a role-playing, inspire awe and embody a spirit of fanaticism. Now, fit and claim glory!

FAQ (FAQ)

-

Q: How much does it cost to 3D print a complete marine suit?

- one: Cost varies greatly depending on size, material (PLA vs. PETG vs. outsourcing metal), printer efficiency, filling and whether or not you need to buy the printer itself. Self-printed PLA: $300-$800+ (material/electricity). Self-printed PETG: $400-$1000+. Outsourcing critical metal components can significantly increase costs but add durability/realism. Factors (primer, paint, glue) and hardware factors such as foam, belts and buckles.

-

Q: How long does it take to print a complete suit?

- one: This is a long project. Printing time depends on the number of printers, layer height, fill and part complexity. Expected Hundredsit is possible to surpass thousandthe total printing time of a complete suit printed on an average FDM printer in a medium setup several hours. Using multiple printers greatly reduces this.

-

Q: PLA, PETG, and ABS/ASA- Which is best for space naval armor?

- one:

- PLA: The easiest startup, perfect for learning, suitable for cool climates/indoor wear. The weakest options are in terms of heat and impact.

- PETG: The best overall balance for most role players. Stronger, more flexible, and better handle heat/pressure. Highly recommended.

- ABS/ASA: The most durable and heat-resistant, the sand is beautiful. Best for demanding props/professional appearance if You have closed printer setup and ventilation expertise. Avoid no shell.

- one:

-

Q: How to stop my large format warping?

- one: Warpage is caused by uneven cooling/shrinkage. Use it to fight: clean, Correct balance Bed; apply reinforced adhesive (glue sticks, hair spray, special bed adhesive); use edge (Wide bonding ring around the base); bed temperature rises moderately; use one shell Maintain a stable, water-free, warm environment (critical for ABS/ASA); ensure the first layer is slow and perfect.

-

Q: How do I join the big chunks smoothly and strongly?

- one: Forgot a separate glue! Reliable method:

- Plastic welding: Use 3D pen and matching filament "welding" Seams or fill gaps deep inside.

- CA glue + accelerator + reinforcement: Adhesive seams and then along in Fiberglass tape + epoxy with strips of filament (melt using welded iron-colored fixing material) or soaked in it.

- Epoxy resin: After surface preparation, slow fixing of the two-part epoxy (such as JB welded plastic bolts) provides a very firm bond (rough).

- one: Forgot a separate glue! Reliable method:

- Q: When should I consider professional rapid prototyping services?

- one: Professional Service (like Great) becomes advantageous in the following situations:

- You need Extreme durability Or typical FDM plastics cannot have heat resistance (e.g., often hit thin armor sections, heavy props).

- you need to Higher dimensional accuracy and finish Look directly at complex parts (detailed helmets, gorgeous weapons, articulated joints).

- You lack the printing capability/time for critical components (see for example "Cost over $1,000").

- You want to join Industrial grade metal components (via SLM or SLS) Weight, authenticity and unparalleled strength in key areas. Their one-stop post-processing service then offers ready-made paint or assembled finishes. It’s an investment, but ensures flawless, lasting results for mission-critical role-playing parts."

- one: Professional Service (like Great) becomes advantageous in the following situations: