The holographic projection improves the effectiveness of 3D printing of the volume and can considerably reduce energy consumption.

In a 3D Tomography volume printing process (VAT), a laser beam is projected in a rotary resin container until the accumulation of energy at certain specific points exceeds a threshold, causing the healing of the resin. Compared to traditional hierarchical 3D printing methods, TVAM has the advantage of being able to create objects in a few seconds. However, this method is less effective, with only around 1% of the light energy used for resin hardening.

On February 11, 2025, a research team from the Federal Institute of Technology (EPFL) in Lausanne, Switzerland and the University of South Denmark, developed a method that considerably improved the efficiency and resolution of VAT. Using holographic projection, researchers are able to considerably reduce energy consumption while improving the accuracy of details. The results of the relevant research have been published in the journal Nature Communications under the title “Additive manufacturing of Holographic Tomographic Volume”.

A research team led by Christophe Moser and Jesper Glückstad solved the problem by developing a method called holotile to generate three -dimensional holograms. The traditional TVAM method code information in the amplitude of the projected light wave, while the new method uses the phase of the light wave. This allows better control of the light projection depth and improves spatial resolution. Compared to previous studies, the method has improved the effectiveness of light projection of at least 20 times while maintaining the high precision of the final product.

In experience, the research team used a continuous wave wave diode of 405 Nm of 40 MW (combined with a monomod fiber with an efficiency of 33%), with success a print time of less than 60 seconds and reliably reaching 31.35 μm of negative characteristics. (hole). The reason why the print time is so short is that the light engine is very effective.

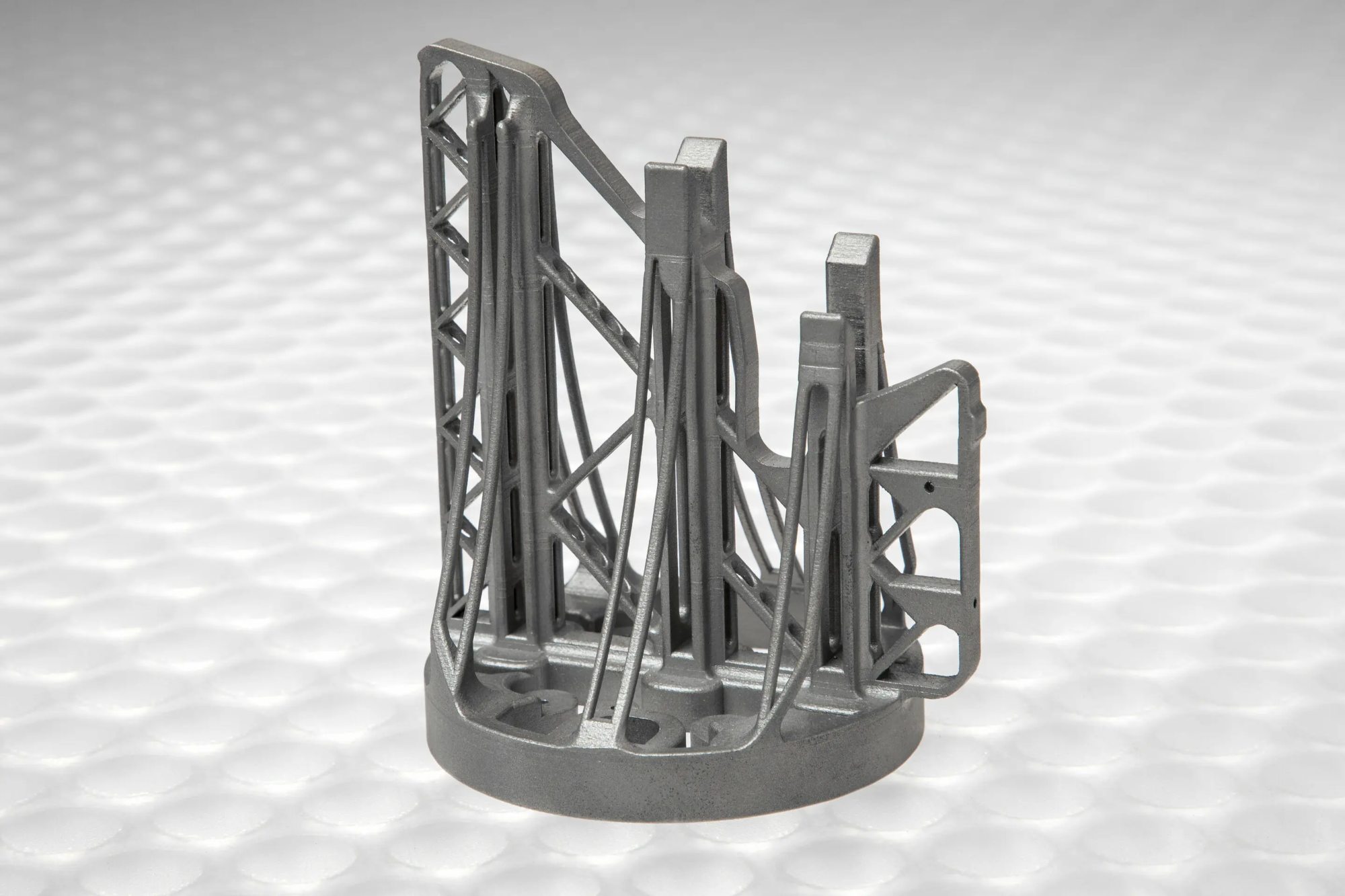

Using this technique, researchers have managed to print complex 3D objects such as miniature ships, spheres and art designs in less than 60 seconds, and have considerably reduced the use of optical power. The required energy is only some of the previous parts. In addition, the holotile technology adopted eliminates unnecessary light interference through a “tiling” method, improving image quality.

Another promising area of application of this technology is biomedicine. The team plans to use VAT holographic technology to print complex biological structures such as realistic tissue and organs models. Because the holographic beam has self-healing properties, it can be used with bioresin and hydrogels without affecting precision due to the diffusion effects.

For the future, researchers hope to further improve the effectiveness of the method. One of the objectives is to eliminate the need for rotation of resin containers, and objects can be formed simply by projecting the hologram on the liquid. This will simplify the process and make it more suitable for large -scale applications.