Human beings always have the dream of conquering space, and each technological advancement brings us closer to this objective. Among many innovative technologies, 3D printing has become significant support for space industry in recent years. In addition, this technology has been used in the aerospace field for a long time.

In 2014, the first 3D printer was sent to space, marking an important turning point in applying this technology in extreme environments. Since then, its scope of application has continued to develop – simple maintenance and initial experiences of microgravity environments to the current design and manufacturing of rockets, and has even opened new possibilities for in situ manufacturing.

So why use 3D printing technology in space missions? Let’s follow the resource library to find out which key applications 3D printing is in space exploration.

Spatial transport optimization

1、Optimization of rocket components

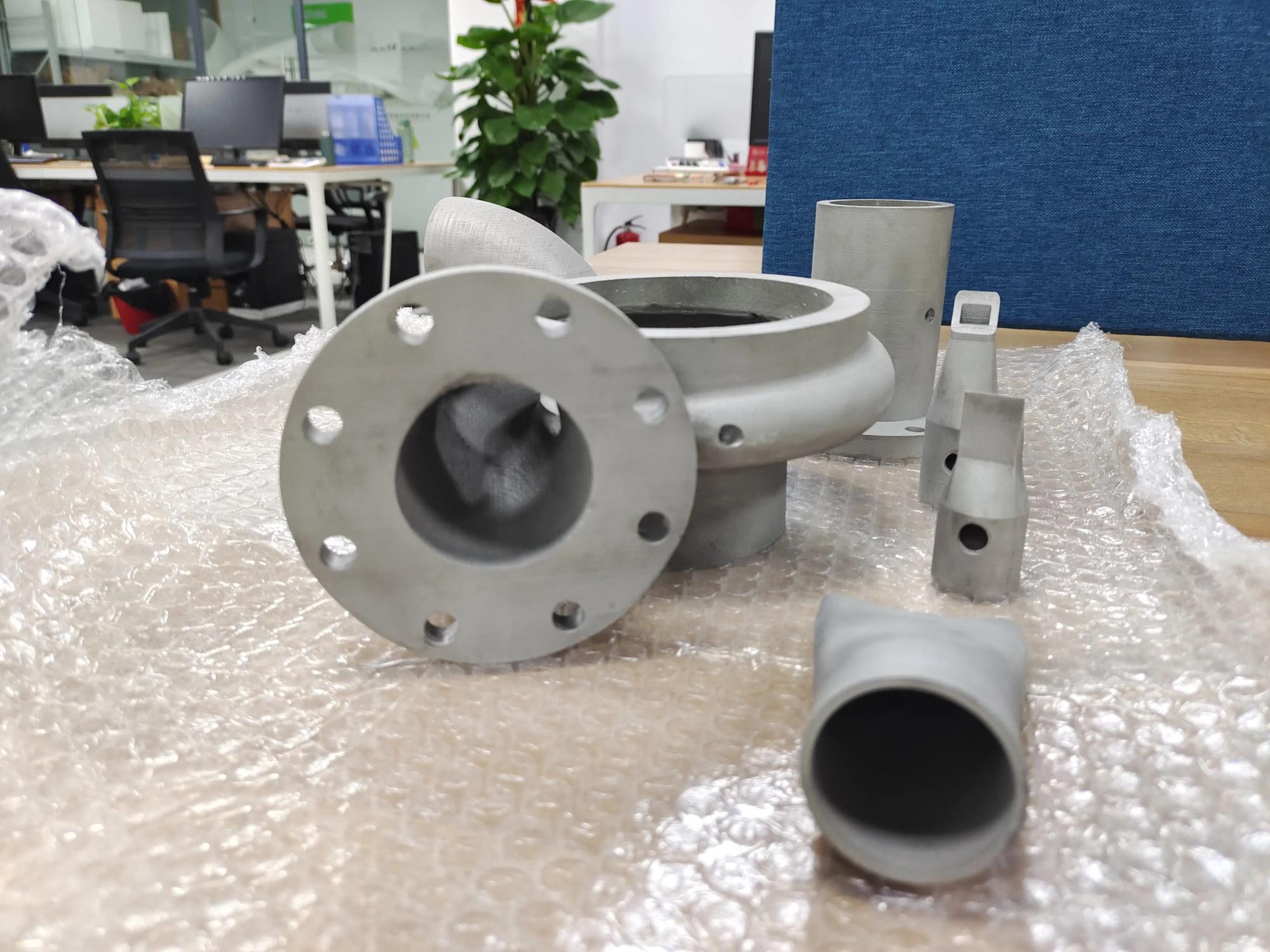

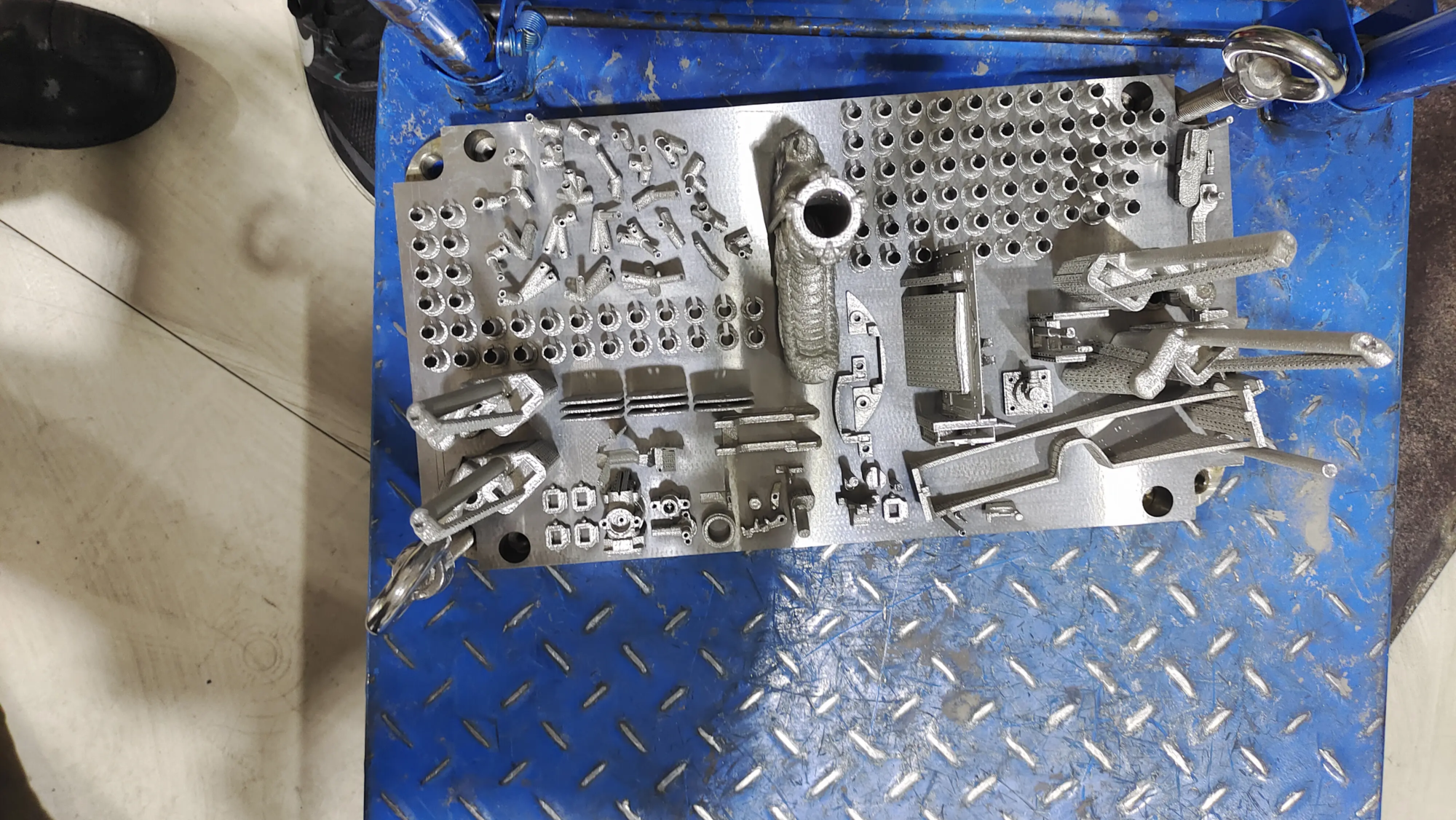

In spatial exploration, each gram of weight is crucial. The lighter a rocket or satellite, the lower the launch cost and the higher the efficiency. By reducing the weight of the aircraft, fuel demand can be reduced and more space can be designed to transport practical equipment. 3D printing offers an ideal solution for this: it can make personalized parts optimized topologically, taking into account both strength and weight.

With the help of the design of additive manufacturing (DFAM), in particular topological optimization technology, complex structures that cannot be carried out by traditional methods can be created. The typical case is the cooling channels of rocket engines – the tiny conduits are responsible for the evacuation of intense heat around the combustion chamber. With 3D printing, these pipes can be directly integrated inside the components, while traditional machining or injection molding are too expensive or simply impossible to achieve.

2、Use new materials to improve performance

Spatial materials must withstand extreme environments: high temperature, radiation, pressure changes, thermal shock, etc. Today, 3D printing can use a wide range of advanced materials, including titanium alloys, aluminum alloys and Nickel Nickel alloys, which are known for their light and heat resistance.

Composites reinforced by fiber which balances resistance, flexibility and light; And technical ceramics such as zirconia – which are even conductive at extremely high temperatures.

3、Simplification and cost control assembly

3D printing technology considerably simplifies the manufacturing process of spaceships thanks to the integrated molding. Traditional manufacturing requires complex systems that assemble thousands of parts and can now be made entirely thanks to 3D printing.

For example:Sab Aerospace successfully 3D has printed a monolithic rocket nozzle, while traditional processes require the assembly of thousands of individual parts.The relativity space has reduced the number of parts of its 1,000 Terran rocket to 3D printing.This manufacturing method reduces not only the complexity of the assembly, but also considerably shortens the production cycle, making the development and iteration of the prototypes more efficient and economical.

Improve the life of astronauts

4、Manufacturing of spare parts in microgravity environments

3D printing supports the direct manufacturing of articles in space, considerably reducing dependence on recharging missions in terms of the land which take time and by labor. In 2024, the International Space Station managed to make the first metallic part, marking that this technology passed the verification of the space environment.

5、Spatial food print

In response to the challenges of food supply of long -term space missions, 3D printing can convert the dough or powdered ingredients to personalized meals. Tests at the International Space Station have confirmed that this technology can synthesize meat in microgravity environments and reach personalized nutritional ratios.

6、Medical and biopritis equipment

From personalized splints to surgical tools, 3D printing instantly meets the medical needs of space. Redwire has managed to print meniscus fabrics in a microgravity environment, throwing the basics of a future catering of space fabrics.

7、Spatial combination manufacturing

The spatial combination prototype developed by Axiom Space For Artemis Project combines CAD design, 3D printing and traditional sewing processes, demonstrating the manufacturing potential of personalized spatial protective equipment.

Accelerate space immigration

8、Spatial architecture and future habitat

To build a permanent base on the moon or on Mars, traditional construction restrictions must be overcome. 3D printing supports the use of in situ resources such as lunar soil to build special structures that can withstand radiation, extreme temperatures and low gravity, providing infrastructure solutions for space colonization.

From the manufacture of rockets to extraterrestrial basic construction, 3D printing reshapes the path of spatial exploration in all aspects. This technology not only improves the efficiency and security of the mission, but also makes it possible to the lasting existence of humans in space.