In the military field, flexibility and innovation are essential to guarantee successful operations in the world. With the advancement of technology, additive manufacturing (3D printing) gradually becomes an important tool for the Ministry of Defense in order to improve its capacity for preparation for the battlefield.

According to the resource database, the global additive manufacturing market in the aerospace and defense sectors is estimated at around $ 2.76 billion in 2022 and is expected to reach $ 17.9 billion by 2032, with an annual compound growth rate (CAGR) up to 20.48% (data source: research in wood). So what is the current situation of additive manufacturing in the field of defense? How does he develop? What challenges are they confronted with? This article will discuss in depth.

Government policies promote the application of 3D printing in the army

USA

The American government is one of the first promoters of the application of additive manufacturing in the field of defense. The US Department of Defense (DOD) published the additive manufacturing strategy in January 2021, aimed at improving the modernization of defense systems, improving material preparation capacities thanks to 3D printing technology and providing innovative solutions to soldiers on the battlefield. This strategy was also supported by the Biden administration, and the “AM Forward program” launched in May 2022 also favored the application of additive manufacturing in the army.

The additive manufacturing strategy of the US Defense Ministry includes five major objectives:

1. Integrate additive manufacturing in the Ministry of Defense and the Industrial Defense base;

2. Coordinate additive manufacturing activities inside and outside the Ministry of Defense;

3. Promote a flexible application of additive manufacturing;

4. Improve the professional capacities of additive manufacturing;

5. Ensure the safety of the additive manufacturing workflow.

Thanks to these initiatives, the Ministry of Defense hopes not only to benefit from itself, but also to support the allies, including technical training and data security solutions.

Since 2012, the investment of the American Ministry of Defense in Additive Manufacturing has continued to grow, from $ 300 million in 2023 to 800 million dollars in 2024, and should reach 2.6 billion by 2030. The scope of applications covers key components of submarines, 3D printed rockets, APACHE helicopters, 3D metal printers on ships navals and even the construction of military camps.

UNITED KINGDOM.

The British Defense Ministry (MOD) also actively promotes the application of additive manufacturing. In April 2023, the United Kingdom Agency in terms of equipment and defense support (DE & S) signed a contract with five companies to accelerate the maturation of additive manufacturing technology. In addition, the United Kingdom has launched the “Tampa project” to focus on the manufacture of metal additives to reduce the time of the supply chain and improve the manufacture of old parts.

Alexander Champion, additive manufacturing engineer at the British Defense Ministry, said: “The British Defense Ministry has conducted several additive manufacturing trials in the last decade. We are currently promoting additive manufacturing as part of an advanced manufacturing tool box.” For example, British engineers also used 3D printing technology to make hospital pipeline accessories.

Other countries

Australia, Europe and China also actively explore the application of additive to national defense. The Australian army cooperates with SPEE3D to use cold spraying technology to make components of military vehicles.

Thanks to feasibility studies, the European Defense Agency (EDA) stressed that additive manufacturing has great potential in the maintenance of battlefields, the reduction of logistics charges and the improvement of sustainability. The Chinese people’s liberation army also uses 3D printing technology to test the maintenance of weapons remotely and transport 3D printed parts via drones.

Specific application of additive manufacturing in national defense

3D printing of the composite material:Composite materials are very favored in aerospace and defense fields for their light and high resistance properties. For example, composite materials can be used to make helmets, weapons, electrical components and aircraft spare parts. The US Air Force uses composite 3D printing technology to make spare parts for the B-52 bomber, the Super Galaxy C-5M carrier and the B-2 stealth bomber to reduce weight and extend the lifespan.

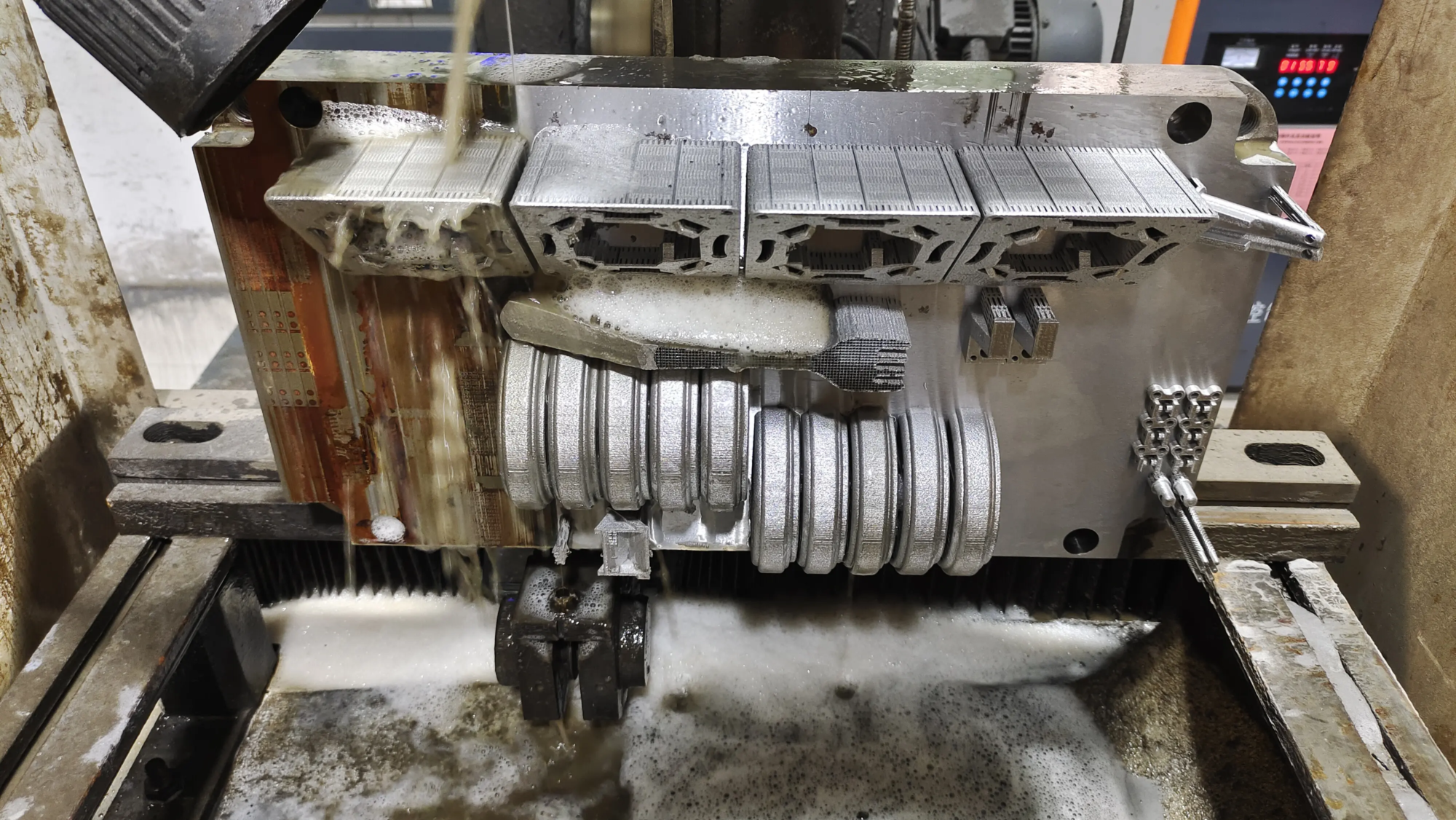

3D metal printing:3D metal printing is one of the fastest growth technologies in the defense field. The American navy cooperates with SPEE3D and AML3D to use 3D metal printing technology to solve the supply chain problems for submarine components. In addition, the American navy has also installed metallic 3D printers on the USS Essex to make spare parts on site.

3D polymer printing: 3D polymer printing (such as FDM technology) is an introductory technique for soldiers to learn additive manufacturing. High performance polymers (such as PEEK and PEKK) are widely used in aerospace and defense fields due to their light and high resistance properties. The British Defense Ministry takes place in SLS printing and continuous carbon fiber strengthening technology to create more resistant terminal components.

Current challenges

Despite the major perspectives of additive manufacturing in the defense field, he is always confronted with certain challenges:

1. Standardization and certification: the lack of unified standards and certification process limits the application of additive manufacturing in key components.

2. Data security: 3D printing implies the transfer of digital files and how to prevent data violations and hacking is an important problem.

3. Technical training: soldiers and engineers must receive vocational training to make the most of additive manufacturing technology.

4. Digitalization of the supply chain: many old components lack digital design documents and require reverse engineering and digital reconstruction.

Future perspectives

The application of additive manufacturing in the defense will continue to grow. Countries like the United States and the United Kingdom have formulated clear additive manufacturing strategies, and NATO countries can follow suit. In the future, additive manufacturing will be combined with other advanced manufacturing technologies (such as the laser cut) to promote digital transformation in the field of defense.

In short, additive manufacturing changes the rules of the game in the field of defense, from the optimization of the supply chain to the innovation of the battlefield, with an unlimited application potential. With the continuous progression of technology and political support, additive manufacturing will become an essential part of the future national defense.